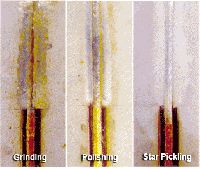

stainless steel pickling

Pickling and Passivation process ensures corrosion resistance and removes free ion contamination left on the SS surface from fabricating and machinery. These contaminants are prospective corrosion sites resulting in premature corrosion, ultimately resulting in decline of component if not removed. Corrosion resistance of SS is because of the presence of 13 percent chromium in alloy. The chromium, with oxygen, forms a think chemically resistant passive layer of chromic oxide thus shielding the SS surface against corrosion. The passive layer generally forms again after abrasion. All mechanical treatments damage the topmost layer of components i.e.Structural modifications in top layers of SS,Development of in-built stress

...more

Rust Converter

Rust Converter 177 is an innovative product based on the latest technology in rust converters. The distinctive formula of this product accounts for its dual functionality. Rust Converter 177 is a single pack ready-to-use solution which on applying converts the existing steel rust into a stable metal complex by forming a polymeric film over it. The Polymeric film acts as a protective and passivative coating preventing further corrosion which in turn acts as an ideal base for painting.Rust Converter 177 reacts with all the layers and forms a stable non-reactive complex organo-metallic surface having bluish-black colour. In addition, this innovative product arrests the migration of ions, preventing electro-chemical corrosion process and prolongs the paint life for a reasonable period of time, resulting in considerable savings.

...more

portable welding anti spatter spray

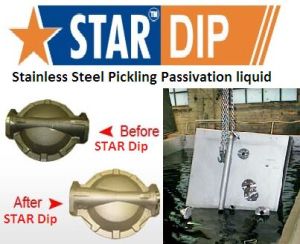

Pickling Passivation - Star Dip - Stainless Steel

We are offering pickling passivation - star dip - stainless steel. Star™ dip comes in liquid form and is used in cleaning complicated and non-reachable areas of ss components such as external and internal of pipes, wire rolls, and internal recessed areas of machinery. Parts of heavy machineries are dipped in huge tanks using chain pulley or circulation system for de-scaling and cleaning of pipelines. Star™ dip is circulated inside pipelines with the help of pumps. coverage per kg: approximately 40 sq. Ft application process: remove dirt and oil using star™ 100 degreaser. Add 50-75 gm/litres in water (1kg star™ 100 in 15-20 litres water), stir and dissolve. Apply liquid star™ 100 degreaser onto the surface for 5-10 minutes. Then rinse the surface area thoroughly with water. Just dip the objects (ss components) in the star™ dip tank. Use plastic tank in the process time only. Leave them for 5-20 minutes, depending on ss type and internal condition of ss parts & thickness of the scale. Then rinse the surface thoroughly with water. Apply star™ passivation (star™ pass 1) on the surface & leave it for 15 minutes. This will prevent from further contamination and corrosion. Remove and rinse the objects thoroughly with high pressure water. krystal undertakes job work contract for pickling and passivation of large ss vessels, equipments etc. ` star ' is approved by renowned third party inspection agencies as per international standards. star' chemicals are tested & approved under astm a380 standards by indian institute of technology (iit) bombay, india. refer our website for more details.

...more

Stainless Steel Cleaning Gel

We are offering stainless steel cleaning gel. stainless steel pickling passivation weld cleaning gel star chemicals for pickling & passivation of stainless steel. " star gel " (paste / gel form) " is used to clean weld seams and surrounding areas. It is applied with brush without doing wire brushing or grinding or buffing. "star gel " is used to remove heavy scales, discolouration, annealing colours, rust particles near weld and welding affected area by heat. It helps to detect pinholes after welding. application process : apply " star gel " on stainless steel welded seam & nearby area with nylon bristles brush. Give contact time of 5 to 30 minutes depending on grade & thickness of ss and temperature of ss surface. Then, wash with water properly with light scrubbing with plastic scubber (if required) . And, get to tally silvery white surface without grinding or buffing. area coverage per kg : approx.90 to 100 meters of weld seam. star chemicals includes, star spray (semi-gel form) for cleaning pickling passivation of ss equipments; star dip (liquid form) ,used in cleaning complicated and non-reachable areas of ss components such as external and internal of pipes, wire rolls, and internal recessed areas of machinery. star pass-1 & star pass-2 for passivation of ss tanks & pipelines etc. krystal undertakes jobwork contract for pickling & passivation of s. S. Equipments, vessels at the site & it's approved by many third party inspection agencies. star chemicals are tested & approved by famous i. I. T. Bombay under astm a380 standards.

...more

Passivation Tank

MIG welding machine

Phase : Three Phase

Voltage : 220V

Automatic Grade : Semi-Automatic

...more

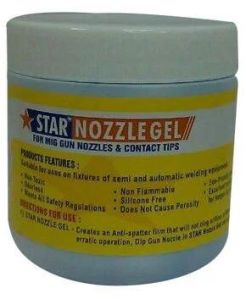

anti spatter star nozzle gel

Packaging Type : Plastic Jar

Anti Spatter Nozzle gel

STAR™ Nozzle Gel is Manufactured using supreme quality of materials and used for MIG Torch Gun Nozzle. With regular use, it extends the life of nozzle and contacts tips. It creates an antispatter film that does not clog orifices & threads. It eliminates erratic operation. STAR™ Nozzle Gel helps to prevent spatter and spatter build-up. It is suitable to use on semi-automatic and automatic MIG Gun Nozzle and other welding equipments. It is well-suited for fixture and jigs and prolongs life of nozzle tip by preventing spatter build-up on tip. Features: Non-toxic and non-flammable. Non flashing,biodegradable and paintable. Silicone-free for easy application. Odourless. Does not contain fluorocarbons or any ozone depleting chemical. Does not cause porosity. Eco-friendly Product. Excellent coling properties for longer tip and nozzle life. Usage Instructions: Dip the gun 1cm -2cm into STAR Nozzle Gel and start welding operation. Then remover the spatter which have been stick around the contact tip and inside the nozzle.Brush onto positioner and fixtures. Safety and Handling Precautions: Avoid contact with eyes as the material is slightly discomforting to the eyes. Avoid prolonged skin contact as it may cause drying of the skin. Use in a well ventilated area, however STAR NOZZLE Gel is not normally a hazard due to the non volatile nature of the product.

...more

stainless steel cleaning chemicals

Be first to Rate

Rate ThisOpening Hours