Utensils Laser Marking Machine

350,000 Per Piece

1 Piece (MOQ)

CNC Laser Cutting Machine

110,000 - 135,000 Per piece

01 Set (MOQ)

Best Deals from Laser Engraving Equipment

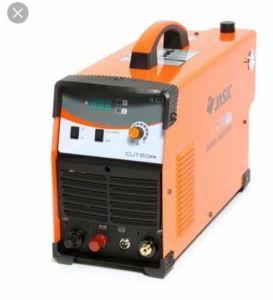

Plasma Cutting Machine

Get Price Quote

The Automated Plasma Cutting or what is more commonly known as A Series Plasma Cutting System is manufactured, supplied and also exported by us in bulk sized quantities. They come with current and pressure control as well. We have been in this field for some time now and have a huge client base to our credit. Kindly get in touch with our sales executives for further details regarding this product. Features : Front Panel Controls Mode selection Current control Pressure control Status display LED’s PressureStatus indicators Power switch on front With all the advantages of 1Torch and proven Thermal Dynamic’s reliability, the automated A-Series delivers the best in productivity, precision and performance : A powerful 80% Duty Cycle to handle all-day production cutting in the toughest environments. Light-weight, compact design and convenient mounting feet allow for easy mounting in any application. Valve-in-torch design reduces cycle time between parts and increases productivity. CNC Interface connection is located on the rear of the power supply offering “StartStop”, “ok to Move” and divided arc voltage signals. Full arc voltage is available using an internal terminal connection. Software automatically detects the torch that is attached and switches between automation and manual modes. Dedicated automation software improves cycle time and performance in many applications. The A-Series systems include the SL100 SV 1Torch start technology eliminating the electronic interference that can occur with other designs. The 1Torch provides quick, reliable starts and a strong pilot arc to pierce heavy plate. With auto-pilot restart, it can also cut expanded metal quickly and easily. The SL100 SV Torch comes with standard ATC Quick Disconnect in lengths of 25 ft (7.6 m), 35 ft (10.7 m) and 50 ft (15.2 m) Longer torch leads up to 100 ft (30.5 m) available.

Speedy 400 Laser Engraving Machine

Get Price Quote

The Speedy 400 is the new dimension in laser processing,offering maximum usability and fl exibility, with the power to increase your overall production capacity and effciency. The Speedy 400 has no front bar, which means operators have easy access to the work area. Loading and unloading bulky jobs and the optional rotary attachment has never been easier. In addition, engraving and cutting jobs can be set upquickly enabling even more ease of use for the operator.Speedy 400 is available with a CO2 laser, a fber laser or both laser sources in one laser system

Cosderma Diode Laser Hair Removal Machine

150,000 - 550,000 Per unit

1 Pack (MOQ)

Advantages of our machine 1. double security guaranty: check skin tone to unlock and no touch skin, no light. 2. Small and exquisite, easy to use, simple operation, suitable for family use. 3.save time, save money, you can enjoy it anytime any where. 4. Effective, fast, convenient and safe treatment 5.No need pain management and shorter treatment sessions 6. International hair removal golden standard. Functions 1. Hair Removal: Permanent remove unwanted hair on parts of the body , such as face, arms, back, chest, underarms, bikini line hair removal,leg, etc. 2. Rejuvenation: shrink pores,whitening skin, improve skin firmness, only suitable for light skin tone area. HOW DOES LASER HAIR REMOVAL WORK? Laser diode 808 of the semiconductor laser to produce strong, belong near-infrared light,can penetrate the hair follicle, on which the pigment is heated and spread to the entire hair follicle, precise destruction of hair follicle scan, without causing damage to adjacent tissue to achieve permanent hair removal.It emits a pulse of laser light, which heats up the dark pigment inside the hair and deactivates the hair follicle. That’s why it can deliver permanent results and works only on naturally brown or black hair. To be most effective, the MINI808 Laser needs to treat each hair follicle during its active growth period. Hair grows in cycles, so multiple treatments are necessary. FAQ How does laser hair removal work? Our laser hair removal system uses a combination of energy and heat to destroy follicles without harming the skin around them. After a series of sessions, you’ll experience permanent hair reduction. Depending which area(s) you decide to treat, you’ll always be ready to slip into a swimsuit, won’t have to think about razor burn or irritation, and will stop worrying about unsightly ingrown hairs. How long does laser hair removal take? You have millions of hair follicles in your body, all of which cycle through different phases. Laser hair removal can only treat a certain percentage of those follicles at a time (those that are in the active phase), so it must be done at varied intervals. Because no two bodies are the same, your treatment plan will be tailored specifically to you, but we typically recommend at least six laser hair removal sessions that take place four to ten weeks apart. How should I prepare for laser hair removal? With laser hair removal, nobody will know you’re undergoing treatment (unless, of course, you want them to). Laser hair removal sessions can be as short as fifteen minutes,and we just ask that you stay out of the sun, shave the area to be treated; and avoid using lotions, creams or products, for optimum results. What does laser hair removal feel like? Most clients describe the sensation as a mild “hot pinch,” similar to the feeling of being snapped with a rubber band. In most cases, the sensation goes away almost immediately.

CB1209-100 Laser Cutting Machine

Get Price Quote

Large area laser cutterproduct features this cutter relies on a imported servo motor and an enclosed structure to realize accurate movement at high speeds. This device is mainly used in wood processing, package printing, craft accessories, advertisement decoration, leather processing, clothes processing, and template production. applications & materials this cutter can be used on plastic, wood, paper, rubber, leather, chinaware, cloth, etc. technical datamax. Output laser power: 100w cutting area : 1240mm920mm max. Cutting width : 1350mm max. Cutting length : unlimited max. Cutting height : 40mm max.cutting deepth(pmma) : 15mm(8mm sec) cutting speed : 1-400mm sec orienting speed : 1-800mm sec repetition accuracy : 0.05mm focusing lens : standard 4",opt. 3" optical structure : pilot laser track movement structure : gantry structure : close electrical source : 220v 50hz 30a dimensions : 2250mm1400mm1150mm cooling system : water

Fiber Laser Marking Machine

Get Price Quote

Fiber laser cutting machine

3,000,000 Per Piece

Fiber Laser Cutting Machine is fully integrated sheet cutting machine. Fiber Laser Cutting Machine is configured with advanced hardware and software which ensures efficient and consistent performance. We offer Fiber Laser Cutting Machine in different specifications in order to meet divergent demands of the clients. Highlights Clean cutting Boosts productivity Less wastage of metals Easy operation

Bodor Laser Engraver Machine

Get Price Quote

Laser Engraving Machines

Get Price Quote

Videojet 7340 /7440 Fiber Laser Marking Machine

Get Price Quote

Laser Marking Machine

580,000 Per Piece

1 Piece(s) (MOQ)

Laser Spot Welding Machine

Get Price Quote

We make use of user-friendly interface that enables us to network and control the sorting, loading and unloading of all the finished products from a single location. By this, we make sure that the voluminous consignments are kept safely till the final send off. We are a notable name in the domain offering the best in class and quality CML-W 150 Laser Spot Welding Machine. Technology : The Principal of Laser welding machine for jewellery is thermal conduction, namely, the laser radiates the surface of the part, and the heat on the surface expands inside through heat conduction. By controlling parameters such as laser pulse width, energy, peak value and repeating frequency, the sample will melt, and thus forming specific molten pools. Due to its unique benefit, the product has been successfully applied to gold and silver jewellery processing, and welding of small-sized parts and porosity filling. Design : Personalized design for hassle free operation in compliance with ergonomics principles. Dependibility : Sturdy Frame Structure For lowest vibration makes it, ideal for factory use & trouble free operation. Display : New Touch Screen display for easy operation. Ease : Upto 10 memories cells for storing working parameters permanently. Big Inside chamber for easy movement of big samples. Advantages Fast, efficient, deep, quality welding. Welding points are free from pollution. Saves time & energy. Application for Jewellery Industry : Joining of different metals. Repairing of Precious Items with temperature sensitive area close to Diamonds & Gems stones. Assembling of jewellery parts. Holes and porosity filling. Antique repairing. Titanium spectacle frames repairing. Possible weld metals : silver, yellow and white gold, PT, Titanium.

laser welder machine

749,000 - 750,000 Per Piece

Plasma Cutting Machine

19,500 Per Set

diode laser system

Get Price Quote

Laser Marking Machines

Get Price Quote

Laser Welding Machine

Get Price Quote

Laser Hair Removal Machine

Get Price Quote

We are the main supplier of this product.

Plasma Cutting Machine

500,000 Per Piece

Laser Marking Machine

195,000 Per Piece

Die Board Laser Cutting Machine

228,800 Per Units

Plasma Cutting Machine

90,000 Per Piece

skin treatment laser machine

10,000 - 500,000 Per ex

we have all type of skin teatement laser machine, microdermabtasion with oxyjet, skin cautery & radio frequency, all type skin machine available for more details contact us

Laser Marker

Get Price Quote

Laser technology offers various methods for permanent marking and thus can be used in more diverse applications than conventional lettering methods. Whether metals, plastics, wood, or ceramics: nearly any material can be lettered, marked, or engraved permanently with a laser. advantages at a glance: · marking of different material types · high automation and speed · force-free and contact-free processing · sharp images of high quality · high design flexibility · cost reduction laser lettering can offer very good results even on rounded surfaces, and can be performed even on moving components (“marking on the fly”). Laser lettering can be generated quickly automatically and individually. Using this process, computer-aided control provides a large degree of flexibility for the form and content of the lettering. 1: scanner 2: objective 3: laser beam 4: work piece 5: marking alphanumeric characters, graphics, logos, barcodes, etc. Can be applied to components. Accordingly, laser lettering systems are used widely in the production of consumer goods and industrial products, in the automobile industry, machinery and plant assembly, and even for tool manufacture. Permanent signatures are guaranteed even under the effect of vapor, oils, emulsions, and other fluids. Extensive software packages equipped with graphics-based user interfaces are used for control of the laser system. They make it possible to create texts, fill objects, insert pictures, create serial numbers, and display movements of the scanner.

laser soldering machine

595,000 Per Piece

1 Piece(s) (MOQ)

digital photocopier machine

Get Price Quote

Plasma Cutting Machine

Get Price Quote

Skin Analysis Machine

Get Price Quote

1 Piece(s) (MOQ)

Laser Engraving Machines

Get Price Quote

Add print provides new technology laser cutting and engraving machines useful for cutting and engraving. To know more about this product click the link given below.