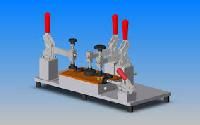

Perfume Crimped Bottle Leak Testing Machine

50,000 Per Piece

1 Piece (MOQ)

Surge Arrestor Leakage Current Analyzer

Get Price Quote

Best Deals from Leak Testing Machine

Bottle Leak Testing Machine

Get Price Quote

Perfume Leak Testing Machine

Get Price Quote

Machine Applications Leak Testing Of Perfume Bottles Leak Testing Of Glass Bottles Leak Testing Of Crimped Bottles

Leakage Current Tester

Get Price Quote

Leakage Current Tester Test to measure the undesirable leakage current that flows through or across the surface of the insulation or the dielectric of a capacitor . Features Accurately designed current measuring system Both live and neutral polarity test can be performed Reset facility after tripping Flexible models w r t leakage current, test voltage, online / offline testing

Circoflux Magnetic Flux Leakage Testing Solution

Get Price Quote

1 Piece (MOQ)

NON-DESTRUCTIVE CRACK TESTING WITH ROTATING PROBE The CIRCOFLUX test system is used for the non-destructive surface testing of ferromagnetic steel bars using the magnetic flux leakage method in accordance with standard EN 10221. This method is the most sensitive surface testing method for longitudinal, crack-like defects in hot-rolled ferromagnetic steel bars. The CIRCOFLUX sensor system therefore replaces subjective testing methods such as the magnetic powder test (magnetic crack detection) and visual checks, which are difficult to document and reproduce. The available sensor systems cover a material diameter range from approx. 10 to 180 mm. FOERSTER''s long-standing experience in this field ensures high operating reliability. The modular design of the test electronics is also ideally suited to meet future demand for ever increasing defect detection sensitivity. Your advantages at a glance Standardized hardware and software for all FOERSTER test instruments simplifies the handling Easy operation using modern touchscreen display Network integration in existing production and quality systems Integrated diagnostic and documentation function for compiling your test results Relational database for high data integrity and open port to other applications Maximum detection sensitivity of defects from 0.1 mm depth on ferromagnetic rods with hot-rolled surface Test material diameter from 10 - 180 mm Pivoting test levers also tolerate non-straight material and protect against damage to or destruction of the test elements Central adjustment to the test diameter minimizes the risk of adjustment errors Automatic dimensions adjustment reduces setting up time and increases productivity Technical Data Sensor system: Rotating sensor system with two opposite test heads Max. number of measurement channels: 24 Max. throughput speed: 4 m/s Magnetizing current frequency: 6 kHz (Ro75, Ro100, Ro180) or 7.5 kHz (Ro130) Testing error: depth 0.15 mm x width 0.1 mm Diameter ranges: 10 - 75 mm (Ro 75); 10 - 100 mm and 15 - 105 mm (Ro 100); 15 - 130 mm (Ro 130); 20 - 180 mm (Ro 180) Setting time (with roller guide): approx. 3 minutes (Ro 75, Ro 100, Ro 130); approx. 5 minutes (Ro 180) Maximum rotational speeds: 2,400 rpm (Ro 75); 1,500 rpm (Ro 100 and Ro 130); 960 rpm (Ro 180) Maximum throughput speed: 2 m/s (Ro 75); 3.75 m/s (Ro 100); 4 m/s (Ro 130); 2.4 m/s (Ro 180)

leak locator

Get Price Quote

leak testing equipment

Get Price Quote

Description :-Leak testing equipment refers to a class of nondestructive testing equipment commonly used to measure the escape of liquids, vacuum or gases from sealed components or systems. There are some arrangement of leak testing equipment that require a separate sensor or leak detector as an input. These devices are often equipped with various other components such as calibrators, gauges, pumps and cases.Application :These equipment find a wide application in the following areas: Research & Development System Manufacturing Furnace/Metallurgy Refrigeration Manufacturing Air Conditioning Manufacturing Chemical Industry Analytical Requirements Automotive Component Industry Oil & Gas Plants

Current Leakage Testers

Get Price Quote

Description :-Current leakage testers are devices that are used to measure the amount of current that passes through a ground conductor. These devices can be used both during normal and single-fault conditions to determine whether electrical devices pose a shock hazard.Salient Features & Uses :These equipment find a wide application in the following areas: The tester consists of a measuring device or probe that gets connected to a voltmeter that displays root mean square values. The tester also includes a circuit featuring specific frequency and resistance. Available as manual, semi-automatic and automatic types. Common testers include an RS232 serial bus or a parallel port designed for connecting to a printer. There are some leakage testers, which consists of a general-purpose interface bus and are designed to connect to computers, peripherals, and laboratory instruments. These devices differ in terms of current leakage range, communications, resistance range and special features. The leakage testers meet the requirements of various national and international standard organizations. Provided with a rapid cut off system to protect the device from high voltage or current. Provided with front panel lockouts that prevent any damage to the instrument during testing.

Leak Testing Fixture

Get Price Quote

Leak Testing Fixture, Duplex dies, precision fixtures

Leak Testing Fixture

Get Price Quote

Leak Testing Fixture, Pultrusion Dies, precision jig