torch height controller

Get Price Quote

Features PTHC-200DC is our new stand alone THC in 2013, comparing to old XPTHCs, it has new features as follow :- Support Torch retaining cap IHS or Nozzle Contact (ohmic contact) IHS with any HF plasma…..Great anti-interference improvement. PTHC has much higher accuracy than old XPTHCs, standard accuracy is 1V, enough to support HD plasmas. max support 12000mm/min cutting speed. Support Dynamic pierce, collision output to CNC. Key Features Auto Initial Height Sensing(IHS) Torch Retaining Cap IHS( ohmic contact) and Proximity Switch IHS both available, Proximity Switch IHS is for cutting dirty/rusty workpiece, needing the Anti-Collision Fixture designed by HYD (breakaway kit ). It supports underwater cutting,too. Anti-Collision Function When torch tip touches workpiece, THC automatically lift torch up to IHS height to avoid crashing. It is effective both on Manual/Auto mode. Freeze Auto Height Control on Corner Signal XPTHC-300 would freeze Auto Mode on receiving corner signal from CNC system to avoid torch diving on Cycle start/end, corner turning. Support DC/AC24V powersupply both Dual speed during IHS, better torch tip protection, and 6 indicators to easy trouble-shooting. When it get problem, we can easily find the problem by the indicator's on/off state and make fast solution to customer. THC sensitivity, torch retract height after cutting....many functions adjustable to user.

Automatic Torch Height Control

Get Price Quote

Best Deals from Limit Controller

PID-480 Controller

Get Price Quote

Features : Microcontroller based Design Software linearized for better measurement accuracy Field proven PID algorithm Works on universal 90-240VAC Universal and User selectable input from process transmitters/temperature sensors 1 to 4 Relay or SSR or 4-20mA/0-5V/0-10V control Output Industrial standard Analog and Digital Interface

Pid Temperature Controller

Get Price Quote

Wall Mount pH Differential Controller

Get Price Quote

Built-in non-volatile memory to ensure that calibration and other information are not erased if power supply fails. :: Menu-driven program that simplifies set-up. :: Automatic temperature compensation (ATC) :: Manual temperature compensation setting without the ATC probe, with independent setting for calibration and process temperature. :: Two galvanically isolated current outputs 04...20mA. :: Two switching contacts as set-point relays. :: 0 to 2000 seconds time delay adjustment on all relays – minimizes false alarms :: Separately adjustable high and low set-point hysteresis (dead bands) prevent chattering of relays around the set points. :: Three control modes: limit controller, P controller and PI controller (PPI controller as pulse length or pulse frequency). :: Large dual display LCD for easy reading with clear multiple annunciators, alarm status, operational and error messages. :: Separate alarm relay that alerts user to set point limits exceeded for a certain time and if the NTC300 thermistor wires are broken or disconnected during the ATC function

Digital PID Temperature Controller

Get Price Quote

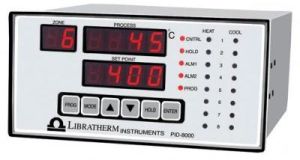

Libratherm offers Microprocessor based one to eight loop PID Temperature Controller (Model PID- 8000) for processes requiring multiple zones heating or heating plus cooling control. It is most suitable for difficult process, which results in frequent system disturbances, and applications where simultaneous and accurate temperature control of number of heatingcooling zone is required. It also eliminates the need for number of individual PID or ONOFF Temperature Controllers thereby saves on cost. PID-8000 can accept 8 similar type of Thermocouples or RTD (Pt-100) inputs and can provide switching PID or ONOFF Control output in the form of DC Pulses or SSR Drivers for heating and cooling. It can also simultaneously provide 8 analog PID control Outputs in the form of (4-20mA) or (0-5) volt, which can be used to drive external SCR Heater Power Controller or other actuators. Open or Faulty sensor indications for each zone is also displayed with the respective Zone No. Each zone loop parameters like PID, SET, Hysterisis, Power Limit and Ramp Time values can be independently programmed from the user-friendly front panel membrane keyboard. Features: Microprocessor based design. Elegant looks and Very easy to operate. Accepts all types of maximum 8 inputs. PID or ON Off heat and cool action per channel. All zones are individually configurable for Heat or Cool. Compact in size – ½ DIN (192 x 96 x 200 mm).

Multi Loop PID Controller

Get Price Quote

Libratherm offers Microprocessor based Eight Zone PID Temperature Controller (Model PID-8000) (AS GOOD AS EIGHT PID CONTROLLERS IN A SINGLE UNIT) for processes requiring multiple zone heating or heating plus cooling control. It is most suitable for difficult processes which results in frequent system disturbances, and applications where accurate and simultaneous temperature control of number of heatingcooling zone is required. It also eliminates the need for number of individual PID or ONOFF Temperature Controllers thereby saves on cost and panel space. It can accept 8 Thermocouples or RTD (Pt-100) Inputs and can provide switching PID or ONOFF Control output in the form of DC Pulses or SSR Drivers for heating and cooling. It can also simultaneously provide 8 analog PID control Outputs in the form of (4-20mA) or (0-5) volt, which can be used to drive external SCR Heater Power Controller or other actuators. Open or Faulty sensor indications for each zone is also displayed with the respective Zone No. Each zone loop parameters like PID, SET, Hysterisis , Power Limit and Ramp Time values can be programmed from the user-friendly front panel membrane keyboard. The display scan rate is programmable from 1 to 99 seconds, whereas the internal control scanning is at the rate of 100mS. It also provides common High and Low alarm relay outputs which can be used for external temperature dependent inter locking or audiovisual alarm.PID-8000 is available in standard 12 DIN (192 x 96 x 200mm) for 8 zones, 6 zones or 4 zones. It operates on 230 VAC with built in high and low supply voltage trip circuits. It is also protected against industrial RFIEMI Interference. Libratherm also supplies complete Multizone Temperature Control Panel, which finds its applications in Plastic Extruders, Plastic Injection, Tunnel Furnaces, Ovens etc.ApplicationPlastic extrudersHeat treatmentRubber industryFurnace Oven controlFood processingEnvironmental chambersMulti zone furnaceMetal industryCold Storage and Chilling plantsLaboratory equipment etc.

torch height controller

Get Price Quote

Specifications Accurate control of Torch to work distance be it Cutting of Welding, plays very important role for the quality of the end result Torch Height Controller (THC) is also known as Arc Voltage Controller (AVC) it is the device which maintains the arc gap between the torch & the work piece. Stepper motor driven vertical slide with motor driver & the controller allows the torch to move up or down depending upon the parameters set. Arc voltage which acts as a Feedback to the controller as reference voltage, allows operator to set the Torch to Job gap as per the process & the quality requirement. Arcraft Plasma has introduced Digital model DigiTHC100 Features of the DigiTHC100 are.......... Suitable for welding processes like TIG, Plasma welding, PTA or Powder plasma welding. Suitable for Plasma Arc cutting. Wide range of Arc voltage acceptability. Well protected from the High Frequency interference. Piercing program for plasma cutting. Programmability in terms of Arc Voltage or Arc Gap distance. Independently adaptable to any Plasma cutting or Welding power source Independently adaptable to CNC profile cutting machine. Independently adaptable to Welding Automation. Initial Height Sensing (IHS) comes in handy to pre-adjust the required gap before start of process. Advantages of DigiTHC100 Plasma Cutting Improvement in cut quality Improvement in consumable life upto 20% High productivity at high dimensional accuracy of cut components. Elimination of near collision condition of Torch & job. Welding Uniformity of weld beads Controlled weld heat input eliminates chances of higher percentage of dilution, lack of penetration, undercut etc. Easy adjustment of weld pool fluidity depending upon the application of weld & welding process by maintaining the constant gap & hence the heat input. Dramatic improvement in weld aesthetics.

Alpha pH1000 ORP Controller

Get Price Quote

Built-In Programmable Limit, Proportional (Pulse Length or Pulse Frequency) - ideal for precision process control applications :: User-Customization through Advanced Setup Menu offers flexibility in matching the controllers functions to suit individuals specific requirement :: Automatic Calibration with Auto-Buffer Recognition eliminates mistakes during calibration :: Symmetrical Mode Operation eliminates electronic noise problems when used with solution ground :: One-Point Online Calibration without shutting down the line :: Hold Relay for use with float switchesflow switches and other controllers as a failsafe function :: Two Level Password Protection prevents un authorized tampering with settings :: 0 to 2000 Second Time Delay Adjustment on control and alarm delays :: Galvanically Isolated Scaleable 0-204-20 mA Outputs for pHORP :: Wash Contact Relay controls electrodes cleaning systems at desired duration and frequency :: Choice of Glass or Antimony Electrode for general purpose or hydrofluoric acid applications :: Adjustable Hysteresis (Dead Band) prevents rapid contact switching near set point :: Non-Volatile Memory retains all stored parameters and calibration data even if power fails

Speed Dome Camera Controller

Get Price Quote

Speed Dome Camera Controller, Burglar Alarm Systems, speed dome

pH Controller

Get Price Quote

pH Controller, Temperature Controller

controllers

Get Price Quote

controllers, TEMPERATURE, humidity scanners, Lux Meter

Maximum Demand Controller

Get Price Quote

Maximum Demand Controller, Automatic Power Factor Controller, Power Monitor

Maximum Demand Controller

Get Price Quote

Maximum Demand Controller, Automatic Power Factor Controller, Power Monitor

Programmable PID Temperature Controller

Get Price Quote

Programmable PID Temperature Controller, Oven Temperature Indicator

Demand Controller

Get Price Quote

Demand Controller, EMS Software, Demand Monitor, multi- function meters

PID CONTROLLER

Get Price Quote

PID CONTROLLER, gi sheets, Switch Gears, Polycab Wire cables

PID CONTROLLER

Get Price Quote

PID CONTROLLER, Digital Temperature Controller, Temperature Controller

Humidity Controller

Get Price Quote

electronic process control instrument, Temperature Controllers

controllers

Get Price Quote

controllers, Engineering Goods, RPM Indicators, Stepper Motor Drive