Rotary Perfume Filling Machine

Get Price Quote

ONE Piece(s) (MOQ)

Automatic 9 Head Rotary Perfume Filling MC (with Vaccumetric type) providing with product Transfer Pump. This is the simple MC with various types & shapes of Glass Bottles to be fill after keep the bottles Manually onto the Rotary discplatform. This is the height adjustable type MC with easy setting operational work for different height of bottles to be use. Such type of MC getting Output 35 Bottlesmin Max speed for 100 ml Fill quantity & accordingly increase the speed if Volume is Less than 100 ml. All contact Parts will be SS 316 with PTFE (wherever applicable) & rest of the non contact parts will be SS 304. This is the simple operation to fill the perfume by vaccumetric; during the filling excess volume will be return automatically at the storage Glass flask (which is mounted on Top side of the Filler). For this MC will providing FLP Motor along with VFD for requirement of speed control during the Filling operational work. Will be keeping the provision for providing SS Packing conveyor for further Manually Pump Lading & Crimping as well as Collar Pressing operational work. SS Control Panel providing with VFD to Main MC drive arrangement & for the Vaccum Pump arrangement.

Automatic Liquid Filling Machine

Get Price Quote

Our Fully automatic liquid filling and capping is capable of filling liquids of different viscosities and sealing bottles accurately in one stroke. These machines are robust in structure and require minimum maintenance. By using this machines manufacturer can minimize the chance of foreign particles in the bottles, as there is no travel of bottles between filling and sealing.

Best Deals from Liquid Filling Machinery

Liquid Filling Machine

Get Price Quote

Global Pack machinery Liquid Filler Machine which designed with motor driven mechanism. .It offers Liquid Filler machine in different ranges from 5 ml to 1000 ml filling. The high level of accuracy meets the quality control specifications of the industry while the system is able to keep up with required production speeds. Speeds and accuracy have been combined in one machine Specification: The Global" series of Liquid Filling Machine can be used for dispensing: Milk Buttermilk Edible oil Industrial oil Pharmaceutical liquid and many other liquid products SALIENT FEATURES Built in mild steel body with all other contacted parts are in stainless steel sheet Compact, versatile and elegantly mat finished unit Accuracy of filling +- 1% throughout the operation Ideal for filling in bottles, cans , tins etc Single or twin heads volumetric filling system Any liquid or semi- liquid products can be filled Stainless steel pump with adjustable and suitable piston rings for easy cleaning of entire pump set. ALSO KNOWN ASS Filler machine for cans -Volumetric liquid filler machine Liquid piston filler -Semi automatic liquid filler machine

Vaccumetric 9 Head Rotary Perfume Filling Machine

750,000 Per Piece

1 Piece (MOQ)

Linear Counter Pressure Filler

Get Price Quote

liquid filling machines

Get Price Quote

As a trusted Liquid Filling Machine Manufacturer, exporter and supplier we offer an advanced range that can be availed in a wide variety. The complete range is designed by experts to match international standards and manufactured using the precision components and other materials. Known for delivering superior performance, the Liquid Filling Machines offered by us are tested on various parameters to assure hassle-free operation together with a long functional life.

Piston Filling Machine

Get Price Quote

in these applications, the filling machine might be classed as a positive-displacement filling machine instead of a volumetric filling machine. These machines are manufactured with single or multiple filling heads, and they can be used manual as well as automatic operations. Each machine is also equipped with an adjustable piston stroke to permit a single unit to fill variable amounts of product. During operation, product is drawn into the piston cylinder head. As the piston reverses its travel, the product is discharged from the cylinder into the container. If it is mechanical then the piston is driven by an eccentric crank connected to the driven shaft of the motor or speed reducer. The crank or piston rod is slotted to allow the piston stroke to be adjusted as required. A filled container can then be moved along manually or integrated with conveyor. These processes can be repeated cycles can be performed to fill volumes that are higher than the cylinder capacity. Our volumetric piston fillers are used by industries in the food & beverage, cosmetics, and personal care, agricultural, animal care, pharmaceutical, and chemical fields.

Two Head Piston Filling Machine

Get Price Quote

We are a reputed Manufacturer, Exporter and Supplier of Two Head Piston Filling Machine, which is designed as per the set industry standards. The Two Head Piston Filling Machine is highly appreciated for its superior performance and longer working life. Further, we offer Two Head Piston Filling Machine at market leading prices. Specifications Motorised or pneumatically operatedFilling range available from 5ml to 5ltrs in different machineIn pneumatic model complete microprocessor based systemAll Contact parts in stainless steel 304/316 quality Used For Filling Products Such As OilPaintVarnishThinnerInkMilkChemicalsLubricantsAdhesive

Package Drinking Water Machine

Get Price Quote

The Filling valves work on the gravity principle, the water is supplied to the filling bowl by a centrifugal pump, and the water level in the tank is controlled. The bottles are raised to the filling nozzle by positive lift cylinder, if the bottle is not delivered the valve does not open. The water will be filled to pre set level and the bottle is lowered. The lift cylinders operate on positive cam lift-off principle and do not use compressed air or spring load. Lift cylinder cam is made of stainless steel and machined to fine finish and have simple harmonic motion profile to lift bottles smoothly to filling valve. The filling valve works on gravity filling system but has AIR EXHAUST system which removes stagnant air from the bottle to outside atmosphere and do not allow bottle air to mix with ozone atmosphere in filler bowl. The top of the filling bowl/tank is fitted with central manifold to connect all filling valves to single line vent pipe, which can be piped to outside of the filling room. To the same vent pipe reverse flow CIP liquid is connected by isolation butterfly valve. The filling bowl is fitted with Electro-Magnetic type level controller to regulate water level in the bowl through pneumatic ON-OFF valve.

Semi Automatic Roll On Perfume Filling Plug Pushing Capping Machine

Get Price Quote

This machine is suitable for filling-plug pressing-capping of roll-on perfume bottles. Application: Roll on perfume filling machine is suitable for filling 5ml-100ml sizes of bottles.The design and configuration of this machine, which controlled with PLC, are compact and reasonable. Vacuum filling systems draw product into the container by using constant vacuum suction. When the product reaches the vacuum port, the excess product is drawn back into the collecting bottles. The fill level of the container is determined by the depth of the vacuum port within the neck of the container. Therefore the fill level will be the same regardless of the inconsistencies of the containers. The material of the collecting bottles is pharmaceutical grade, and the product in the bottles can be recycled. The number of the filling nozzles and the length of the conveyors can be custom-made according to your special requirement.

automatic vial liquid filling machine

Get Price Quote

If you are searching for high quality Automatic Vial Filling, then you are the perfect destination for you. We present Automatic Liquid Vial Filling Machine that is designed to meet sealing applications in pharmaceutical industries. Used for sealing pharma products, Automatic Liquid Vial Filling Machine is highly demanded in the market. Some of the features due to which Automatic Liquid Vial Filling Machine is widely appreciated are high performance, maximum durability and easy operation. Besides this, we provide availability of Automatic Liquid Vial Filling Machine at the most reasonable prices. We are named as one of the leading Vial Filling Stoppering Machine Exporters from India. COMBINE AUTOMATIC VIAL FILLING AND RUBBER STOPPERING MACHINE SEALING MACHINE GMP MODEL FFS-80 FABRICA Combine Automatic Vial Filling and Rubber Stoppering Machine cGMP Model : FFS-80 is a very compact, comprehensive and elegantly finished cGMP designer Machine. The machine provides overall economy by reducing space, length of laminar flow and number of personnel in sterile area. Salient Features : Unit is rigid, vibration free construction for trouble free performanceNo Vial, No Fill systems saves valuable liquid and downtime for cleaningNo container, No stopper system is observedSpecial safety device to prevent damage to working partsCompact Line Saves space utilisation, reduces length of laminar flow and number of personnel in sterile areaObserving true GMPAll contact parts can easily be removed for mandatory requirement of sterilizationUnique pressing head ensures No Popping Off of stoppers

Mechanical Piston Filling Machine

Get Price Quote

We are offering mechanical piston filling machine. Our mechanical piston filling machines are precisely designed to meet the specific requirements of the clients in most satisfactory manner. The robust construction and long operational life have made them hugely popular among clients.

Vacuumetric Perfume Filling Machine

Get Price Quote

1 Piece(s) (MOQ)

liquid filling machineries

Get Price Quote

liquid filling machineries, cosmetics machineries, cream plant machineries

Beverage Vending Machine

Get Price Quote

We are among the leading manufacturers and exporters of mineral water vending machines .Our range of vending machines is very popular amongst our clients across the globe. These machines are installed in cafeterias, canteens, government and private organizations.

Water Pouch Packing Machine

Get Price Quote

We are leading water pouch packing machine manufacturers providing this is fully automatic water packing machine designed for packing liquid in LDPE film, commonly known as milk packing machine. The film roll mounted on backside of machine, after unwinding mechanism film passes through series of free roller. Film will be folded in folding collar box to get shape of pouch, center sealing will be by vertical impulse strip sealer. Pulling and pouch length of the machine depends on rubber roller pulling assembly driven by eccentric cam which is adjustable.

Mineral Water Filling Sealing Machine

Get Price Quote

Model No. CNR2 Two Head in this Machine. This Machine is conveyor type cup filling & sealing Machine. This Machine is pneumatic cum mechanical working RINSING FACILITY AVAILABLE IN THIS MACHINE Cup manual keep (Empty) and after sealing pickup by hand Feature -• Easy to operate • Easy to maintain • Rinsing Available Temperature Controller 0 to 4000C (2 Nos.) Filling Timer 2 Nos. Products Contact Parts S. S. 304 Machine Dimension L x W x H 1905 x 515 x 915mm Worm Reduction Gear Box Vacuum 1/2" Application -• Mineral water • Curd • Yoghurt • Lassi • Juice • Non Viscous Products

Vial Filling Machine

Get Price Quote

1 Piece (MOQ)

Automatic Liquid Filling Machine

Get Price Quote

Cold Drink Vending Machine

Get Price Quote

We are identified as one of the most celebrated Drink Vending Machines Exporters and Suppliers in India. The materials used in the manufacturing of the Cold Drink Vending Machine are of optimum quality that ensures notable features like high durability, strength, low power consumption etc. Various national as well as international clients are placing bulk orders for the Drink Vending Machines due to the unmatched quality and unsurpassable performance in respective applications. The below mentioned salient features have also played a crucial role in the enhancement of the demand of the Cold Drink Vending Machines in the global market. Salient Features: Multiple selections through host. Machine and glass front for maximum sales impact. Designed for Cans, PET bottles and Tetra - packs. Transaction through Bill (Notes) Acceptor, Coin Changer, Smart Card reader and Mobile Phones Operated Readers on Host machine. Simple Plug in with Host Machine. 24 V DC Motorized Vending Mechanism. Digital MIS Display. Adjustable Tray Partition and Height. Product Vend Sensor (Optional). Fast and Easy Product Loading. Low Maintenance.

Piston Filling Machine

Get Price Quote

the filling machine might be classed as a positive-displacement filling machine instead of a volumetric filling machine. These machines are manufactured with single or multiple filling heads, and they can be used manual as well as automatic operations. Each machine is also equipped with an adjustable piston stroke to permit a single unit to fill variable amounts of product.During operation, product is drawn into the piston cylinder head. As the piston reverses its travel, liquid product is discharged from the cylinder to into the container. If it is mechanical then the piston is driven by an eccentric crank connected to the driven shaft of the motor or speed reducer. The crank or piston rod is slotted to allow the piston stroke to be adjusted as required.

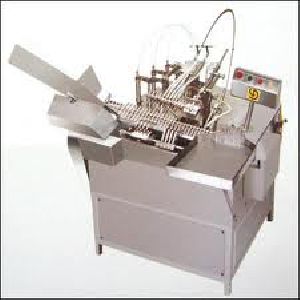

Automatic Ampoule Filling & Sealing Machine

Get Price Quote

Automatic Ampoule Filling & Sealing Machine The machine built on principle of slant travel of ampoules while filling & sealing. To Take care of vide variation of ampoule neck dimensions, thickness and ovality of available Indian ampoules. The unit on SS square pipe frame and totally encompassed with SS coverings. In pleasing matt finished further. The large opening available at the bottom side for easy of absolute cleaning The pendant type electrical control panel is lifted frp, machine for ease of operation and safety.

Piston Filling Machine

Get Price Quote

The Volumetric Liquid Filling Systems are designed for completely automatic, multiple position, in-line dispensing of liquids and pastes in volumes ranging from 5 ml to 5 litters per cycle. Available in 2, 4, 6, or 8 nozzle configurations to match specific production requirements. Dual lane option available to increase production by 100% while preserving valuable line space. Precision bored, heavy-walled metering cylinders dispense product at accuracies up to +- 0.25%. All product contact parts constructed of stainless steelfood grade plastics for sanitary operations or use with corrosive materials. Available with motorized conveyor and indexing package for integrated container handling and positioning. No Container-No Fill feature detects missing or dispositional containers to prevent waste and product spillage. Unique variable, separate speed control and actuator of a dual-stage fill provides precise “no spill” control for top-off applications or filling difficult products. Versatile Programmable Logic Controller (PLC) ensures reliable, repeatable control with minimal operator intervention.

Volumetric Liquid Filling Machine

Get Price Quote

Liquid filling machine is designed to continuously fill various liquids such as syrups, oils, liquid soaps, beverages etc. It is very compact and occupies very little space. Our client can also avail a vast range of Volumetric Liquid Filling Machine widely used for filling various free-flowing granular products like tea, sugar, salt, pulses, and grains. The combination of high-end technologies and quality raw material has contributed in the durable, safe, easy and reliable operation of these fillers. These Semi Automatic Volumetric Liquid Filling Machines are manufactured from high grade quality material and are easily available at very reasonable price in market. These machines are suitable for round or flat shape bottles or vials. Our machines have output of maximum 20 Products per minute depending on nature of liquids, neck diameter or vial/bottle and fill volume. The range is available in different models and specifications. Along with standard range , we offer customized versions to suit specific requirements. High technology ensures easy operations and installation. Maintenance free, user friendly operations and high efficiency are some of the features because of which these are highly demanded in national as well as international markets.

Volumetric Liquid Filling Machine

Get Price Quote

Volumetric Liquid Filling Machine, capsule section machine

Perfume Head Filling Machines

Get Price Quote

Perfume Head Filling Machines, punching die, Ointment Manufacturing Vessel

Soft Drinks Making Machinery

Get Price Quote

Soft Drinks Making Machinery, Mineral Water Machinery

Vial Filling Machine

Get Price Quote

Vial Filling Machine, Ampoule Filling Machine, Vial Sealing Machine

Perfume Filling Machines

Get Price Quote

Perfume Filling Machines, Machinery Spare Parts

beverages vending machines

Get Price Quote

Features : All Stainless Steel Cabinet No thermostat Easy, hassle-free Operations Facility for full & half cup Auto cleaning system Hot water facility Digital systems with Temperature lock Digital setting of Powder & water Quantity Digital display of Temperature & Cuppage counts Coin Biometrics Smart Card Mechanism Analog version also available Low power Consumption