Z-TYPE ELEVATOR

Z type elevators are useful for delicately conveying granular products under most hygienic conditions. The overlapping buckets designed ensures no spillage, whereas the specially designed food grade PP buckets eliminates the chances of product contamination. The modular structure of the elevator ensures a high degree of flexibility regarding conveying to horizontal and vertical distances. The drive unit comprises of rugged chain and sprocket mechanism. The buckets are mounted on extended pins on the chains.

...more

Vibratory Feeder

This comprises of horizontal tray mounted fibre glass strips to ensure flexible linear motion. The vibration to the tray is given by an electromagnetic coil mounted below it. Due to the high frequency linear vibration of the tray, material gradually moves the material from the hopper into the tray and discharges at the other end.

...more

ULTRA-FINE MILL

This is screenless pulveriser used for grinding soft to medium hard materials into super fine powder. The machine has built-in water jacket to keep down the temperature in machine chamber. This machine is generally used for superfine grinding of food dyes, industrial dye intermediated, pharmaceuticals drugs, chemicals, etc. The feed is through the feeder screw that feeds material into machine chamber.The grinding takes place due to attrition between a high-speed rotating rotor having six wear resistant tips and side liners on both sides of the tips and also a turbo effect. The annular gap plate controls the flow of materials through the mill. In other words, it regulated the fineness of the material. The powder is discharged through the bottom hopper.

...more

Tray Dryer

Tray drier is an Insulated Chamber within which hot air is on continuously circulated. Forced convection heating takes place to remove moisture from the solids placed in trays.Trolleys containing trays are dragged inside the drier. Electrical heating elements are used to generate heat inside the drier.

...more

sieve separator

Gyro Vibratory Sieve Separator are self-constrained, compact, production machineswhich make precise mechanical separations according to particle size throughefficient use of multiplane inertial vibrations techniques. They are designed andbuilt to solve the most difficult classifying, separating and dewatering problems. Material to be screened is fed to the top screen. Oversize particles are moved by themultiplane motion to the screen periphery where it gets discharged. Undersizeparticle or liquid passes rapidly through the screen. Gyro Sieve Separators areequipped to handle upto three screens. The 3 dimensional inertial vibration of Gyro Vibratory Sieve Separator is based on aprinciple in which motor rotation imparts vibration to the entire screen assembly inboth vertical and horizontal planes.

...more

SCREW FEEDER

It comprises of a spiral flights fixed on a rod enclose in a pipe driven by a geared drive unit. The speed can be varied by Variable Frequency Drive. Material is received from feed hopper at the inlet at one end and discharged into the subsequent at the other end.

...more

Ribbon Blender

The Ribbon Blender uniformly blends different spices / materials. The dimensionsand configuration of the ribbons are carefully balanced to provide a movement ofmaterial within the blender that avoids dead spots and gives rapid productdischarge. The outer ribbon moves the material from ends to the centre while the innerribbon moves it from centre to the ends this cross movements allowshomogeneous and a perfect blend. It is manufactured in Stainless Steel Contact parts.Note: Models above FRB-250 are ‘no load start’

...more

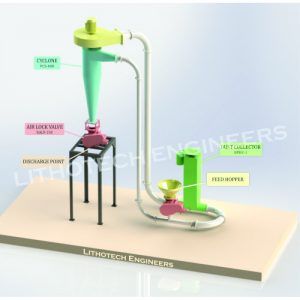

Pneumatic Conveying Systems

The Pneumatic Conveying system will convey the powder from the Pulveriser into the collection bin. It will separate the air from the material thereby preventing dusting. The air will exit through the Dust Collector. The constant circulation of fresh Air into the system ensures powder to remain cool.

...more

Pin Mill

This machine is used for very soft materials like sugar, salts, chemicals, dyestuffs, etc for medium fine to fine grinding. This material is centrally fed into the machine chamber. The grinding takes place between a high speed rotor consisting of a large number of pins and a stationary stator. The discharge takes place through the perforated screen throughout the periphery.

...more

Impex Mill Impact Pulverizer

Impex Mill is a screenless pulverizer suitable for grinding hard and brittle materialslike turmeric, minerals, etc. to a fineness of 100 to 300 Mesh BSS. It is done bycontinuous impact of rotating hammers against grinding liners. The raw material isfed into the rotary feeder from inlet hopper and spills into the grinding chamber.Strong hammering action breaks lumps into small particles. At the same time theblower sucks the air towards the whizzer classifier. Whizzer classifier doesn’t allowoversize particles to pass and returns it into the grinding chamber, where afterregrinding the desired fineness is achieved.

...more

Hammer Mill

The most versatile machine that is used to grind almost all materials like spices, foodstuffs, chemicals, ayurvedic herbals, minerals and other miscellaneous materials. The grinding takes place between the high-speed swinging hammers and top/side liners. Once the particle size reduces to that of the perforated screen at the bottom, it will be discharged through the hopper. The fineness of the material can be controlled by changing the speed of the rotor(hammer), content of serrations on liners number of hammers and diameter of perforation on the screen.

...more

Food Chopper

Chopper has been specially designed for granulating & cutting various materials like foodstuffs, agro,ayurvedic herbs, etc. into small pieces of required size with minimum of powder content. There is no heat generation while grinding thereby retaining important properties like aroma taste flavour and colour. Some typical application are making crushed chillies for pizza toppings,chopped / minced / granulated onions, tea-cut herbal products, granulating of food colours, gum, asafoetida, crushing of various ayurvedic herbs for Extraction purpose, etc.

...more

DUMP BOOTH

This equipment ensures proper feeding mechanism with controlled feed rate and dust free atmosphere. Raw materials which are normally in gunny bags are emptied on the grid inside the dump booth. Around 3 bags can be unloaded simultaneously. There is a hood above which is connected to the suction line would collect the dust generated during emptying the bags. The material slides in the screw conveyor mounted below it which conveys the materials at uniform feed rate. The speed is controlled through VFD depending upon the application. The simultaneous feeding of different spices ensures blending prior to grinding. This reduces the blending time during final blending operation.

...moreBe first to Rate

Rate ThisOpening Hours