Ultrafine Mill

160,000 Per Set

1 Set (MOQ)

We are manufacturing and exporting Grinding Mill from Vasai, Maharashtra, India. This is a screenless pulveriser used for grinding soft to medium hard materials into super-fine powder. The industrial grinding machine has a built-in water jacket to keep down the temperature in the machine chamber. This is a screenless pulveriser used for grinding so to medium hard materials into super fine powder. The machine have built-in water jacket to keep down the temperature in the machine chamber. This machine is generally used for superfine grinding of food dyes, industrial dye intermediates, pharmaceucals drugs, chemicals, etc. The feed is through the feeder screw that feeds material centrally into the machine chamber. The grinding takes place due to arion between a high speed rotang rotor having six wear resistant ps and side liners on both side of the ps and also a turbo effect. The annular gap plate controls the flow of materials through the mill. In other words it regulates the fineness of the material. The powder is discharged through the boom hopper.

Country of Origin : India

Voltage : 220V

Color : Light Green

Driven Type : Electric

Material : Mild Steel

...more

Turmeric Grinding Impex Mill

155,000 Per Piece

Impex Pulverizer is one among the wide range of Industrial Crushers that is designed for medium fine grinding of soft or semi hard materials Impex Pulverizer is a screenless pulverizer suitable for grinding hard and brile materials like turmeric, minerals, etc. to a fineness of 100 to 300 Mesh BSS. It is done by connuous impact of rotang hammers against grinding liners. The raw material is fed into the rotary feeder from inlet hopper and spills into the grinding chamber. Strong hammering acon breaks lumps into small parcles. At the same me the blower sucks the air towards the whizzer classifier. Whizzer classifier doesn't allow oversize parcles to pass and returns it into the grinding chamber, where aer regrinding the desired fineness is achieved.

Voltage : 440V

Power : 10-160kW

Color : Grey

...more

Tray Dryer

220,000 Per piece

1 piece (MOQ)

We are a preferable exporter, manufacturer of Tray Dryer in Vasai, Maharashtra, India. Tray dryer is an Insulated Chamber within which hot air is on continuously circulated. Forced convection heating takes place to remove moisture from the solids placed in trays.Trolleys containing trays are dragged inside the dryer. Electrical heating elements are used to generate heat inside the dryer. Tray drier is an Insulated Chamber within which hot air is connuously circulated. Forced convecon heang takes place to remove moisture from the solids placed in trays. Trolleys containing trays are dragged inside the drier. Electrical heang elements are used to generate heat inside the drier.

Automatic : Automatic

Condition : New

Electric Supply : 415V AC, 3 Phase, 50 Hz

Control Panel : Automatic Digital Control Panel

...more

rotary roaster

250,000 Per Piece

1 Piece (MOQ)

The Masala Roasting Machine is used for roasting various types of Spices like Coriander, Fenugreek seeds, Fennel (Saunf), Bay leaf/Cinnamon leaf (Tej Patta), Cumin (Jeera), Sesame etc. The Products are roasted for removing moisture contents, which reduces bacterial growth and increases the life of the Products. The Uniformity of product is achieved by 3 dimensional agitaon by the agitang blades Ÿ Enables even distribuon and roasng of the material, achieving uniformity in the quality of the product, at all the mes. Ÿ Products in the drum, even during the short period of their presence in the heater, rapidly undergo roaster due to heat inera. Ÿ This device has a downward rotaonal discharge system that minimizes the me spent in the drum and thereby prevenng transformaon of the product due to the remnant heat in the roaster, avoiding the product from being burnt.

Usage/Application : Industrial

Machine Type : Automatic

Country of Origin : Made In India

Moc : SS 304 Contact Part

...more

Rotary Dryer

800,000 Per piece

The complete drying plant compromises Rotary Cascade Dryer, Air Heater, Dryer Inlet Hood, Exhaust Hood, Exhaust Air Fan & Ducting and all necessary Controls. Duty : To Dry about 750 Kg/hr. of Chilly Flakes from approximately 20% initial moisture to 8-10 % final moisture. Dryer Drum : 3 Ft Diameter X 28 Ft. long dryer drum fabricated in Stainless Steel plate SS-304 , with internal flights and lifters fabricated and bolted to Stainless steel angle sections welded to the shell plates to ensure adequate contact between the drying air and the material being processed. The drum is fitted with two cast or forged steel tyres, mounted on carbon steel spacer blocks fitted to a reinforcing band. The tyres run on four cast or forged steel support rollers shrunk fit on steel shafts with shaft mounted spherical roller bearing plummer blocks. A segmental cast steel chain ring is fitted around the periphery of the dryer drum. Support Frames: The complete dryer drum assembly is supported on two fabricated carbon steel roller support frames, the feed end support frame carrying the locating roller assemblies. Both roller support frames are fitter with safety guards. Drum Drive: The dryer drum is driven by a T.E.F.C. electric motor through V-belt drive, gearbox, pinion and chain to the drum drive chain wheel. Motor, gearbox and V-belt, etc. are mounted on a fabricated carbon steel baseplate. All drives are completely enclosed in suitable safety guards. Air Heater : The drying air is provided by means of Electrical Operated, firing into a refractory lined carbon steel combustion chamber connected to the dryer inlet end hood. It can also be operated with Electrical Heater of 30 KiloWatts rating. Inlet End Hood :The inlet end of the drum is totally enclosed with a Stainless steel fabricated enclosure, complete with labyrinth seal. and stainless steel material inlet chute. The inlet hood is supported by a suitable rolled steel section support structure. Outer End Hood : The outer end of the drum is totally enclosed with a carbon steel fabricated hood complete with inspection access door, exhaust air outlet chute. A labyrinth type flexible seal is fitted to the rear hood plates around the drum opening. The outlet end is supported by a suitable rolled steel section support structure. Exhaust Air Fan : The exhaust air is drawn from the dryer by a centrifugal fan, complete with electric motor, V-belt drive and drive guard. Exhaust Air Ducting : The exhaust air from the dryer is conveyed via a Stainless steel duct from the outlet end hood to the cyclone and from the cyclone to the exhaust fan. A manually operated butterfly type valve damper is fitted in the exhaust duct between the cyclone and exhaust fan. Control System : Inlet air temperature is measured by means of a thermocouple located in the inlet end hood connected to a temperature indicator/recorder. Exhaust air temperature is measured by a thermocouple located in the exhaust air duct connected to a temperature indicator/recorder. The Electrical output is controlled by means of a suitable Thermostat via a suitable transmitter from either of the two temperature indicator controllers. All necessary motor control gear, relays, overloads, etc. and temperature indicators/recorders are housed in a carbon steel control cabinet which will be prewired for correct sequential star-up and operation of the plant.

Frequency : 50/60 Hz

Phase : Three

Country of Origin : Made In India

Brand Name : Fine

Warranty : 1 Year

Voltage : 380-415 V

Material : Mild Steel

Usage : Industrial

...more

Rotary Cascade Dryer

800,000 Per piece

1 piece (MOQ)

The complete drying plant compromises Rotary Cascade Dryer, Air Heater, Dryer Inlet Hood, Exhaust Hood, Exhaust Air Fan & Ducting and all necessary Controls. Duty : To Dry about 750 Kg/hr. of Chilly Flakes from approximately 20% initial moisture to 8-10 % final moisture. Dryer Drum : 3 Ft Diameter X 28 Ft. long dryer drum fabricated in Stainless Steel plate SS-304 , with internal flights and lifters fabricated and bolted to Stainless steel angle sections welded to the shell plates to ensure adequate contact between the drying air and the material being processed. The drum is fitted with two cast or forged steel tyres, mounted on carbon steel spacer blocks fitted to a reinforcing band. The tyres run on four cast or forged steel support rollers shrunk fit on steel shafts with shaft mounted spherical roller bearing plummer blocks. A segmental cast steel chain ring is fitted around the periphery of the dryer drum. Support Frames: The complete dryer drum assembly is supported on two fabricated carbon steel roller support frames, the feed end support frame carrying the locating roller assemblies. Both roller support frames are fitter with safety guards. Drum Drive: The dryer drum is driven by a T.E.F.C. electric motor through V-belt drive, gearbox, pinion and chain to the drum drive chain wheel. Motor, gearbox and V-belt, etc. are mounted on a fabricated carbon steel baseplate. All drives are completely enclosed in suitable safety guards. Air Heater : The drying air is provided by means of Electrical Operated, firing into a refractory lined carbon steel combustion chamber connected to the dryer inlet end hood. It can also be operated with Electrical Heater of 30 KiloWatts rating. Inlet End Hood :The inlet end of the drum is totally enclosed with a Stainless steel fabricated enclosure, complete with labyrinth seal. and stainless steel material inlet chute. The inlet hood is supported by a suitable rolled steel section support structure. Outer End Hood : The outer end of the drum is totally enclosed with a carbon steel fabricated hood complete with inspection access door, exhaust air outlet chute. A labyrinth type flexible seal is fitted to the rear hood plates around the drum opening. The outlet end is supported by a suitable rolled steel section support structure. Exhaust Air Fan : The exhaust air is drawn from the dryer by a centrifugal fan, complete with electric motor, V-belt drive and drive guard. Exhaust Air Ducting : The exhaust air from the dryer is conveyed via a Stainless steel duct from the outlet end hood to the cyclone and from the cyclone to the exhaust fan. A manually operated butterfly type valve damper is fitted in the exhaust duct between the cyclone and exhaust fan. Control System : Inlet air temperature is measured by means of a thermocouple located in the inlet end hood connected to a temperature indicator/recorder. Exhaust air temperature is measured by a thermocouple located in the exhaust air duct connected to a temperature indicator/recorder. The Electrical output is controlled by means of a suitable Thermostat via a suitable transmitter from either of the two temperature indicator controllers. All necessary motor control gear, relays, overloads, etc. and temperature indicators/recorders are housed in a carbon steel control cabinet which will be prewired for correct sequential star-up and operation of the plant.

Country of Origin : India

Specialities : Precise Design, Fine Finish

Voltage : 220V

Automatic : Automatic

Power Source : Electric

Color : Blue

Finishing : Polished

Material : MS

...more

Ribbon Blender

175,000 Per piece

Lithotech Ribbon Blender comprises of U-shaped container, transmission parts and ribbon agitating blades which usually have double or triple layers with outside screw gathering the material from sides to center and inside screw transmitting the material from center to sides to form convection mix. Ribbon Blender has a good result in the mix of viscosity or cohesion powder and of putting liquid and mash material into the powder. The cylinder cover can be fully open so as to clean and change the device.

Capacity : 50 Kg/hr

Brand Name : Fine

Power : 2 HP

Frequency : 50/60 Hz

Voltage : 230 V

Automatic Grade : Semi Automatic

Material : Mild Steel

Application : Industrial

...more

Pin Mill

280,000 Per Piece

1 Piece (MOQ)

This machine is used for very so materials like sugar, salts, chemicals, dyestuffs, etc for medium fine to fine grinding. This material is centrally fed into the machine chamber. The grinding takes place between a high speed rotor consisng of a large number of pins and a staonary stator. The discharge takes place through the perforated screen throughout the periphery. We are the leading manufacturer of Pin Mill Machine and our product is made of good quality. Product details:-Also Available model Model FPP-450 Horse Power (H.P) 25 Capacity (Kgs/hr)Upto 400 - 450 Max permissible Feed size 15 Fineness Range 60 to 200 Mesh BSS Abrasiveness Handled Very Low Hardness Handled Upto 3 mohs

Country of Origin : India

Type : Pin Mill

Voltage : 220V

Automatic Grade : Semi Automatic

Condition : New

Color : Green

...more

Micro Pulverizer

100,000 Per Piece

1 Piece (MOQ)

We manufacture and export Micro Pulverization Machine in Vasai, Maharashtra, India. These micro pulverizer utilized for soft materials like chemicals, dyestuff, foodstuff, pharma bulk drugs etc. for fine grinding. Since the pulverizer is used vastly for chemicals & bulk drugs, and other heat sensitive materials, it has a built-in water jacket to control the temperature in the grinding chamber. It is ulized for so materials like chemicals, dyestuffs, foodstuff, pharmaceucal, bulk drugs, etc. for fine grinding. Since the machine is used vastly for chemicals &bulk drugsand other heat sensive materials, it has a built in water jacket to control the temperature in the grinding chamber. The grinding takes place through arion between the high speed swinging hammers and the serrated liners. Due to the very high speed and a small chamber, a higher fineness is achieved as compared to hammer mill.

Country of Origin : India

Specialities : Excellent Functionality, Less Maintenance, Easy To Use

Voltage : 220V

Operating Type : Semi Automatic

Pressure : High Pressure

Color : Metallic

Driven Type : Electric

Material : Mild Steel

...more

Masala Roasting Machine

250,000 Per piece

1 piece (MOQ)

The Masala Roasting Machine is used for roasting various types of Spices like Coriander, Fenugreek seeds, Fennel (Saunf), Bay leaf/Cinnamon leaf (Tej Patta), Cumin (Jeera), Sesame etc. The Products are roasted for removing moisture contents, which reduces bacterial growth and increases the life of the Products. The Uniformity of product is achieved by 3 dimensional agitaon by the agitang blades Ÿ Enables even distribuon and roasng of the material, achieving uniformity in the quality of the product, at all the mes. Ÿ Products in the drum, even during the short period of their presence in the heater, rapidly undergo roaster due to heat inera. Ÿ This device has a downward rotaonal discharge system that minimizes the me spent in the drum and thereby prevenng transformaon of the product due to the remnant heat in the roaster, avoiding the product from being burnt.

Brand Name : Fine

Automatic Grade : Automatic

Material : Stainless Steel

Driven Type : Geared Motor

Voltage : 415 V AC

Country of Origin : Made In India

...more

Masala Making Machine

170,000 Per Piece

We are manufacturing and exporting Chopper Machine from Vasai, Maharashtra, India. This Food Chopper has been specially designed for granulating & cutting various materials like foodstuffs, agro products, ayurvedic herbs etc. into small pieces of required size with a minimum of powder content. In Electric Food Chopper there is no heat generation while grinding thereby retaining important properties like aroma, taste, flavour & colour.Applications: Tea-cut Senna leaves Crushed chillies for pizza toppings Crushing of various Ayurvedic herbs Chopped / minced / granulated onions Granulating of food colours, gum, asafoetida Note:Available Models: Model FCH-12 FCH-16 FCH-24 FCH-32 Hose Power (H.P) 5 7.5 15 25 Capacity (Kgs/hr)Upto 150 350 600 1000 Max permissible Feed size 8" 10" 15" 15" Fineness Achievable Piece of required size with minimum of powder Abrasiveness Handled 2 Hardness Handled Upto 3

Brand Name : Lithotech Engineers LLP

Production Capacity : 50 to 75 kg./hour

...more

Impex Pulverizer

155,000 Per piece

1 piece (MOQ)

Impex Pulverizer is one among the wide range of Industrial Crushers that is designed for medium fine grinding of soft or semi hard materials Impex Pulverizer is a screenless pulverizer suitable for grinding hard and brile materials like turmeric, minerals, etc. to a fineness of 100 to 300 Mesh BSS. It is done by connuous impact of rotang hammers against grinding liners. The raw material is fed into the rotary feeder from inlet hopper and spills into the grinding chamber. Strong hammering acon breaks lumps into small parcles. At the same me the blower sucks the air towards the whizzer classifier. Whizzer classifier doesn't allow oversize parcles to pass and returns it into the grinding chamber, where aer regrinding the desired fineness is achieved.

Country of Origin : India

Type : Pulverizer Machine

Voltage : 220V

Application : Grinding

Automatic Grade : Automatic

Condition : New

Driven Type : Electric

Material : Mild Steel

...more

Impact Pulverizer

155,000 Per piece

1 piece (MOQ)

Impact Pulverizer is one among the wide range of Industrial Crushers that is designed for medium fine grinding of soft or semi hard materials Impex Pulverizer is a screenless pulverizer suitable for grinding hard and brile materials like turmeric, minerals, etc. to a fineness of 100 to 300 Mesh BSS. It is done by connuous impact of rotang hammers against grinding liners. The raw material is fed into the rotary feeder from inlet hopper and spills into the grinding chamber. Strong hammering acon breaks lumps into small parcles. At the same me the blower sucks the air towards the whizzer classifier. Whizzer classifier doesn't allow oversize parcles to pass and returns it into the grinding chamber, where aer regrinding the desired fineness is achieved.

Frequency : 50 Hz

Country of Origin : Made In India

Warranty : 1year

Voltage : 415 V

Brand Name : Fine

Application : Industrial

...more

Hammer Mill

290,000 Per piece

1 piece (MOQ)

The most versale machine that is used to grind almost all materials like spices, foodstuffs, chemicals, ayurvedic herbals, minerals and other miscellaneous materials. The grinding takes place between the high speed swinging hammers and top/side liners. Once the parcle size reduces to that of the perforated screen at the boom, it will be discharged through the hopper. The fineness of the material can be controlled by changing the speed of the rotor (hammer), content of serraons on liners, number of hammers and diameter of perforaon on the screen. Hammer mill pulveriser is one of the earliest and most often used size reduction devices. It consists of a number of hammers (typically four or more) hinged on a focal shaft and enclosed safely inside a strong metal container. Our offering is powerful device used to pulverise and fracture various feed materials.

Country of Origin : India

Specialities : Excellent Functionality, Less Maintenance, Easy To Use

Voltage : 220V

Operating Type : Semi Automatic

Pressure : High Pressure

Condition : New

Color : Light Green

Driven Type : Electric

Material : Mild Steel

...more

Gyro Sieving Machine

90,000 Per Piece

1 Piece (MOQ)

Gyro Sieving Machine is a circular highly efficient gyratory screen with adjustable multiplane three component mechanical vibration. The heart of Vibro Sifter is the robust specially made vibrator motor which is designed for long trouble free continuous operation. The vibrator motor has double extended shaft fitted at each end with variable eccentric weight. Motor is rigidly mounted on circular vibrating table on rugged springs. Number of interchangeable spacing frames having discharge outlets along with tensions rings fitted with screens cloth can be mounted one on top of the other, on the Vibrating table with the help of clamp rings. D.P. Vibro Sifter is the most efficient screening machine for any dry and wet sieving application.

Country of Origin : India

Type : Sieving Machine

Voltage : 220V

Automatic Grade : Automatic

Color : Light Green

Driven Type : Electric

Brand Name : Lithotech Engineers LLP

Condition : New

...more

Grinding Mill

160,000 Per Set

We are manufacturing and exporting Grinding Mill from Vasai, Maharashtra, India. This is a screenless pulveriser used for grinding soft to medium hard materials into super-fine powder. The industrial grinding machine has a built-in water jacket to keep down the temperature in the machine chamber. This is a screenless pulveriser used for grinding so to medium hard materials into super fine powder. The machine have built-in water jacket to keep down the temperature in the machine chamber. This machine is generally used for superfine grinding of food dyes, industrial dye intermediates, pharmaceucals drugs, chemicals, etc. The feed is through the feeder screw that feeds material centrally into the machine chamber. The grinding takes place due to arion between a high speed rotang rotor having six wear resistant ps and side liners on both side of the ps and also a turbo effect. The annular gap plate controls the flow of materials through the mill. In other words it regulates the fineness of the material. The powder is discharged through the boom hopper.

Material : Stainless Steel And Mild Steel

Brand Name : Fine

Country of Origin : Made In India

Power : 200 KW

Voltage : 380 V - 415 V

Phase : Three

Frequency : 50 Hz

...more

Food Chopper

170,000 Per Piece

We are manufacturing and exporting Chopper Machine from Vasai, Maharashtra, India. This Food Chopper has been specially designed for granulating & cutting various materials like foodstuffs, agro products, ayurvedic herbs etc. into small pieces of required size with a minimum of powder content. In Electric Food Chopper there is no heat generation while grinding thereby retaining important properties like aroma, taste, flavour & colour.Applications: Tea-cut Senna leaves Crushed chillies for pizza toppings Crushing of various Ayurvedic herbs Chopped / minced / granulated onions Granulating of food colours, gum, asafoetida Note:Available Models: Model FCH-12 FCH-16 FCH-24 FCH-32 Hose Power (H.P) 5 7.5 15 25 Capacity (Kgs/hr)Upto 150 350 600 1000 Max permissible Feed size 8" 10" 15" 15" Fineness Achievable Piece of required size with minimum of powder Abrasiveness Handled 2 Hardness Handled Upto 3

Power : 3 HP

Voltage : 220V

Country of Origin : Made In India

Material : Mild Steel

Capacity : 75 Kg/hr

Brand Name : Fine

Application : Industrial

...more

Electric Tray Dryer

365,000 Per Piece

We are a preferable exporter, manufacturer of Tray Dryer in Vasai, Maharashtra, India. Tray dryer is an Insulated Chamber within which hot air is on continuously circulated. Forced convection heating takes place to remove moisture from the solids placed in trays.Trolleys containing trays are dragged inside the dryer. Electrical heating elements are used to generate heat inside the dryer. Tray drier is an Insulated Chamber within which hot air is connuously circulated. Forced convecon heang takes place to remove moisture from the solids placed in trays. Trolleys containing trays are dragged inside the drier. Electrical heang elements are used to generate heat inside the drier.

Power : 14 HP

Country of Origin : Made In India

Brand Name : Fine

Frequency : 50 Hz

Max Temperature : 100 Degree Celsius

Number Of Tray : 48

Voltage : 415 V

Power Source : Electric

Phase : Three Phase

Material : Mild Steel

...more

Commercial Spice Grinder Machine

500,000 Per Units

Usage/Application : Commercial

Motor Power : 15 HP

Brand Name : Fine

Voltage : 415 V AC

Country of Origin : Made in India

Material : MS and SS

...more

chopper machine

170,000 Per Piece

1 Piece (MOQ)

We are manufacturing and exporting Chopper Machine from Vasai, Maharashtra, India. This Food Chopper has been specially designed for granulating & cutting various materials like foodstuffs, agro products, ayurvedic herbs etc. into small pieces of required size with a minimum of powder content. In Electric Food Chopper there is no heat generation while grinding thereby retaining important properties like aroma, taste, flavour & colour.Applications: Tea-cut Senna leaves Crushed chillies for pizza toppings Crushing of various Ayurvedic herbs Chopped / minced / granulated onions Granulating of food colours, gum, asafoetida Note:Available Models: Model FCH-12 FCH-16 FCH-24 FCH-32 Hose Power (H.P) 5 7.5 15 25 Capacity (Kgs/hr)Upto 150 350 600 1000 Max permissible Feed size 8" 10" 15" 15" Fineness Achievable Piece of required size with minimum of powder Abrasiveness Handled 2 Hardness Handled Upto 3

Material : Mild Steel

Automation Grade : Automatic

Color : Light Green

Country of Origin : India

...more

Blending Machine

140,000 - 200,000 Per Piece

1 Piece (MOQ)

Lithotech Ribbon Blender comprises of U-shaped container, transmission parts and ribbon agitating blades which usually have double or triple layers with outside screw gathering the material from sides to center and inside screw transmitting the material from center to sides to form convection mix. Ribbon Blender has a good result in the mix of viscosity or cohesion powder and of putting liquid and mash material into the powder. The cylinder cover can be fully open so as to clean and change the device.

Brand Name : Lithotech Engineers LLP

Driven Type : Electric

Condition : New

Automatic Grade : Automatic

Application : Blending

Country of Origin : India

...more

Blender Cum Roaster

1 Piece (MOQ)

The complete drying plant compromises Rotary Cascade Dryer, Air Heater, Dryer Inlet Hood, Exhaust Hood, Exhaust Air Fan & Ducting and all necessary Controls. Duty : To Dry about 750 Kg/hr. of Chilly Flakes from approximately 20% initial moisture to 8-10 % final moisture. Dryer Drum: 3 Ft Diameter X 28 Ft. long dryer drum fabricated in Stainless Steel plate SS-304, with internal flights and lifters fabricated and bolted to Stainless steel angle sections welded to the shell plates to ensure adequate contact between the drying air and the material being processed. The drum is fitted with two cast or forged steel tires, mounted on carbon steel spacer blocks fitted to a reinforcing band. The tires run on four cast or forged steel support rollers shrunk to fit on steel shafts with shaft-mounted spherical roller bearing Plummer blocks. A segmental cast steel chain ring is fitted around the periphery of the dryer drum. Support Frames : The complete dryer drum assembly is supported on two fabricated carbon steel roller support frames, the feed ends support frame carrying the locating roller assemblies. Both roller support frames are fitter with safety guards. Drum Drive : The dryer drum is driven by a T.E.F.C. electric motor through a V-belt drive, gearbox, pinion, and chain to the drum drive chain wheel. The motor, gearbox, V-belt, etc. are mounted on a fabricated carbon steel baseplate. All drives are completely enclosed in suitable safety guards. Air Heater : The drying air is provided using Electrical Operated, firing into a refractory lined carbon steel combustion chamber connected to the dryer inlet end hood. It can also be operated with an Electrical Heater of 30 KiloWatts rating. Inlet End Hood : The inlet end of the drum is enclosed with a Stainless steel fabricated enclosure, complete with a labyrinth seal and stainless steel material inlet chute. The inlet hood is supported by a suitable rolled steel section support structure. Outer End Hood: The outer end of the drum is enclosed with a carbon steel fabricated hood complete with an inspection access door, and exhaust air outlet chute. A labyrinth-type flexible seal is fitted to the rear hood plates around the drum opening. The outlet end is supported by a suitable rolled steel section support structure. Exhaust Air Fan : The exhaust air is drawn from the dryer by a centrifugal fan, complete with an electric motor, V-belt drive, and drive guard. Exhaust Air Ducting : The exhaust air from the dryer is conveyed via a Stainless steel duct from the outlet end hood to the cyclone and from the cyclone to the exhaust fan. A manually operated butterfly-type valve damper is fitted in the exhaust duct between the cyclone and the exhaust fan. Control System : Inlet air temperature is measured using a thermocouple located in the inlet end hood connected to a temperature indicator/recorder. Exhaust air temperature is measured by a thermocouple located in the exhaust air duct connected to a temperature indicator/recorder. The Electrical output is controlled using a suitable Thermostat via a suitable transmitter from either of the two temperature indicator controllers. All necessary motor control gear, relays, overloads, etc. and temperature indicators/recorders are housed in a carbon steel control cabinet which will be prewired for correct sequential start-up and operation of the plant.

Driven Type : Electric

Automatic Grade : Automatic

Voltage : 220V

Country of Origin : India

...more

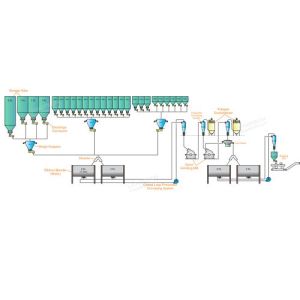

Automatic Batching system

1 Piece (MOQ)

A Sample Process flow of the system Silo of 1 Ton (1 unit): This Silo would be mounted on the load cell and would indicate the weight of the material filled in it. A complete batch including different ingredients would be made here manually by checking the weight of each item while filling. Vibratory Feeder (1 unit): This Feeder would be placed each at the bottom of the Silo to feed the material in the Z Type Elevator. Z-Type Elevator: This would carry the material from the discharge of the Vibratory feeder and will convey it to the Mixer via the Diverter. Y – Diverter: This would be mounted at the outlet of Z Elevator. It would be pneumatically operated by a manual solenoid valve and would alternately feed the 2 Mixers Mixer 750 Kg (Twin): This would thoroughly mix the Ingredients received from the weigh hopper. It has a 10HP main motor Mixer. The discharge valve below it is of Flap type operated by pneumatic cylinders, which while in closed condition doesn’t allow any material to get accumulated over it. Collection Hopper (1 Ton): This would be mounted below the 2 mixers and would take the discharge from both of the mixers Screw Conveyor (1 unit): This would convey the material from the outlet of the Collection Hopper and would feed at the inlet of the Bagging Station. Bagging Station (1 Unit): The bags of 50 Kg each would be filled here it consists of two outlets for each where the material would come alternately. While one bag is getting filled in the 1st outlet, the 2nd would be stopped and will be replaced with a new bag manually. The Weight scale is placed below the two outlets which would automatically weigh 50 Kg and then switch the discharge to the other outlet.

Application : Multiwork

Voltage : 220V

Country of Origin : India

Automation Grade : Automatic

...more

auto batching system

700,000 Per piece

Brand Name : Fine

Automation Grade : Automatic

Voltage : 415 V

Country of Origin : Made in India

...moreOpening Hours

Lithotech Engineers LLP was established in the year 1993 in Maharashtra, India. We are a manufacturer and trader of mill machines, industrial dryers, and a lot more.

Our commitment to excellence has taken us many miles ahead of our competitors. We work hard to add value to our customer\'s business by contributing quality products that are built as per our customer\'s needs. We are providing all types of Lathe machines like All Geared Lathe, vertical turning and Heavy Duty lathe machines.

The main features of the machines are high quality, easy to operate, heavy-duty castings, extensive lubrication system, interchangeability of parts through standardization & quality control, and clutch drive in all geared machines to ensure perfect grip.

Why Choose Us?

We have modern technology in machine tools. The company aims to manufacture products with high-quality raw materials to serve the industry with quality products with innovation and quality at very competitive prices. Highly efficient and wear & tear resistant, these machines require low maintenance.

We have a Dealership network in all the major cities in India. Today we are the leading supplier of machine tools. We have highly qualified and experienced professionals who are providing world-class technology with maintaining international standards and cost-effective services.

Choose to deal with us and order from us today.