Water Ring Vacuum Pump

Water ring vacuum pump Silent and considerably vibration free running Needs no silencer. Mechanical shaft seals on either end of shaft Maximum vacuum using water as sealant at 300 Centigrade and at sea level conditions :Single stage models will be 700 mm Hg. Double stage models will be 720 mm Hg. Negligible maintenance and easy overhauling procedures. Modification for use as compressor possible.

...more

VACUUM PUMPING UNITS

In case single Vacuum pumps (liquid ring pumps, rotary vane pumps) are not suited for a certain process due to their pumping speed and / or their ultimate vacuum, a combination with twin lobe pumps can be used. These Vacuum Pumping Units consist of rotary vane pump twin lobe pumps as fore-pump and rotary vane pump or liquid ring pump as backing pump. The fore-pump picks up oil necessary for its lubrication from the backing pump. The exhaust from the fore - pump is connected to the suction side of the backing pump thereby giving advantage of high pumping speed at higher vacuum. These units are highly energy efficient and consume less power than conventional single vacuum pumps. These pumping units are of compact design and mounted on base frames ready for use. They are tailor - made and are offered to suit user's requirements. APPLICATIONS :- Evaporative Concentration, Vacuum Distillation, Polymerization, Crystallization, Vacuum Impregnation, Vacuum Drying, Sterilization, Vacuum Cooling, Object Metallising, Roll Metalllisation, semi-conductor Processing, Manufacture of Vacuum & Microwave Tubes, Manufacture of GLS Automotive& Miniature Lamps, Tube Light Production, Sintering, Brazing, Electron Beam Welding, Heat Treatment Ionic Nit riding, Tool Coating, Vacuum Casting, Degassing & Refining, Plasma Welding, Evaporation, Sputtering, Space Research and Development Applications.

...more

VACUUM / PRESSURE PUMPS

These are rotary sliding vane, oil lubricated, belt driven type and find applications in printing, labeling, vacuum forming, filling and sealing machines. Pumps are compact, light weight and can be placed inside original equipment. UNIQUE FEATURES • Both ball bearings are located on drive end of the rotor shaft and are housed in one end cover which has foundation holes for fitting on base plate. On removal of six bolts, the other end cover along with the stator comes apart exposing rotor and vanes for servicing. • The grease filled bearings are separated from other parts with oil seals thus preventing contact with sucked in media. • The oil from exhaust is baffled and re-circulated, thus eliminating oil drops being thrown out from exhaust nozzle. • Model LV 150 has a built-in-suction filter an oil re-circulation system which enables the baffled oil to return to oil cup. • Both the models are V-belt driven to give following advantages :- Vibration-free running , Displacement variation possible by changing pulley ratio , can be located conveniently inside equipment. SERIES LVThese pumps are rotary sliding vane, oil lubricated and directly coupled to three phase 1440 RPM A. C. motor, both mounted on a study base plate. These pumps are designed to give vacuum and pressure at the same time and eliminates the need for two separate units, one or vacuum and one for pressure. These pumps are specially designed for printing and packaging machines. FEATURESSpecially treated steel vanes ensures silent running and negligible wear on stator and rotor slots.Unique lubrication system positively feeds minimum quantity of oil to all important points. Oil from the exhaust is baffled, collected and returned back to oil chamber. Incoming air passes through fine filter in case in suction box before entering pumpRegulation of vacuum and pressure can be done precisely. Complete unit with motor is compact and vibration free hence suitable for mounting inside any equipment.

...more

Vacuum Pressure Pumps

These are rotary sliding vane, oil lubricated, belt driven type and find applications in printing, labeling, vacuum forming, filling and sealing machines. Pumps are compact, light weight and can be placed inside original equipment.

...more

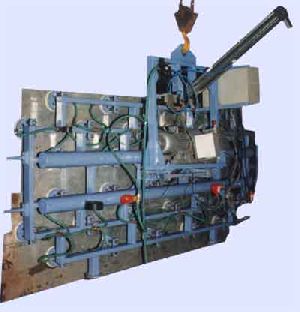

vacuum lifting devices

The "Vaculift" range of lifting and transporting systems are custom-designed and are suitable for handling sheet metals, plates, laminates, glass, granite, barrels, cartons, drums, etc. The equipment incorporates vacuum generators with safety devices, drive units, buffer reservoir, valves, electrical switchgear and other accessories, all supported on a structural frame. Specially design rubber pads holds the work piece. wotk-piece. Vaculift improves overall plant productivity which substantial savings in handling times and labour cost. Pay-back period is very short.

...more

Turbine Blowers

PRINCIPLE OF OPERATION : These blowers consists of a dynamically balanced impeller which revolves in a stator-cum-compression chamber having very fine clearances between them. The impeller is fitted directly on to the motor shaft. Both the suction and pressure openings are located on the outer periphery of the stator to reduce impedence to the air flow thereby developing vacuum and pressure. Since the impeller rotates with no contact between itself and the casing, there is no wear and tear and requires no lubrication APPLICATIONS : Manufacturing of textiles, Measuring, medical and laboratory equipment, Printing and paper handling, Vacuum packaging, Waste water treatment, Reprographics Industry, Aeration of fluids, Pneumatic Conveying, Plastic Industry, Industrial Ovens, Vacuum cleaners, Air Pollution monitoring equipment.FEATURES : • No lubrication is required since there is no friction and hence the air is absolutely oil free. • Practically nil maintenance cost. • Extremely compact units and can be mounted inside the machines • Silencer ensures low noise level

...more

rotary vacuum pumps

LVV SERIES UNIQUE FEATURES • A unique design of lubricating system positively feeds minimum quantity of oil to important points. The oil from the exhaust is baffled, collected and returned back to oil chamber. This way not only the intervals between oil top up is prolonged, but also helps to keep the atmosphere in the premises free of oil smoke to some extent. • Specifically heat treated fibre vanes are used in ACMEVAC pumps in place of steel vanes. The advantages are silent running, and negligible wear on stator, end covers and rotor slots • ACMEVAC pumps are driven by V-belt covered with belt guard to give vibration free operation, and are fan cooled. • The complete unit with motor and base plate is most compact for its capacity and due to its vibration free running is suitable for mounting inside the equipment. • All the models in LVV series can be modified to suit specific application so that smallest possible pump with minimum power consumption can be offered to the user. APPLICATIONS • Pharmaceutical, Chemical & Industrial Machines. • Filling, Transferring, Holding. • Conveying, packing, Filtering.

...more

Rotary High Vacuum Pumps

This series of vacuum pumps are rotary sliding vane, oil immersed type. The rotor, stator and end covers are made up of high nickel content cast iron and are machined to very fine tolerance. These pumps are ideal for handling dry and clean air. Gas ballast and belt guard are provided as standard equipment. FEATURES • Exhaust valve is designed to eliminate "rapping" noise. • Unique construction of the pump totally eliminates the sucking of air through the shaft seal. • Pumps can also be operated with SAE-30 motor oil instead of vacuum oil• Water Cooling Arrangement can be provided if required at extra cost.OPTIONAL ACCESSORIES (at extra cost) Non-Return ValveMoisture TrapVacuum Gauge with regulatorSINGLE STAGE

...more

Liquid Ring Vacuum Pumps

OUTSTANDING FEATURES: • Silent and considerably vibration free running • Needs no silencer. • Mechanical shaft seals on either end of shaft • Maximum vacuum using water as sealant at 300 Centigrade and at sea level conditions : Single stage models will be 700 mm Hg. Double stage models will be 720 mm Hg. • Negligible maintenance and easy overhauling procedures. • Modification for use as compressor possible. MATERIAL OF CONSTRUCTION :Bronze/Stainless steel impeller, Stainless steel shaft and all other contact parts in cast iron. Complete Stainless Steel Pumps are also offered.

...more

Industrial Vacuum Cleaners

The "Swiss Vac" range of Industrial Vacuum Cleaners are suitable for wet and dry applications and have a patented triple filter system for protection of blower. Motors are continuously rated. Collection container is made of SS-304. Various nozzles and accessories are available. The machines are compact, and easy to maneuver

...more

High Vacuum Pump

This series of vacuum pumps are rotary sliding vane, oil immersed type. The rotor, stator and end covers are made up of high nickel content cast iron and are machined to very fine tolerance. These pumps are ideal for handling dry and clean air. Gas ballast and belt guard are provided as standard equipment.

...more

FLOOR SCRUBBER-DRIERS

Vacutec FS Series of Floor Scrubbers are deisgned to cleanse & shine all types of dirty floors where sticky dirt cannot be cleaned by traditional brooms & wet cloth mopping.FEATURES : • It cleans & gives bright look all types of dirty floors instantly by its powerful electrical operated circular nylon brush & built in liquid detergent tank. • With simple construction it is easy to operate & no special training is required for the operator. • The handle is fully insulated with PVC coating for operator safety. • There is no absolutely no wear & tear except the nylon brush. Spare brushes are provided at extra cost. APPLICATIONS :Can be used on any type of floors like marble, granite, pvc & cement. Ideal for use in airport lounges, hotels, hospitals, pharmaceuticals plants & offices.

...more

Direct Drive Vacuum Pumps

ACMEVAC Direct Drive, Oil-Sealed, Rotary High Vacuum Pumps are compact in size, as they are directly mounted on the motor flange. These pumps are light weight, well balanced and have exceptional size to performance ratio. These pumps have high pumping speeds and high water-vapor tolerance. The oil consumption is extremely low and they are air cooled.

...more

Direct Drive High Vacuum Pumps

ACMEVAC Direct Drive, Oil-Sealed, Rotary High Vacuum Pumps are compact in size, as they are directly mounted on the motor flange. These pumps are light weight, well balanced and have exceptional size to performance ratio. These pumps have high pumping speeds and high water-vapor tolerance. The oil consumption is extremely low and they are air cooled APPLICATIONSThese pumps are used extensively in industry and laboratories for production of medium and high vacuum. They are used as backing pumps in series with roots blowers, diffusion pumps etc. These pumps find applications in vacuum coating, molecular distillation, vacuum metallurgy, freeze drying, vacuum impregnation, air conditioning and refrigeration, vacuum lifting devices, packaging machines etc. SALIENT FEATURES • Solenoid operated anti-suck back valve to prevent oil in-rush into the system in the event of stopping the pump and power failure. • Provides uniform pumping speed. • Gas ballast facility has been provided. This helps in preventing condensation of vapors inside the pump when condensable va pours are being evacuated. • Suitably dimensioned inlet and outlet ducts to minimize conductance losses. • Inlet port is adapted for ISO type quick clamp fittings for ease of assembly and disassembly of pump units. • Vanes are spring loaded and chemically resistant. The non-metallic vanes are dimensionally stabilized, quiet in operation and possess long life. • Quality graded ferrous castings to improve wear resistance. • Aluminum alloy, light weight oil tank with fins is designed to provide heat dissipation. This helps in running the pump cool and quiet. • Heat treated Rotor and shaft to prevent solid particles from getting into the pump chamber. • Flexible high torque coupling with vibration dampening insert. • Pump is supplied with a sturdy steel base and anti-vibration mountings. ACCESSORIES FORE LINE TRAP : This is used to prevent back streaming of oil-vapors into clean pumping systems which employs two stage pumps operating below 0.001 Torr. This design employs ISO type quick clamp fittings for ease of assembly. INLET DESICCANT TRAP : This enables the removal of limited quantities of moisture of low va pour pressures. This design employs ISO type quick clamp fittings for ease of assembly. HANDLE.

...more

diaphragm vacuum pumps

Acmevac offer 100% oil-free Diaphragm Vacuum Pumps/Compressors. They can be used either as vacuum pumps or oil-free compressors and are designed for delivery of uncontaminated air, gases or va pours. They are suitable for producing oil-free compressed air or vacuum. ADVANTAGES: • Diaphragm type - hence no rubbing of parts and negligible wear & tear • Practically maintenance free.• No lubrication required, hence oil - free • Low operational cost of equipment. This results from the modest cost for replacement of diaphragm and valves. FEATURES:• Heads are made of aluminum alloy castings • Diaphragms are made of neoprene rubber or other elastomers depending on applications • Specially designed motors in single - phase and three-phase constructions • Pumps are mounted on rubber pads for silent, vibration-free running • Due to compact design, these pumps are ideal for laboratories and original equipment manufacturers • Compact, light-in-weight, hence portable APPLICATIONS: Pollution Monitoring Equipment, Chemical Analyzers, Laminating press, Material Handling Equipment, Labeling Machines, Plastic Welding Machines, Gas Welding Machines, Soldering iron, Agitation of Chemicals in Tanks, Aeration.

...more

Diaphragm Vacuum Pump

Acmevac offer 100% oil-free Diaphragm Vacuum PumpsCompressors. They can be used either as vacuum pumps or oil-free compressors and are designed for delivery of uncontaminated air, gases or va pours. They are suitable for producing oil-free compressed air or vacuum.

Specialities : • Heads are made of aluminum alloy castings, • Diaphragms are made of neoprene rubber or other Etc.

...moreBe first to Rate

Rate This