Magnetic Separator Pulley

Get Price Quote

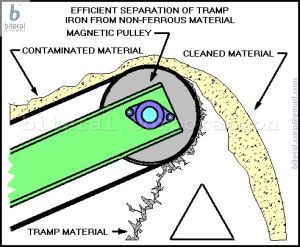

We are offering magnetic separator pulley. Pmt magnet pulley is a self-cleaning separator. It is installed as head pulley in belt conveyor for continuous & automatic removal of iron ferrous particles from product on the belt. Installed at the discharge end of the belt conveyors, magnet pulley are ideal for removal of ferrous particles that cannot be removed by either a plate magnet or suspension magnet due to the depth of conveyed product. Pulley consists of 360 degree magnetic field that retains the iron particles till the belt passes the face of the pulley. Thereafter the iron particles falls behind the divider & the cleaned material due to gravity falls ahead. magnet pulley is an integral part of conveying system and for installation there is no need of any additional setup or arrangement. The key waved shafting of pulley can directly fit into the existing drive of the belt conveyor system. It is very effective in separating tramp iron from feed & grain, coal handling, mining, waste recovery, paper & pulp industries. It is maintenance free and effective separator with high percentage of separation of iron particles. magnet pulley are available in various sizes with key waved shafting to suit the specific requirements. They are also available with "gemini rare earth powerful magnets" for greater level of iron separation

Permanent Magnetic Pulley

Get Price Quote

We are offering permanent magnetic pulley please write to us for your specific need on biteral.

Best Deals from Magnetic Components

Magnetic Pulley

Get Price Quote

Permanent magnetic pulleys are ideal magnetic products used as head pulleys in belt conveyors. These pulleys offer superior removal of ferrous contamination like nails, spikes, nuts, bolts, cans, and wire from material conveyor with maintenance free operation. Whatever your application is, a magnet is a low cost way to remove that unwanted ferrous metal from your waste stream. They require very little maintenance and can last for years with proper care. Applications: Waste recovery Feed & grain Mining Recycling Applications Cement Coal Handling Plant Salt processing industries Glass Paper Refractory Minerals (e.g. Bauxite)

Magnetic Pulley

Get Price Quote

Our Magnetic Pulley is used to replace the drive pulley at the end of conveyor belts. The Magnetic Pulley extracts the iron particles from the flowing materials and carries them to the underside of the belt where they are removed and collected. Our Magnetic Pulley is offered at the market leading prices. Features : Operate without requiring electrical powerPowerful and an-isotropic hard ferrite magnets or high intensity rare earth Nd-Fe-B magnets

Magnetic Pulley

Get Price Quote

Saideep” manufacture a wide range of rare earth and ferrite magnetic pulleys. These pulleys are widely used to remove tramp iron mixed with the material moving on a conveyor belt. The magnet pulleys are always installed at the discharge point of the conveyor to separate tramp iron from the product moving on the conveyor belt. Applications : the permanent magnetic pulley is dual-purpose equipment used for protection of crusher jaws or other machinery and also for purification and concentration of magnetic material from the mines. It has the widest application in food, chemical, ceramic, paper, coal handling, foundry operation and mining industry.

Electromagnetic Pulley

Get Price Quote

Elektromag Magnetic Pulleys are generally used as the head pulley of a conveyor for separating iron pieces from conveyed material. Elektromag Magnetic Pulleys are used for all kinds of bulk materials, such as brown and pit coal, coke, like-stone, cement, rock salt, potash, chamotte, blast furnace, and steel mill slag, foundry sand, gravel, sand, synthetic granulates, grain and feedstuff. They can also be fitted as drive or return pulleys to the discharge end of rubber conveyor belts of existing installations at a later stage. ELEKTROMAG Magnetic Pulleys are mainly designed to remove large iron pieces, such as bolts, screws, wire, strips and tools which could damage conveyor belts, brake sieves, crushers or processing machines. Other Type of separating magnets are available for separating fine iron. In the event of slag separation they server – depending on the granulation – for parting magnetic and non-magnetic components. METHOD OF OPERATION The magnetic field produced is effective on the entire surface in the range of the conveyor belt. The magnetizable iron pieces contained in the conveyor material are influenced by the magnetic field and drawn on the conveyor belt. The iron pieces follow the run of the conveyor belt until they loosen from the magnetic field and, parted from the conveyor material, are discharged in the belt’s run direction underneath the magnetic pulley.

Magnetic Pulley

Get Price Quote

Magnetic Plates are designed in various sizes & strengths to meet with specific operation & plant conditions. Magnetic Plates are widely used for removing Tramp iron such as Bolts, Nuts, Bits of Wire, Nails and other casual Contamination from free flowing materials to protect against occasional damage to the plant caused by bits of iron.

Magnetic Pulley

Get Price Quote

The magnetic field produced is effective on the entire surface in the range of the conveyor belt. The magnetizable iron pieces contained in the conveyor material are influenced by the magnetic field and drawn on the conveyor belt. The iron pieces follow the run of the conveyor belt until they loosen from the magnetic field and, parted from the conveyor material, are discharged in the belt’s run direction underneath the magnetic pulley.

Magnetic Pulley

Get Price Quote

Permanent magnetic pulleys are ideal magnetic products used as head pulleys in belt conveyors. These pulleys offer superior removal of ferrous contamination like nails, spikes, nuts, bolts, cans, and wire from material conveyor with maintenance free operation. Whatever your application is, a magnet is a low cost way to remove that unwanted ferrous metal from your waste stream. They require very little maintenance and can last for years with proper care. Applications: Waste recovery Feed & grain Mining Recycling Applications Cement Coal Handling Plant Salt processing industries Glass Paper Refractory Minerals (e.g. Bauxite)

Magnetic Pulley

Get Price Quote

Elektromag Magnetic Pulleys are generally used as the head pulley of a conveyor for separating iron pieces from conveyed material. Elektromag Magnetic Pulleys are used for all kinds of bulk materials, such as brown and pit coal, coke, like-stone, cement, rock salt, potash, chamotte, blast furnace, and steel mill slag, foundry sand, gravel, sand, synthetic granulates, grain and feedstuff.

electro magnetic pulley

Get Price Quote

electro magnetic pulley, drum machine, magnetic grid, Magnetic Hump

Magnetic Pulley

Get Price Quote

Magnetic Pulley, Copper Slag, Vibration Meter, Vibrating Grizzly Feeder

Magnetic Pulley

Get Price Quote

Magnetic Pulley, Circular Electro Lifting Magnet, Continuous Casting Machine

Magnetic Pulley

Get Price Quote

Magnetic Pulley, Magnetic Equipment, Magnetic Grill, Gyratory Screen