Water Jet Vacuum Pump

Eductor when designed appropriate are able to create full vacuum. They are thus very useful in Chemical Industry where clean vacuum is required. CONNECTIONS Eductors may be supplied in any connections as suitable to the application. They may be flange or thread connected on to clamp hose pipe.

...more

Sump Eductor

Eductors are valuable for Sump Clean-ups with water or sea water as driving force. In Ships they are very useful as there is an individual supply of driving force. These are also useful to take water out of deep wells where ordinary pumps with foot valve suction arrangement fail. Eductors are especially useful in clean-ups of emergency spills as they can be operated from any position and, at a long distance and also as they are self priming SAILENT FEATURES Operates at any Point. Operates at long distance. Operates at any Depth upto 10 m. Operates without priming.

...more

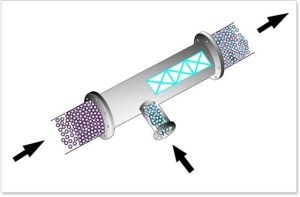

static mixers

Static Mixers CONCEPT When the MIXING BLADE is not rotating it is a Static Mixer. Static Mixing is achieved by placing a series of well-designed obstructions (mixing elements) in a flowing stream. Static Mixers are “Inline” that is they are placed in pipe line. Static Mixers are generally used for “Continuous Mixing”. They may be used in “Batch” mode by providing a recirculation line. There are several advantages of ‘Static Mixers’ such as Low Maintenance Low Capital Cost and Low Energy Requirement It is a special skill to design Static Mixers for a given job such a mixing, blending, Gas - liquid contacting, viscous reaction, heat transfer, mass transfer, dispersion, emulsification, extraction and all those operations where usually agitation is employed. OPTIMAL DESIGNS Optimal Designs for specified Process objectives and for a large range of flow conditions (Reynolds Numbers from 1 to 1000000) are available with MAMKO. MAMKO EXPERIENCE 10 TO 2000 mm DIA40 TO 10000 mm LENGTH ELEMENTS TO CHOOSE Helical Type (3 designs)Hygienic Type (2 designs)Intermeshing / Intersecting Type (12 designs)Crisscross Type (2 designs)Helical Skew Type (1 designs)Scissors Type (1 design)Stretchflow Type (1 design)Whirler Type (3 designs)Low Pressure Drops (6 designs)Zero Shear (3 designs)Annular (3 designs)Pulsating (3 designs)Jet Type (1 design)Diffuser Type (1 design)Butterfly Type (1 design)Lupin Type (1 designs)

...more

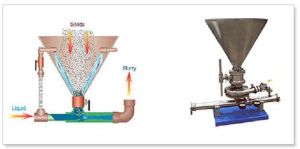

Solids Mixing Eductors

Eductors are effectively used to mix solid powders and transport them to a Blender and Reactor.

...more

PHYSICAL SEPARATORS PLANTS

'Separation' is an important operation in the process Industry. Mamko offer Services where the separation is only dependent on 'Physical forces'. Therefore we do not deal with 'Distillation', 'Absorption' and 'Adsorption'. From the list below you may select and fill up the 'Datasheet' and send your enquiry.

...more

Oily Water Separator

Jet Nozzel

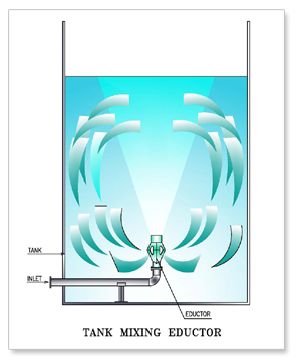

Jet mixing in tanks is usually used either to blend a fresh feed in with the contents of a tank or to obtain a homogeneous mixture within the tank. Batch or Continuous operation is possible and a side entry (i.e. through the tank wall) or an axial jet (i.e. along the axis of the tank) may be used. The Jet is positioned either near the tank floor pointing towards the liquid surface or near the liquid surface pointing towards the tank floor. Jet Mixers are designed specific. The Jet is designed to create appropriate velocities. It is then positioned in the tank at a right position and with a correct angle so that appropriate swirl and vortex is created for the bulk mixing. In some situation more than one jet are required. Industrial Application of Jet Mixing are : Homogenization of Hydrocyclone in storage tanks. Mixing in a ‘Bio Reactor’ and Fermentation applications. Mixing of Chemicals in Effluent Treatment application. Homogenization of low viscosity chemical tanks in various chemical industries Jets are useful on their own as carefully designed low pressure drop Jets or they may be used in combination with other design such as ‘Eductors’ or ‘Static Mixers’. Jets with ‘Eductors’ are used as Eductor Jets and as ‘Aerators’.

...more

jet mixers

Jet Mixing can also be used judiciously for Inline Mixing. There are some situations where Inline Jet Mixer could be preferred over Static Mixers. If one of the Liquid has sufficiently high pressure and if there is not enough space for a Mixer a Standard Jet Mixing arrangement could be used as shown above. Here the ratio of Flow Rates of the Mixing Liquids plays an important role. When the Mixing Liquids viscosities have a large difference that is their ratios are either very high or very low a preferred arrangement is as shown as given below A situation where the density difference in two liquids is high and one invariably settles in at the bottom of a horizontally laid pipe, an arrangement shown below is useful. A typical example of this is Crude Oil flow from an Oil Well to the Tank Farm Mamko have sufficient knowledge of Jet Mixing to enable them to design Inline Jet Mixers as per the process requirement.

...more

INTANK PROCESS PLANT

In Tank Processes are common in Process Industry. Mamko offers several choices of designs for Low viscosity Liquids to high viscosity materials (or non-Newtonian Liquids). Further Mamko also offers a large number of options to Agitated Vessels. Depending upon, the Application, the Process, Tank Geometry and the Properties of liquids, gases and solid Powders ,selection shall be made. Get a Datasheet, filled up and send it after selecting a product from the list given below :

...more

INLINE PROCESS PLANT

INLINE PROCESS Large scale plants have a number of Inline Processes such as Mixing, Homogenization, Dispersion, Aggregation, Flocculation, Emulsification, Deaeration, Suspension, Blending, Micromixing, Extraction, Aeration, Agglomeration, Reactions and Heat Transfer. Mamko has a number of 'Products' to efficiently perform these processes. Get a Datasheet by clicking here and fill it up for your needs by selecting a product below :

...more

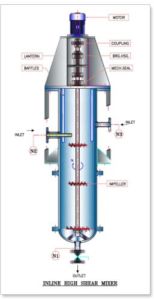

Inline High Shear Mixers

Inline High Shear Mixers / Emulsifier High Shear Mixers are operated at high speeds more than 1000 Rpm with smaller Impellers and has typical design. The concept of High Shear Mixing is detailed in In Tank Processes. This can also be used Inline as shown below.

...more

Hydrocyclone Separator

Solid/Liquid & Liquid/Liquid CONCEPT : The Separation action of hydrocyclones is based on the effect of Centrifugal forces created within the cyclone body. In contrast to sedimenting centrifuges, however, hydrocyclones have no rotating parts and the necessary vortex is produced by pumping the fluid tangentially into a stationary cono-cylindrical body. In principle, however, each hydrocyclones separates particles of the dispersed phase from the liquid (continuous phase) on the basis of density difference between the phases and the separation depends heavily on particle size. Hydrocyclones are used for both Separation of Solid particles as well as a separation of Liquid from other Liquid; for example, separation of Oil droplets from Water as well as separation of Water droplets from Oil. Motive Power of Hydrocyclone design is the centrifugal force created by the entering Liquid. And therefore two important parameters are velocity of the entering Liquid and radius of the Hydrocyclone. Available pressure drops creates a limitation on entry velocity. Then the size remains the important parameter. Therefore removal of very small solid particles or liquid droplets, smaller hydrocyclone is the design requirement. In such cases a no. of Hydrocyclones are placed in a Cluster. APPLICATIONS : Offshore Oil Drilling to clean Seawater. Dredging operation to clean water from Sand or Clay. Recovery of Catalyst in the oil and chemical industries. Separation of sand from sugar cane juice. Removal of silt from well water. Separation of corrosion products in circulating systems in the nuclear power industry. Clean-up of wash water from gas scrubbers for recycling. Clean-up of water in car wash system. Pre-cleaning of primary sewage sludge (1 to 2%). Clarification of seed oil. Dewatering of mine backfill. De-sliming of minerals prior to flotation; this allows easier flotation and requires the use of less reagent. Removal of impurities and ungrounded particles from chalk. Recovery of filter aid. De-sliming of phosphate rock. MATERIAL OF CONSTRUCTION : Carbon Steel Caron Steel + Rubber Lined Carbon Steel + Epoxy Coating Stainless Steel (SS 304,SS 304L,SS 316,SS 316L) Special Alloys – e.g. Duplex. PVC, PV, FRP.

...more

Hydrocyclone Cluster

High Shear Mixer

(For Emulsions, Slurries and Pastes) CONCEPT OF HIGH SHEAR MIXING A high shear zone is created in and around the impeller. These impellers are carefully designed to suit the application and the physical properties of the materials. For example, in case of emulsification the liquids are forced through an extensional flow stream followed by a physical shearing. The liquid is mixed in the bulk by the flow field created by the impeller and sheared in the specially created zone. The best results are thus achieved. MAMKO have 39 Impeller Designs.

...more

Gas Vapour Liquid Separator

Gas (Vapour) Liquid Seperator (Knockout Seperator) Knockout Separator is basically a vapor Liquid Separator, designed mainly on Hydrocyclone principle. It is constructed similar to Hydrocyclone with a Liquid collected at the Bottom. The outlet at where vapor goes upwards may be connected to suction of a blower or to a vacuum.

...more

END CONNECTIONS EQUIPMENTS

Flanges as per ANSI B16.5Flanges as per ANSI B16.9Flanges as per DIN Std.Threaded connections.Wedgeloke connection.Sanitary Fittings. SMS Unions.

...more

EDUCTOR JET PUMP

The Eductor principle whereby high velocity of one fluid creates suction and attracts the second liquid towards itself to effect micro mixing is combined with the JET mixing which is essentially bulk mixing to produce Eductor JETS. Eductor Jets are also effectively used to doze a second liquid into the bulk without an extra pump.

...more

Agitators

Agitators Applications Industrial agitators are machines, which is used in industries like chemical, food, pharmaceutical and cosmetics to process product in a view of: Mixing of liquids having wide range of viscosity. Mixing of Liquids with Solid powder. Promote the reactions of chemical reactants. Increase heat transfer by heating or cooling. Homogenization of bulk storage liquids. Dispersion of immiscible liquids. Gas Liquid Contacting. Gas-Gas Mixing. Mixing of Liquids of extreme Viscosity ratio. Turbulent Mixing of miscible low Viscosity liquid. TYPES OF IMPELLERS Four-bladed, Pitched-blade Turbine. Three-bladed Axial Turbine. Propeller Hydrofoil High Shear Screw Double Ribbon Counter Rotating (Paddle + Anchor) Agitators Applications Industrial agitators are machines, which is used in industries like chemical, food, pharmaceutical and cosmetics to process product in a view of: Mixing of liquids having wide range of viscosity. Mixing of Liquids with Solid powder. Promote the reactions of chemical reactants. Increase heat transfer by heating or cooling. Homogenization of bulk storage liquids. Dispersion of immiscible liquids. Gas Liquid Contacting. Gas-Gas Mixing. Mixing of Liquids of extreme Viscosity ratio. Turbulent Mixing of miscible low Viscosity liquid. TYPES OF IMPELLERS Four-bladed, Pitched-blade Turbine. Three-bladed Axial Turbine. Propeller Hydrofoil High Shear Screw Double Ribbon Counter Rotating (Paddle + Anchor) MATERIAL OF CONSTRUCTION Carbon Steel Carbon Steel + FRP Carbon Steel + PVC Carbon Steel + Rubber Lined Carbon Steel + Epoxy Coating Stainless Steel ( SS 304, SS 304L, SS 316, SS 316L) Special Alloys. Haste alloy Titanium MOUNTING ARRANGEMENT Foot mounted Motor with Gear Box Flanged mounted Geared Motor With and Without Bottom Bush Wall mounted Side entry with retracting type Mechanical Seal Chain / Hoist mounted Portable clamp mounting Detachable coupling

...more

Eductor Mixers

Eductors utilize Kinetic Energy of one Liquid to pull another mix with it and convey it further up. The high pressure of one pump is converted into the Kinetic Energy and high velocities. The suction caused thereby pulls the other Liquids for the the further action There are several uses of Eductors such as: Line Mixing Eductors (LME). Mixing with Solids to form Slurries. Sump Eductors. Water Jet Vacuum Pump LME’s are used for suction of Gas to form small Bubbles in Gas Liquid operations. They are useful when one Liquid is available at high pressure and it has to mix with another which is without a pump or having a low discharge pressure pump

...more

Line Mixing Eductors

Line Mixing Eductors are used to prepare hot water with use of low pressure steam.

...more

Flow Meters

Flow Meters for Viscous and Non-Newtonian Liquids The principle on which the design is based is elaborated in a short Article which is attached. For a given Liquid and given range of Flow rates, we shall design a flow meter for your use. Please let us know the operating temperature and physical properties of your Liquid.

...more

Inline Homogeniser Mixer

Inline Homogenizer (Static / Rotating) Inline Homogenizer (Static / Rotating) The term ‘Homogenizer’ is used for high pressure drop devices, where pressure of 200 to 600 bar are generated across a ‘Cavity’. These are predominantly used in Dairy Industry. ‘Homogenization’ – generally means any material (Liquid or Paste) that has the same properties (Density or Viscosity) in its entire ‘body’. Any material that does not possess such properties is ‘In-Homogeneous’. You need to ‘churn’ it, mix it or blend it together to make it homogeneous. We have two products for this application: Inline Homogenizer (Static) and Inline Homogenizer (Rotating) Inline Homogenizer (Static) There are ‘No moving parts’ here. The ‘Energy’ for Mixing is provided by pump that has to pump the material through these ‘Mixers’ where it is cut, churned, blended and mixed and pushed further. The ‘Pressure Drop’ depends upon the ‘Viscosity’ of the material and the temperature. Inline Homogenizer (Rotating) Here ’Energy’ is given by a ‘Motor’ which is attached to the ‘Rotator’. ‘Motor HP’ depends upon the viscosity of the material and the temperature. Material of Construction is generally SS304 or SS316. Depending upon the chemical properties of the Liquid MOC shall be suggested.

...more

Scraped Surface Heat Exchanger

A unique Scraped Surface Heat Exchanger specifically designed for processing thick, high viscosity materials and heat exchanging a variety of specially heat sensitive products like fruit pulps of mangoes, papayas, guavas, peaches and juice concentrates. The continuous scraping action exerted on the heat transfer surface ensure uniform heating of the contents, prevents product fouling/burn-out. It is also heavily used for materials that solidify at the wall temperatures. The Rotary Scraped Surface Heat Exchanger consists of a stainless steel tube, suitably jacketed in a carbon steel jacket insulated from outside and covered with stainless steel sheathing. The stainless steel centre shaft of the heat exchanger is fitted with Teflon scrapers which scrape the internal surface of the heat exchanger continuously. The positive displacement pump ensures constant product in feed. Cleaning procedures are simple and easy at the end of a run, without need to dismantle the product contact parts for inspection. The unit is complete with motor and necessary fittings. Optional extras include starter, temperature controller and recorder, and automatic product flow control. Depending upon the capacity requirement, multiple units can be supplied in series or parallel working arrangement. The unit can also be used as an efficient product cooler, by using a suitable coolant. With appropriate modifications such as addition of necessary flash chamber, barometric/semi-barometric condenser with vacuum pump, etc., the heat exchanger can also be used as a thin film evaporator mainly for concentration of thick, viscous, delicate and heat sensitive products. Single effect/double effect evaporator may also be offered for concentration of viscous or heat-sensitive products which are otherwise difficult to be concentrated by other conventional means. 500 to 10,000 liters per hour. Depending on the objective and viscosity of product and process requirement Electric Power will be calculated for each application

...moreBe first to Rate

Rate ThisOpening Hours