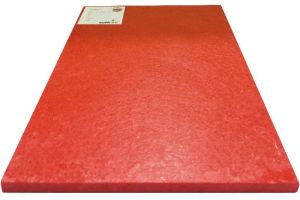

Mat Glass Reinforced Polyester

GPO-3 is a general purpose grade Random Weave Glass Polyester Laminate. It is composed of random mat (non-woven) fiberglass reinforcement held together by a polyester resin binder. GPO3 composite sheet offers arc and track resistance. It is malleable, and can be made into various shapes like sheets, tubes, rods, etc. Properties of GPO3 Fiberglass Laminate Tufflam® GPO-3 composites have high dielectric strength, high flexural strength, high impact strength, flame resistance, as well as arc and track resistance. Despite all these appreciable qualities, Tufflam® GPO-3 glass polyester is a low-cost laminate. It can withstand higher temperatures than GPO-1 or GPO-2, and has better electrical characteristics than them, as it is more flame-resistant than GPO-1, and more arc-and-track resistant than GPO-2. Applications of GPO3 Polyester Laminate include general purpose electrical insulation, Transformer Spacers, Transformer Supports, Transportation Components, Track Resistance, Terminal Boards and Tag Strips, Switchgears, Switchgear Link Bars, Punched Components, Phase Barriers, Busbar Supports, Mechanical Applications, Insulating Bushes, Spacers and Sleeves, Insulation for High Voltage Appliances, High Voltage (Oil submerged) appliances, High Temperature Components, Flame Retardant Applications, Chemical Resistance Components, etc. SAM Associates offers a wide range of polyester sheets of different grades and specifications, with high precision thickness and durability. To learn more about our offerings,

...more

glass epoxy laminates

G-10 (named after the NEMA grade of the same name) is a fiberglass laminate composite material that was first introduced in the 1950s. It is an electrical insulator of high tensile strength meant to withstand high pressure. NEMA G10 is defined as being a combination of continuous filament-type glass cloth with epoxy resin binder. G-10 sheets are usually a few millimeters thick. TUFFLAM G10 materials are available in various thicknesses from 0.5mm to 70mm. Our G-10 Glass Epoxy Sheets are used in a variety of applications. G-10 manufacturing The manufacturing of G-10 is similar to standard phenolic and carbon fiber laminates. Tufflam® G-10 is produced by either Wet Laminate process or by Prepreg process. As no filler is used during the manufacture of Tufflam® G-10, the manufacturing results in a natural green colour (or natural yellow, depending on the type of resin used). Properties of G-10 Laminates G-10 has a high mechanical strength, good insulation resistance, dielectric loss, and dielectric strength under dry and humid conditions”. G-10 is also impervious to liquids like water and kerosene. When faced with economic constraints, phenolic resin and/or fillers may be used. Such phenolic/impure G-10 laminates are ideal for lower temperature classes, but fail when continuously used at elevated temperatures. Pure G-10 fiberglass epoxy composite, on the other hand, can easily overcome these problems, offer superior electrical and mechanical properties, and also work consistently at temperatures like 155° and 180° C. G-10 can also attain flame-retardant properties via processes like bromination. Flame-retardant G-10 is often called as FR-4 insulation. G-10 Designs and Customizations Decorative variations of G-10 can be produced in many patterns and colours. Such customized designs are used to make handles for knives, grips for firearms, etc. These can be textured (for grip), bead blasted, sanded or polished. G-10 also finds use in windsurfing, as it is resistant to impacts. NEMA G-10 is usually preferred in its natural green, natural yellow or black colours. Other custom coloured laminates can be prepared by introducing pigments of the desired colour during the manufacturing process. At SAM Associates, we manufacture G-10 glass epoxy laminate sheets and products, custom-fabricated to cater to the specifications and needs of every client. To know more about this thermoset rigid laminate, or to receive our lowest quotations, press the button

...more

Fibre Glass Sheets

Frp Electric Insulation Material

Brominated Glass Epoxy Laminate

Tufflam® FR-5 is the brominated, flame-retardant version of G-11 glass epoxy laminate. In properties, it is more flame-retardant than G-11, has a higher operating temperature, and additionally has superior mechanical properties both in dry and humid conditions. Thus, FR-5 comes with very high mechanical and electrical strength even at elevated temperatures. It has good electric strength, dielectric loss and chemical resistance. It is flame retardant, and absorbs very little water. The FR-5 composite can be used in every application where G-11 is used, but the latter is not possible. FR-5 is considered ideal for Multilayer PCBs (with high number of layers), PCB holders, Antennal Isolators, Isolators in other electrical and electronic circuits, Test Boards, End Plates, Solder Frames, as well as miscellaneous applications in the automotive Industry. At Tufflam®, we offer a very high quality of FR-5 laminates. To know more about this product, or to order this product in bulk or samples, kindly fill the form below.

...more

High Temperature Laminate

Tufflam® P7000 is a high temperature glass polyester laminate similar to Tufflam® P5000. It is constructed from a chopped strand mat woven fabric with a synthetic resin binder. The Synthetic resin system is not flame retardant, but has greater temperature resistance than epoxy/polymer grade laminates. The maximum service temperature of Tufflam® P7000 is 270° C / 518° F. Tufflam® P7000 is generally used in electrical and electronic insulation where low moisture absorption, good chemical resistance, and very high physical strength is needed. It is, however, not recommended for wear applications. To learn more about this product, or to request samples/quotations, kindly fill the form below.

...more

paper phenolic laminates

What are Paper Phenolic Laminates? Paper Phenolic Laminates are composite laminates that are produced with Kraft paper and phenolic resin. They are well-suited for mechanical and electrical applications meeting international standards. Tufflam® provides Paper Phenolic Laminates of 4 types, viz. P-1, P-2, P-3 and P-4, conforming to NEMA grades X, XP, XX, XXP and XXXP. Types of Paper Phenolic Laminates Tufflam® P-1 laminates conform to NEMA grade X and grade XP. Grade X Paper Phenolic is a paper-based high pressure laminate. It has the highest flexural strength of the paper-based phenolic group. This material is primarily intended for mechanical application where electrical properties are of secondary importance. Nema XX is the grade assigned by NEMA to general purpose Paper Phenolic Laminates. Tufflam® P-2 laminates confer to NEMA grade XX. Although they are not as hot-punchable as grades like XP and XXP, these are certainly applicable for a number of mechanical applications. NEMA XX is a good electrical insulator with fair mechanical strength. It can be used in dry or humid conditions for switchboard panels, relay and switch bases, breaker arms and barriers. NEMA XXP grade, sold as Tufflam® P-3, is similar to XX, but possesses greater shear strength, and maximal impact strength among all the paper phenolic laminates. It offers high insulation resistance, and absorbs much lesser water than XX or XP. NEMA XXXP grade is the last paper phenolic grade assigned by NEMA for which Tufflam® offers paper phenolic laminates. Tufflam® P-4, as NEMA XXXP is called, offers the highest shear strength and insulation resistance among paper phenolic laminates. It offers very low water absorption. It is ideal for punching of parts that require high insulation resistance at high frequencies and high humidity. XXXP should be punched hot.

...more

Phenolic Canvas Cotton Cloth Laminates

Tufflam® manufactures the following range of phenolic canvas cotton cloth laminates: Tufflam® F-2 A mechanical grade of fine weave cotton cloth laminate impregnated and cured with phenolic resin. Its grade is NEMA L. F2 is a high mechanical strength laminate used in making fine tooth gears, terminal boards and in electronic parts. Tufflam® F-3 A mechanical grade of medium weave cotton cloth laminate impregnated and cured with phenolic resin. Its grade is NEMA C. F3 is an economy grade mechanical laminate that possesses high impact strength. It is used for gears, pinions, bearings, bushings and many other structural applications. Tufflam® F-4 A mechanical/electrical grade of medium weave cotton cloth laminate impregnated and cured with phenolic resin. Its grade is NEMA CE. It is an economy grade mechanical/electrical insulation that possesses good low frequency, low voltage electrical performance. It is used for gears, pinions, bearings, bushings, electronic parts and marine switchboard panels. Tufflam® F-5 A mechanical/electrical grade of fine weave cotton cloth laminate impregnated and cured with phenolic resin. Its grade is NEMA LE. It is a moisture resistant, high mechanical strength electric insulator used as a marine relay bases, terminal bases, terminal strips and in electronic parts.

...moreBe first to Rate

Rate ThisOpening Hours