Mass Mixer

Get Price Quote

• Ideal For Mixing Dry & Wet Material. • Paddles Type Blades So Arranged On The Shaft To Give Through Uniform Mixing Of Thick Heavy Material. • The Drive System Is Through Suitable Worm Gear And Motor. • Provision For Tilting Arrangement , Reversible Switch And Safety Lock-switch To Stop The Mixer As Soon The Cover Is Opened. • PTFE Gland Mechanism Provided at Shaft ends to Prevent Inner Leakage. • The Mass Mixer Is Also Provided With A Lever With Hand Wheel To Accomplish Tilting Manually.

Mass Mixer

Get Price Quote

SUITABLE FOR MIXING WET AND DRY POWDERS PADDLE TYPE BLADES PROVIDED WITH LEAK PROOF SEAL TILTING ARRANGEMENT, LIMIT SWITCH WITH S.S. GRILL S.S. 304 316 QUALITY AND MIRROR POLISHED UNIT WITH SUITABLE MOTOR AND GEAR BOX MANUAL TILTING ARRANGEMENT MODEL 25, 50, 100, 200 & 250 Kgs. CGMP MODEL WITH DOCUMENTATION (IQ, DQ, PQ, OQ) - AS OPTION

Best Deals from Mass Mixer Machine

Mass Mixer

Get Price Quote

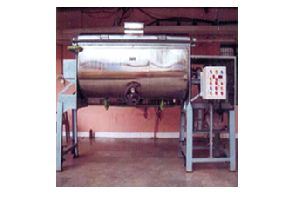

The Mixer consists of mixing drum complete in itself. It contains a mixing drum body, mixing paddle and sealing arrangement. The drum rests on rigid M.S. fabricated body carrying motor, gear box, starter and tilting arrangement. The drive of mixing paddle is through suitable oil filled worm gear unit which in turn gets drive through V belts from a suitable T.E.F.C. motor. The blades of the paddle are so arranged that thorough mixing is obtained. All parts which are in direct contact with the material to be mixed are of S.S. or neutral material. The main paddle runs in journals and supported by thrust bearings of ample size to carry rigid and thrust load. The whole drum of the mixer makes for ease of cleaning. The rotor is so designed that it can be removed by removing the main shaft without much problem. ADDITIONAL FEATURES: • Plastic Dust Cover provided to see the process all the times. • Safety : If motor covers open it will trop off automatically. • Tilting Device is provided to ease the unloading of the material Specially designed self-adjusting sealing arrangement Provision is made for lubricating all moving parts

Mass Mixer

Get Price Quote

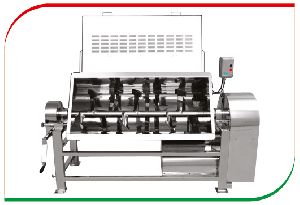

General Specification: Shell : Consisting of ‘U’ trough of suitable dimensions. Construction of S.S and side plates duly M.S stiffened from outside and from inside with S.S. Mixing Mechanism : Paddle type blades welded to the main shaft provide for efficient mixing of thick heavy material. PTFE gland mechanism provided at shaft ends prevents ingress of external powder into the trough and prevents leakage. Charging : From the top charging can be done through hingeable lid, Hopper or Nozzle can be provided for additional spraying of additives. Discharge : By bottom discharge slide Iris or Butterfly valve of suitable diameter, for regulated discharge. Drive : Consisting of suitable HP TEFC 3 phase ac 415v / 50 cycles motor coupled to suitable worm gear, with driving shafts mounted on suitable plummer block. Mounting : Mounted on suitable ISMC Section Stand, with protective covers for belts and couplings. MOC : All contact parts in S.S construction. Complete unit with S.S. cover and all surfaces polished to mirror dull finish. MS parts dull painted to smooth finish. Options Available : The control panel is mounted on platform and is provided. 1.

Mass Mixer

Get Price Quote

SALIENT FEATURES * All contact parts are made out of S.S.304316M.S quality material. * Compact design requires comparatively smaller floor space. * Single blade with single speed for dry & wet mixing. * Proper sealings arrangement is provided to eliminate any black particle contamination problem, leakage, wear & tear. * All moving parts are enclosed with safety guards.

Mass Mixer

Get Price Quote

Mass Mixer Machine

Get Price Quote

1 Piece (MOQ)

Mass Mixer

Get Price Quote

Mass Mixer, Coating Pan, Multi Mill, Polishing Pan, tanks vessels

Mass Mixer Machine

Get Price Quote

Sigma Mixer Machine, Flaker machine, Octagonal Blender, Paddle Mixer