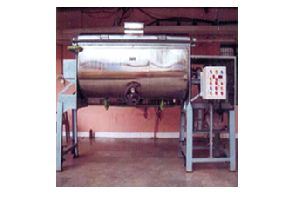

Powder Mass Mixer

Get Price Quote

Feature: Capacity Volume Motor

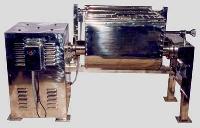

Mass Mixer

Get Price Quote

Best Deals from Mass Mixer Machine

Mass Mixer

Get Price Quote

cGMP The Mass Mixer is an efficient and versatile blending machine for mixing of dry granules & powders homogeneously. This Ribbon Blender gives best result for mixing of dry powder & granules due to the design and shape of the mixing ribbon and product container. Salient features : Effective mixing of dry or wet materials of Tablet Granualtion, Powder Mixing, Chemicals, Food, Confectioary etc. Machine rated for continous operation. Conventional efficient mixing through paddle type blades welded to the main shaft horizontally mounted in the container & has a single speed and simple rotation. All contact parts of AISI SS 316 & SS 304(optional) East to clean and operate. In compliance with cGMP guidelines. Interlocking system at top cover is provided to avoid the accident Flame proof electrical can beprovided with extra cost. Capacity available in 50kg to 500kg.

Mass Mixer

Get Price Quote

Mass Mixer has been well-designed to facilitate thorough mixing of dry or damp materials and is especially suitable for tablet granulation. The powerful geared drive and sturdy mixing paddle make MassMixer ideal for dealing with difficult or sticky ingredients. This is one speed Mixer but two speed machine available on demand.

Mass Mixer

Get Price Quote

General Specification: Shell : Consisting of ‘U’ trough of suitable dimensions. Construction of S.S and side plates duly M.S stiffened from outside and from inside with S.S. Mixing Mechanism : Paddle type blades welded to the main shaft provide for efficient mixing of thick heavy material. PTFE gland mechanism provided at shaft ends prevents ingress of external powder into the trough and prevents leakage. Charging : From the top charging can be done through hingeable lid, Hopper or Nozzle can be provided for additional spraying of additives. Discharge : By bottom discharge slide Iris or Butterfly valve of suitable diameter, for regulated discharge. Drive : Consisting of suitable HP TEFC 3 phase ac 415v / 50 cycles motor coupled to suitable worm gear, with driving shafts mounted on suitable plummer block. Mounting : Mounted on suitable ISMC Section Stand, with protective covers for belts and couplings. MOC : All contact parts in S.S construction. Complete unit with S.S. cover and all surfaces polished to mirror dull finish. MS parts dull painted to smooth finish. Options Available : The control panel is mounted on platform and is provided. 1.

Mass Mixer Machine

280,000 Per Piece

1 Piece(s) (MOQ)

Mass Mixer

Get Price Quote

The Mixer consists of mixing drum complete in itself. It contains a mixing drum body, mixing paddle and sealing arrangement. The drum rests on rigid M.S. fabricated body carrying motor, gear box, starter and tilting arrangement. The drive of mixing paddle is through suitable oil filled worm gear unit which in turn gets drive through V belts from a suitable T.E.F.C. motor. The blades of the paddle are so arranged that thorough mixing is obtained. All parts which are in direct contact with the material to be mixed are of S.S. or neutral material. The main paddle runs in journals and supported by thrust bearings of ample size to carry rigid and thrust load. The whole drum of the mixer makes for ease of cleaning. The rotor is so designed that it can be removed by removing the main shaft without much problem. ADDITIONAL FEATURES: • Plastic Dust Cover provided to see the process all the times. • Safety : If motor covers open it will trop off automatically. • Tilting Device is provided to ease the unloading of the material Specially designed self-adjusting sealing arrangement Provision is made for lubricating all moving parts

Mass Mixer

Get Price Quote

Suitable for mixing of dry/wet material All contact parts in AISI SS 316/ 304 Efficient & uniform mixing Tilting arrangement, reversible switch and safety switch provided Capacities range from 50 kgs to 500 kgs per batch cGMP Construction With High Pharmaceutical Finish With Documentation

Mass Mixer

Get Price Quote

Customers should not worry about the security of their payments with us as we follow secured Online and Offline Payment Processing. By making use of quality packaging material, we pack the entire lot in a safe manner ensuring zero damage at buyer's end. The packing procedure is conducted under the guidance of experts.

Mass Mixer

150,000 Per Piece

Mass Mixer

Get Price Quote

SUITABLE FOR MIXING WET AND DRY POWDERS PADDLE TYPE BLADES PROVIDED WITH LEAK PROOF SEAL TILTING ARRANGEMENT, LIMIT SWITCH WITH S.S. GRILL S.S. 304 316 QUALITY AND MIRROR POLISHED UNIT WITH SUITABLE MOTOR AND GEAR BOX MANUAL TILTING ARRANGEMENT MODEL 25, 50, 100, 200 & 250 Kgs. CGMP MODEL WITH DOCUMENTATION (IQ, DQ, PQ, OQ) - AS OPTION

Mass Mixer

Get Price Quote

DESCRIPTION Design as per stringent cGMP requirements Uniform mixing All contact parts SS 316 Tilting device for easy unloading and cleaning

Mass Mixer

Get Price Quote

SALIENT FEATURES * All contact parts are made out of S.S.304316M.S quality material. * Compact design requires comparatively smaller floor space. * Single blade with single speed for dry & wet mixing. * Proper sealings arrangement is provided to eliminate any black particle contamination problem, leakage, wear & tear. * All moving parts are enclosed with safety guards.

Powder Mass Mixer

Get Price Quote

Features Suitable for mixing of dry & wet material All contact parts in stainless steel Paddles so arranged on the shaft to give thorough uniform mixing Tilting arrangement, reversible switch and safety switch to stop the Mixer as soon as the cover is opened The drive is through a system of suitable gear-box and motor

Powder Mass Mixer

Get Price Quote

Salient Features :Well-designed to facilitate through mixing & Ease in cleaning.Safety Plastic Dust cover provided with inter locking system, safety device in a way stick that on opening of the cover the machine stop functioning. Tilting device Is provided for ease in unloading by means of Handle wheel.Specially designed self-adjusting sealing arrangement to ensure no black particles enter into the mixing drum.

Mass Mixer Machine

Get Price Quote

1 Piece (MOQ)

Mass Mixer

12,500 Per Piece

Mass Mixer

Get Price Quote

We are delivering a wide range of Mass Mixer to our highly valued clients. These are used for assimilating wet & dry or bulge material with easy operating system and full fledge working capacity known as the stainless steel mass mixer, as per the customer’s requirement. Our products are easily procurable at very low market prices. SALIENT FEATURES : In compliance with cGMP guidelines. Also available with Standard Painted Model. Conventional efficient mixing through paddle type blades welded to the main shaft horizontally mounted in the container & has single speed, simple rotation. All contact parts of AISI stainless steel 304 material. AISI stainless steel 316 quality contact parts optional. Easy for cleaning and operating. Safety Plastic dust cover provided for apparently seeing the mixing process. Interlocking system at plastic dust cover is provided to avoid the accident. The tilting device provided by means of hand wheel (manually operated) for easy unloading of the material. Specially designed self-adjusting sealing arrangements to ensure no black particle enter into the mixing drum. Models for Small Scale, Laboratory (Research Purpose) Capacity, as per customize requirement are also available. Flame proof electrical can be provided with extra cost. Efficient for mixing of dry or wet materials of Tablet Granulation, Powder Mixing, Chemical, Food, Confectionary etc.

Mass Mixer

Get Price Quote

We are an exclusive member amongst the frontline Pharmaceutical Equipment Manufacturers from India. The use of excellent quality materials in the manufacturing of the Pharmaceutical Processing Equipment ensures high durability and resistance to adverse conditions. The unmatched quality and unsurpassable performance has also made the Pharmaceutical Processing Equipment ideal choice of customers. Additionally, customers are eased with the availability of the advanced Pharmaceutical Equipment at the most nominal prices.

Mass Mixer

Get Price Quote

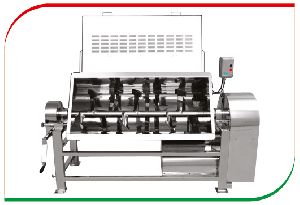

Mass Mixer Machine

Get Price Quote

Mass Mixer

Get Price Quote

We offer mass mixer with following features: SHELL: Consisting of ‘U’ trough of suitable dimensions. Construction of S.S. and side plates duly M.S./S.S. stiffened from outside and from inside with S.S. MIXING MECHANISM: Paddle type blades welded to the main shaft provide for efficient mixing of thick heavy material. PTFE gland mechanism provided at shaft ends prevents ingress of external powder into the trough and prevents leakage. CHARGING: From the top charging can be done through a hinge able lid, hopper or Nozzle can be provided for additional spraying of additives. DISCHARGE: By bottom discharge slide Iris or Butterfly valve of suitable diameter, for regulated discharge. DRIVE: Consisting of suitable H.P. TEFC 3 phase ac 415v / 50 cycles motor coupled to suitable worm gear, with driving shafts mounted on suitable Plummer block. MOUNTING: Mounted on suitable ISMC Section Stand, with protective covers for belts and couplings. MOC : All contact parts in S.S. Constructions. Complete unit with S.S. cover and all surfaces polished to mirror dull finish. MS parts dull painted to smooth finish. Recent Products For Complete Product List Click Here

Mass Mixer

Get Price Quote

Mass Mixer has been well-designed to facilitate thorough mixing of dry / damp powders & Granules and is especially suitable for granulation. The powerful geared drive and sturdy mixing paddle makes Mass Mixer ideal for mixing with all kind of products in various applications Manual Tilting mechanism is provided for discharging. Lid is provided with product charging facility interlocked with main drive to ensure operator safety Optional : Available in STD/GMP models Construction SS 304 / 316 / 316L Motorized tilting for discharge Variable Speed drive optional Flame proof motor, push button station and limit switch. Control panel with timer.

mass mixers

Get Price Quote

The Mass Mixer is used for mixing dry or dump materials and used for tablet granulation consisting of ‘U’ trough of suitable dimensions. Construction of S.S. and side plates duly M.S. stiffened from outside and from inside with S.S. paddle type blades welded to the main shaft provide for efficient mixing thick heavy material. PTFE gland mechanism provided at shaft ends prevents ingress of external powder into the trough and prevents leakage. From the top charging can be done through a hinge able lid, hopper or Nozzle can be provided for additional spraying of additives. Bottom discharge slides Iris or Butterfly valve of suitable diameter, for regulated discharged. Consisting of suitable H.P.TEFC3 phase ac 415v/50 cycles motor coupled t suitable worm gear, with driving shafts.

Mass Mixer

Get Price Quote

• Ideal For Mixing Dry & Wet Material. • Paddles Type Blades So Arranged On The Shaft To Give Through Uniform Mixing Of Thick Heavy Material. • The Drive System Is Through Suitable Worm Gear And Motor. • Provision For Tilting Arrangement , Reversible Switch And Safety Lock-switch To Stop The Mixer As Soon The Cover Is Opened. • PTFE Gland Mechanism Provided at Shaft ends to Prevent Inner Leakage. • The Mass Mixer Is Also Provided With A Lever With Hand Wheel To Accomplish Tilting Manually.

Mass Mixer

Get Price Quote

Mass Mixer

Get Price Quote

Mass mixer is efficient to be used for mixing dry and damp material. It is ideal for tablet granulation. Vessel is fitted with dust cover so that black particles cannot enter into it, make it safe for use. Salient Features : Standard and GMP model with contact parts in SS 304/ SS 316 quality. Specially designed flush type outlet valve or butterfly valve (optional). Top cover with acrylic sheet. The cover is connected to limit switch for the safety purpose. Machine automatically stops as soon as the cover is opened during the operation for the safety of operator. Shaft sealing at inside and out side with teflon bush and SS stuffing box at outside. Solid stainless steel end covers and frame work on the trough in even standard models for long trouble free life of the machine. Features : Suitable for mixing wet and dry powders. Paddle type blades. Provided with leak proof seal tilting arrangement, limit switch with s.s. Grill. S.S 304 / 316 quality and mirror polished unit with suitable motor and gear box. Manual tilting arrangement model 25, 50, 100, 200 and 250 kgs. CGMP model with documentation (iq, dq, pq, oq) - as option.

Mass Mixer

Get Price Quote

SALIENT FEATURES: Well designed to facilitate through mixing & Ease in Cleaning. Safety Plastic Dust cover provided with inter locking system, safety device in a way such that on opening of the cover the machine stop functioning. Tilting device is provided for ease in unloading by means of Handle wheel. Specially designed self-adjusting sealing arrangement to ensure no black particles enter into the mixing drum.

Mass Mixer

Get Price Quote

We are offering mass mixer. we are instrumental in offering the most durable range of mass mixer to the clients. Our mass mixer is manufactured from high quality components ensuring international quality standards. This mass mixer is widely appreciated for its features like durability, resistance to corrosion, strong construction and leak proof design. Mass mixer offered by us is effectively checked by quality inspectors on several parameters before supplying in the market. We also offer customized range of mass mixers as per the requirement of the client. working of the mass mixer mixing mechanism : paddle type blades welded to the main shaft provide for efficient mixing of thick heavy material. Ptfe gland mechanism provided at shaft ends prevents ingress of external powder into the trough and prevents leakage.charging : from the top charging can be done through a hinge able lid, hopper or nozzle can be provided for additional spraying of additivesdischarge : by bottom discharge slide iris or butterfly valve of suitable diameter, for regulated discharge construction of mass mixer shell : consist of 'u' trough of suitable dimensions. Construction of s.s. And side plates duly m.s. Stiffened from outside and from inside with s.s.drive : consist of suitable h.p. Tefc 3 phase ac 415v / 50 cycles motor coupled to suitable worm gear, with driving shafts mounted on suitable plummer blockmounting : mounted on suitable ismc section stand, with protective covers for belts and couplingmoc : all contact parts in s.s. Constructions. Complete unit with s.s. Cover and all surfaces polished to mirror dull finish.available inunit with flpunit in s.s. 316gmp model with m.s. Parts cladded with s.s

mass mixers

190,000 Per Piece