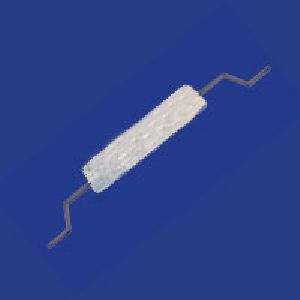

Copper Bonded Electrodes

Get Price Quote

Another variety that we present to you is Copper Bonded Electrodes! As a quality driven firm, we make them using quality tested raw material and advanced production techniques. We are well-reckoned Manufacturer, Exporter & Supplier of Copper Bonded Electrodes in Maharashtra, India. Further, we make due consideration on the packaging to ensure hassle free shipment.

Welding Electrodes

Get Price Quote

The company stands tall among the successful Suppliers of Welding Electrodes from Mumbai, Maharashtra. The Welding Electrodes offered by us is manufactured in compliance with set industrial norms. We maintain a large stock of the Welding Electrodes in our state-of-the-art warehouse, to meet the bulk and urgent requirements of the buyers. We are capable in delivering any order of Welding Electrodes to the buyers all over the country.

Best Deals from Medical Electrode

Welding Electrode

Get Price Quote

We are offering welding electrode. We would like to introduce ourselves as a one of the leading importer & stockiest of all kind of stainless steel ,nickel base alloy, titanium alloys, in filler wires, flux cored wire, welding electrodes etc in india. We can offer you all the material ex-stock mumbai at most competitive rates along with canvet benefit & batch test certificate of many brands such as nihonweld,tigweld arc,oxford alloys, arcos usa, gee ltd, esab, d&h secheron, ador etc cobalt base alloys :- welding electrodes : grade 1, grade 6, grade 12, grade 21 filler wire : grade 1, grade 6, grade 12, grade 21 stainless steel :- welding electrodes : e308, e308l-15, e308l-16, e-308l-17, e316, e316l-15, ,e316l-15, e309, e309l, e309mol, e385, e310, e347, e2209, e2553 filler wires : er308l, er308h, er316l, er316h, er309l, er309lmo, er310, er318, er310lmo, er904l, er 317l, er385 flux cord wire : e308lt-i, e316lt-i, e309lt-i, e347lt-i, e309lmot-1 nickel base alloys :- welding electrodes : nickel 141, monel 190, monel 187, inconel 62, inconel 182, inconel 117, inconel 112, incoweld a, hastalloy c-276, etc. filler wire : nickel 61, inconel 52, inconel 82, inconel 92, monel 60, monel 67, inconel 625, inconel 617, inconel 718, hastalloy c-276, titanium base alloys :- filler wires : grade 1, grade 2, grade 5, grade 12 aluminium wire :- : er4043, er5356 etc

Stainless Steel Electrode

450 - 500 Per Pack

COPPER ANODES and NUGGETS

Get Price Quote

We manufacture Copper Anodes/Nuggets from genuine copper cathode. They are highly used for decorative, rotogravure and printing circuitry. It is also used in Electrical ground rod and other functional plating applications. We provide Copper Anodes that are in different size and shapes having different levels of phosphorous. Our Copper Anodes provides good control and reliable performance. Copper Anodes that we manufacture are by far the best in the market with the finest reliability and dependability.

Zinc Hull Anode

Get Price Quote

Our organization is the prominent name in involved in offering an attractive range of zinc hull anode to our valuable clients. These products are designed to prevent corrosion of the entire immersed steel hull area, which includes exposed shafts, brackets, rudders and propellers. Our customers can utilize all these products according to their choice and requirements. mentioned are the attributes: high conductivity excellent performance corrosion-resistance longer functionality easy installation.

Cathodic Protection Anodes

Get Price Quote

Zinc Tank Anodes

Get Price Quote

Zinc Tank anodes are used to complement the coating at areas of exposed steel prolonging the life of the coating and structure. Hydrogen is evolved from zinc anodes and thermite sparking may occur when light alloys impact on rusty steel. Therefore there is a height restriction in cargo/ballast tanks in tankers that anodes are not located at a height (in m) greater than 27/W where W is the total mass (in kg) of the anode and insert.

brass welding rod

Get Price Quote

We are the main supplier of this product.

Welding Rods

Get Price Quote

Astsiddhi Metal offer superior quality welding rods that is manufactured using best quality metals and latest machines as per the international quality standards. this is extensively demanded by our valuable clients for structural, mechanical and heavy duty applications. Our welding rods is widely known for their high strength and durability. This range is mostly used in pipe welding in various industries.

Pinnacle Alloy ENiCrFe-3 Welding Electrode

2,200 Per

100 Kilogram (MOQ)

Stainless Steel Filler Wire

250 - 450 Per Piece

50 Kilogram (MOQ)

Oxygen Free Copper Anode

445 Per Kilogram

Product Description:Phosphorous Copper Anode (Cu-DHP) finds usage in the plating of Printed Circuit Boards. These anodes are available in Copper Ingots, Copper Cathodes and Electrolytic Copper options with all copper forms containing in it least 99.9% copper. Free from impurities, these provide the safeguard from contamination of electroplating solutions as well as a Co deposit on the cathode. Further, these are also available in suitable metallurgical condition to dissolve uniformly.General Specifications: Size - Oval - 80mm x 30mm; Ball minuscule 25mm, minuscule 38mm, minuscule 50mm or as per customer requirement Material Standard- ASTM B265, Grade 5, Grade 9 Shape- Oval, Ball Weight - per foot Application Areas: Electroplating Applications Rotogravure Electroforming Decorative Printed Circuitry Electrical Ground Rod Electro-forming Other functional plating applications. Jans Copper Pvt Ltd is one of the leading Copper Anodes, Copper Balls & Copper Nuggets manufacturer and supplier in India. Jans Copper Pvt Ltd's Copper Anodes, Copper Balls & Copper Nuggets are manufactured in accordance with the defined international standards. The raw material that is used to manufacture SIMCO copper products are LME grade ‘A’ cathodes of purity greater than 99.99% copper resulting in higher conductivity, crack free extrusion, excellent finish and longer life. Available Sizes As per customer’s requirement Available Grades ETP, OFC, Phosphorised Copper Plating / Coating Bare Additional Specifications / Details Available in all forms i.e. Oval, Slabs, Balls, Rods, Nuggets, etc. Applications / Uses Printed circuit boards, Rotogravure, Electroforming, etc. Overall, there are several characteristics that determine the quality of the copper anodes manufacturing process. These include: purity of copper, fine grain structure, uniform phosphorus content and distribution, and properly cleaned and anodes packaged and ready for use. Therefore, the quality of copper anodes should be very important to electroplaters because properly manufactured anodes will: extend bath life; have less metallic contamination; produce parts without roughness; have less sludge; and require less maintenance.

Stainless steel earthing Rod

Get Price Quote

Capable of catering to the varied demands of the customers, we are named amidst the respected Suppliers of Stainless Steel Earthing Rod. We are capable of delivering the bulk consignments of the clientele effortlessly as we have excellent storage facilities. We have segregated units in the warehouse that helps us in delivering all the products systematically. Details : Nexus stainless steel ground rods are used to overcome many of the problems caused bygalvanic corrosion which can tabke place between dissimilar metals buried in close procximity. Other advantages of stainless steel rod are that they are highly resistant to corrosion are muchmore anodic than copper.

lead anodes

Get Price Quote

2 Ton (MOQ)

HMS Metal Corporation is a Leader in the production and Supply of Anodes used in copper, zinc and nickel refining. Our electrowinning anodes integrate years of experience, research and development.With fully Integrated & 100% in-house production facility we are able to Internally controlled workmanship for alloying, rolling blade, head bar tinning and casting, welding, cutting & packaging. Although anodes are manufactured to client’s designs, with each stage of manufacture using the best quality raw materials and controlled by a strict quality process system, anodes are produced efficiently and consistently within estimated time. Anodes made of lead alloys are used in the electrowinning and plating of metals such as manganese, copper, nickel, and zinc. Rolled lead-calcium-tin and lead antimony alloys are the preferred anode materials in these applications, because of their high resistance to corrosion in the sulfuric acid used in electrolytic solutions. Lead anodes also have high resistance to corrosion by seawater, making them economical to use in systems for the cathodic protection of ships and offshore rigs. Rolled lead anodes have become the industry benchmark with the benefits of fine grain structure, less segregation and elimination of cracks and voids resulting in more uniform corrosion of the anode. The shape and size of the copper bar and the anode plate are made to customer specifications The copper bar is tin-plated and then given a homogeneous coat of lead several millimeters thick as protection from corrosion caused by aggressive acid mist. This method of protecting the anode bar also ensures the best possible bond between lead and copper for improved current flow and long service life. Chemical Composition The lead anodes are manufactured in calcium-tin-lead (Ca/Sn/Pb), antimonial lead (Sb/Pb) and silver-lead (Ag/Pb) alloys which are the preferred alloys for these applications with their high resistance to corrosion in the sulphuric acid based electrolyte solutions. Lead anode alloys generally consist of tin, Calcium, and Antimony. The favoured alloys, based on the specific application, are lead- antimony as well as lead-Calcium-Tin alloys. One reason for this is because of the alloys’ resistance to corrosion in the sulfuric acid that’s used for electrolytic solutions. (Lead-alloy anodes are used in electro winning – also known as electro extraction – as well as for plating metals such as manganese, copper, nickel, and zinc.) Lead anodes have superior attributes, such as being highly resistant to the corrosive effects of seawater. We also offer custom Lead Alloys to meet your specifications We specialize in manufacturing complete Lead Anode and Anode Plates for Zinc, Nickel and Copper extraction electrolysis plant. Electrowinning of copper, nickel, cobalt and zinc in SX-EW processing of ores. Ca/Sn/Pb alloy is generally used for copper, nickel and cobalt applications. Ag/Pb alloy is the preferred alloy in zinc electrowinning Packing The finished anodes are packed together in wooden pallets with thick thermocol in between each Anode to prevent the individual anodes from bending.Do's & Dont;'s Remember, proper care of anodes will pay off in longer life. Try these suggestions with new Republic anodes. Do not leave new anode in chromium solution when tank is idle. Instead, remove them and place them in clean water after use until a uniform brown film of lead peroxide is formed on the surface. Do not confuse this dark brown lead peroxide coating with lead chromate. Lead chromate (PbCrO4) is yellow in color and acts as an insulation. This should be removed in order to restore the anode to the most efficient service level. We recommend that approximately two inches of lead anode be above the solution level at all times. We do not recommend mixing old and new anodes together. Adding new anodes intermittently in order to obtain amperage needed could result in new anodes scaling up very rapidly. If it is not practical to replace all anodes at one time, we suggest extreme care be given to the new anodes to assure proper breaking in for efficient performance.

Stainless Steel Brazing Welding Rods

Get Price Quote

We are a renowned Supplier of Stainless Steel Brazing Welding Rods based in Maharashtra, India. We procure the SS Brazing Welding Rods from known manufacturers who use high-grade metal and latest technology for fabricating them. To ensure customer satisfaction, we check the Welding Rods on stringent quality parameters before the final delivery. We are offering Stainless Steel Brazing Welding Rods to at reasonable rates. Specifications : Diameter - 2.5 mm, 3.2 mm, 4.0 mm, 5.0 mm Length - 300 mm, 350 mm, 400 mm Features : Wide melting range Low fluidity Reasonable in cost Durable and reliable

Aluminum Cube

Get Price Quote

SS Welding electrode

Get Price Quote

With a focus on the ever-evolving demands of our customers, we have come up with a wide range of uniquely designed SS Welding Electrode. Specifications: Welding Current: 90-120 Diameter: 2.0/2.5/3.2/4.0/5.0 mm Length: 300 mm-350 mm Operating Current: 100-200

Stainless steel tig filler rod

325 Per

100 Kilogram (MOQ)

Electro Rods

Get Price Quote

Electro rods we are instrumental in offering our clients a comprehensive range of electro rods which is appreciated for rigid construction, corrosion resistance, durable finish standards and high tensile strength. These are designed and developed in our state-of-the-art manufacturing unit from high grade raw materials that are acquired from reliable vendors. Our electro rods are extensively used in diverse industries like heavy engineering, paper, chemicals, cement etc and offered at industry leading costs.