Aluminium Ingots

205 Per Kilogram

Features Long lasting shine Impeccable finish Precise dimensions

Titanium GR. 5

Get Price Quote

We offer titanium gr. 5. Chemical composition weight% al v fe n c o h tot. ti min. 5,50 3,5 balance max 6,25 4,5 0,4 0,05 0,08 0,2 15 0,4 titanium gr 5 bar titanium gr 5 rod titanium gr.5 tube titanium gr.5 pipe titanium gr 5 plate titanium gr 5 wire titanium gr 5 fitting titanium gr 5 flange titanium grade 7 titanium gr 5 titanium gr 4.

Best Deals from Metal Ingot

White Metal Ingots

250 Per Kilogram

100 Kilogram (MOQ)

Cadmium Ingot

Get Price Quote

Pure Nickel Strips

2,600 - 5,500 Per Kilogram

Dear Sir, Greetings from RAMANI STEEL HOUSE ! Established since 1974, we are one of the largest stockholders of all Special GradeNickel Alloys, Super Alloys, Aerospace Alloys, Titanium Alloys, Stainless Steel, Duplex, Super Duplexas well as Pure Nickel for EV/BATTERY in India. We are thrilled to inform you that we have started manufacturing Nickel strips and H- type Nickel strips which are mainly used for assembly lithium-ion batteries. Our Product Range in this category : ü PURE NICKEL STRIP & COILS: · Pure Nickel Stripfor EV / BATTERY · H Type Strips / Custom Busbars For 18650 / 32650 / 21700 / 32700 cell 2P, 3P, 4P Strips Please find our Pure Nickel Strips inventory below with dimensions in which we have some ready stock: 0.10mm thick x 5mm / 8mm / 10mm / 150mm / 200mm width 0.15mm thick x 5mm / 8mm / 10mm / 12mm / 26mm / 27mm / 34mm / 45mm / 47mm / 64mm / 200mm / 230mm / 240mm / 245mm / 250mm / 260mm width 0.20mm thick x 6.3mm / 8mm / 10mm / 12mm / 15mm / 25mm / 27mm / 34.6mm / 200mm / 230mm / 240mm / 250mm / 260mm width 0.25mm thick x 200mm / 240mm 0.30mm thick x 8mm / 25mm / 27mm / 240mm width 0.50mm thick x 49mm / 63mm / 58mm / 73mm / 200mm / 240mm / 260mm width H Type Strips For 18650 / 21700 / 32650 / 32700 cell available in Stock. (Refer sample photos as attached) 21700 / 22650 / 26650 / 32700 cell 2P, 3P, 4P, 5P, 6P strips or custom Busbars can be developed as per your requirements or drawings in preferred thickness. Looking forward to your enquiries and a long term business relationship! Thank you.

Titanium

Get Price Quote

Grades :Grade 1, Grade 2, Grade 3, Grade 4, Grade 5, Grade 7, Grade 9, Grade 23Type:Seamless / Erw / Welded/ FabricatedRange :15 NB UP TO 600 NB IN SCH 5S, 10S, 10, 20, 40S, 40, STD, 60, 80S, 80, XS, 100, 120, 140, 160 etc.Form Round, square, rectangular, hydraulic etc.Length Single Random, Double Ranidom & Cut LengthEnd Plain End, Bevelled End, Treaded

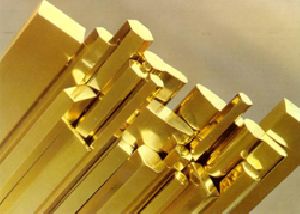

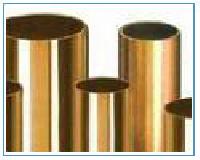

Non Ferrous Metal

Get Price Quote

We are offerig non ferrous metal, aluminium: aluminium, aluminium bronze, manganeese bronze. forms : round hexagonals, squares, rods, tubes, sheets, strips, foils, busbars, plate, flats, wire, tubings, sections & bushes. brass: free cutting brass, leading brass, foreign brass, reviting brass, lead free brass, neval brass. forms : round hexagonals, squares, rods, tubes, sheets, strips, foils, busbars, plate, flats, wire, tubings, sections & bushes. copper : electrolytic copper, electrolytic tough pitch copper, deoxidised copper, general purpose commercial copper. forms : round hexagonals, squares, rods, tubes, sheets, strips, foils, busbars, plate, flats, wire, tubings, sections & bushes. gunmetal, phospher, bronze 85555, 88102, 9010, ingots, hollow, bar, bushes & sheet, strips, wires etc. As per requirement.

Nickel Pellets

1,750 Per Kilogram

Cobalt

2,250 Per Kilogram

We are the main supplier of this product.

Tin

Get Price Quote

Tin ingots which we supply is LME Registered tin ingots. Tin is used in the manufacturing of super conducting magnets. Tin Ingots that are useful for application in electroplating, soldering and chemical formulation. While tin has many uses in alloys, it has few uses in it's pure elemental form. It is also used as a coating for steel cans. We are continuously striving to come out with sturdy and durable Tin Ingots.

Titanium

Get Price Quote

We are a quality conscious firm, thus never compromise on the quality of the offerings. In addition, we make use of quality tested raw material and modern work methods for manufacturing the same. Product packaging is done using industrial grade materials by us to ensure safe and undamaged delivery of consignments. Further, we provide tailored packaging solutions.

industrial non ferrous metal

Get Price Quote

We are the distributors of a range of non ferrous metal that can withstand the higher & critical application and hence are best suited for the boilers, power house, oil, gas & petroleum industries. Our products also conform to ASTM A 335 P-11, P-22, P-5, P – 9, etc. ASTM A 213 T – 11, T – 22 etc., with IBR certificate.

Industrial Non Ferrous Metal

Get Price Quote

silicon metal lump, Cobalt Metal Powder, Magnesium Metal Ingot

Non Ferrous Metal

Get Price Quote

We are Importers, Exporters, Stockist & Suppliers of Copper, Brass, Aluminium, Bronze, Gunmetal, Zinc, Lead etc. in form of Bar, Wire, PVC Coated Copper Coil, Coils, Round, Sheets, Plates, Channel, Angle, Pipes etc.

Non Ferrous Metals - 02

Get Price Quote

For every need of all kinds of non ferrous metals feel free to avail our matchless services. We make available the exception quality industrial non ferrous metals such as aluminum, brass, copper, gunmetal, phosphor, bronze and so on and so forth. They are accessible in various forms like round hexagonal, squares, rods, tubes, sheets, strips, foils, bus bars and many more. These non ferrous metals are extensively used for array of purposes in various industries and manufacturing units. And when it comes to wholesale non ferrous metal suppliers in the market, we are reckoned as the best. Besides, we are counted among the best non ferrous metal suppliers from India. Aluminium : Aluminium, Aluminium Bronze, Manganeese Bronze. Forms : Round Hexagonals, Squares, Rods, Tubes, Sheets, Strips, Foils, Busbars, Plate, Flats, Wire, Tubings, Sections & Bushes. Brass : Free Cutting Brass, Leading Brass, Foreign Brass, Reviting Brass, Lead Free Brass, Neval Brass. Forms : Round Hexagonals, Squares, Rods, Tubes, Sheets, Strips, Foils, Busbars, Plate, Flats, Wire, Tubings, Sections & Bushes. Copper : Electrolytic Copper, Electrolytic Tough Pitch Copper, Deoxidised Copper, General Purpose Commercial Copper. Forms : Round Hexagonals, Squares, Rods, Tubes, Sheets, Strips, Foils, Busbars, Plate, Flats, Wire, Tubings, Sections & Bushes. Gunmetal, Phospher, Bronze 85/5/5/5, 88/10/2, 90/10, Ingots, hollow, Bar, Bushes & Sheet, Strips, Wires etc. as per requirement.

ferrous and non-ferrous metals

Get Price Quote

STAINLESS STEEL, BRASS, COPPER, ALUMINIUM, INCONEL, NICKEL etc. & EN-STEEL SHAFTS etc.We have carved for ourselves a unique niche in the industry by offering a world class collection of Ferrous And Non Ferrous Metals. Appreciated for their reliability, sturdiness and fine finish, these offered metals are well renowned in the industry. Together with this, their fine functionality, corrosion resistance and ruggedness make these highly demanded.Features: Excellent Quality Multiple & Fix Length Various Dimension & size

Ferrous and Non-ferrous Metals

Get Price Quote

silicon metal lump, Manganese Metal Flakes, Molybdenum Metal Rods

Aluminium Alloy Ingots

132 Per Kilogram

Non Ferrous Metals

Get Price Quote

Our company is amidst reputed Non Ferrous Metals Stockists and Suppliers in Mumbai. The wide range of Non Ferrous Metals which we are offering possesses unmatched quality, robust structure, dimensional accuracy, abrasion resistance, and various other features. These Non Ferrous Metals have been procured from leading companies of the country. We provide our extensive assortment of Non Ferrous Metals in different specifications to cater to the requirement of diverse clientele. One van avail these Non Ferrous Metals from us at market leading price. Non Ferrous Metals Are Used In Marine and shippingSugar millsDistilleriesInduction furnacesPlumbingAir-conditioningSolar systems We Deal in Below Mentioned Products MonelInconnelAlloy steelDie steelTool steelIncoloyCarbon steelMild steel

Titanium Grades Manhar Metal

Get Price Quote

Titanium Grades:-Manhar Metal Supply Corporation Supplies Titanium In Different Grades. We Have Titanium Grade 1, Grade 2, Grade 5, Grade 7, Grade 9, And Grade 12. Titanium And Its Alloys Have Proven To Be Technically Superior And Cost-Effective Materials Of Construction For A Wide Variety Of Aerospace, Industrial,Surgical Implants, Gold Refinery , Anodising Plants , Heater For Industrial Use , Marine And Commercial Applications. In North America,Approximately 70% Of The Titanium Consumed Is Utilized For Aerospace Applications.Due To The Expansion Of Existing Applications And The Development Of New Uses, The Greatest Growth Will Occur In The Industrial, Marine And Commercial Sectors Titanium is as strong as steel but much less density. It is therefore important as an alloying agent with many metals including aluminium, molybdenum and iron. These alloys are mainly used in aircraft, spacecraft and missiles because of their low density and ability to withstand extremes of temperature. They are also used in golf clubs, laptops, bicycles and crutches. Power plant condensers use titanium pipes because of their resistance to corrosion. Because titanium has excellent resistance to corrosion in seawater, it is used in desalination plants and to protect the hulls of ships, submarines and other structures exposed to seawater. Titanium metal connects well with bone, so it has found surgical applications such as in joint replacements (especially hip joints) and tooth implants. The largest use of titanium is in the form of titanium(IV) oxide. It is extensively used as a pigment in house paint, artists’ paint, plastics, enamels and paper. It is a bright white pigment with excellent covering power. It is also a good reflector of infrared radiation and so is used in solar observatories where heat causes poor visibility. Titanium (IV) oxide is used in sunscreens because it prevents UV light from reaching the skin. Nanoparticles of titanium (IV) oxide appear invisible when applied to the skin. The Properties And Characteristics Of Titanium Which Are Important To Design Engineers In A Broad Spectrum Of Industries Are: Excellent Corrosion Resistance: Titanium Is Immune To Corrosive Attack By Salt Water Or Marine Atmosphere. It Also Exhibits Exceptional Resistance To A Broad Range Of Acids , Alkalis, Natural Waters And Industrial Chemicals. Superior Erosion Resistance: Titanium Offers Superior Resistance To Corrosion, Cavitation Or Impingemnet Aatack. Titanium Is Atleast 20 Times More Erosion Resistance Than Copper Nickel Alloys High Heat Transfer Efficiency: Under”In Service” Conditions, The Heat Transfer Properties Of Titanium Approximate Those Of Admirately Brass And Copper Nickel.There Are Several Reasons For This: 1) Titanium’s Higher Strength Permits The Use For Thinner Walled Equipment. 2) There Appears To Be Unusual And Benefical Characteristics In Titanium’s Inherent Oxide Film. 3) The Relative Absence Of Corrosion In Media Where Titanium Is Generally Used Leaves The Surface Bright And Smooth For Improved Lamellar Flow. 4) Titanuim’s Excellent Erosion-Corrosion Resistance Permits Significantly Higher Operating Velocities. Superior Strength to weight Ratios The Densities Of Titanium-Based Alloys Range Between 160 Lb/In3(4.43gm/Cm3) And 175lb/In3(4.85 Gm/Cm3).Yield Strengths Range From 25,000 Psi(172 Mpa )Commercially Pure(Cp) Grade 1 To Above 200,000 Psi (1380 Mpa) For Heat Threated Beta Alloys.The Combination Of High Strength And Low Density Results In Exceptionally Favorable Strength-To-Weigth Ratios For Titanium Based Alloys.These Ratios For Titanium Based Alloys Are Superior To Almost All Other Metals And Become Important In Such Diverse Applications As Deepwell Tube Strings In The Petroleum Industry And Surgical Implants In The Medical Field. Special Information For Fraction of Titanium Keeps tools Sharp Titanium Has A Tendency To Gall, And Its Chips Can Weld To The Cutting Edged Of The Tool. This Is Particularly So Once Tool Wear Begins.Sharp Tools Should E Employed At All Times And Should Be Replaced Before They Dull. The Feed Should Not Be Stopped While The Tool And Work Piece Are In Moving Contact. Grinding Of Titanium In Grinding,The Difference Between Titanium And Other Metals Is The Activity Of Titanium At High Temperatures.At The Localized Points Of Wheel Contact Titanium Can React Chemically With The Wheel Material.The Most Important Facts To Consider In Order To Prevent This And Ensure Successful Grinding. Joining Of Titanium Titanium And Titanium Alloys Can Be Readily Joined By Normal Mechanical Fastener Techniques.With The Exception Of Brazing And Friction Welding,These Methods Are The Only Satisfactory Means Of Making Joints Between Two Nonweldable Titanium Alloys Or Between Titanium And Dissimilar Materials. Hints For making Titanium Titanium Can Be Fabricated Using Techniques Which Are No More Difficult Than Those Used To Machine Type 316 Stainless Steel.Commercially Pure Grades Of Titanium With Tensile Strengths Of 35,000 To 80,000 Psi Machine Fabricate For Easier Than The Aircraft I.E. 6al-4v With Tensile Strenghts Up To 200,000 Psi. Welding Titanium In General,Welding Of Titanium And Its Alloys Can Be Readily Performed, But It Is Necessary To Exclusive Reactive Gases,Including Oxygen And Nitrogen From The Air,And To Maintain Cleanliness.Thus Weld Properties Are Heavily Influenced By Welding Procedured, Especially By The Adequacy Of Insert Gas Shielding. Fire Prevension Storage Of Coarse Titanium Turnings And Chips Is Relatively Safe. Storage Or Accumulation Of Titanium Fines Constitues A Fire Hazard.Clean Machines And Good Workshop Practice Are Usually Sufficient To Avoid Any Danger Of Fire When Machining Titanium. Application Titanium Is Used In Steel As An Alloying Element (Ferro) To Reduce Grain Size And As A Deoxidizer, And In Stainless Steel To Reduce Carbon Content. Titanium Is Often Alloyed With Aluminium (To Refine Grain Size), Vanadium, Copper (To Harden), Iron, Manganese, Molybdenum, And With Other Metals. Applications For Titanium Mill Products (Sheet, Plate, Bar, Wire, Forgings, Castings) Can Be Found In Industrial, Aerospace, Recreational, And Emerging Markets. Powdered Titanium Is Used In Pyrotechnics As A Source Of Bright-Burning Particles. Industrial Welded Titanium Pipe And Process Equipment (Heat Exchangers, Tanks, Process Vessels, Valves) Are Used In The Chemical And Petrochemical Industries Primarily For Corrosion Resistance. Specific Alloys Are Used In Down Hole And Nickel Hydrometallurgy Applications Due To Their High Strength (E. G.: Titanium Beta C Alloy), Corrosion Resistance, Or Combination Of Both. The Pulp And Paper Industry Uses Titanium In Process Equipment Exposed To Corrosive Media Such As Sodium Hypochlorite Or Wet Chlorine Gas .Other Applications Include: Ultrasonic Welding Wave , Wave Soldering, And Sputtering Targets. Titanium tetrachloride a colorless liquid, is important as an intermediate in the process of making and is also used to produce the Ziegler-Natta catalyst.