Stainless Steel PET Blow Mould

45,000 Per Piece

1 Piece (MOQ)

Stainless Steel Thin Wall Container Mould

250,000 - 650,000 Per piece

1 Piece (MOQ)

Best Deals from Metal Mold

Copper Mould Tube

Get Price Quote

10 Piece (MOQ)

Metal Injection Molding

Get Price Quote

We are offering metal injection molding—mim—offers a manufacturing capability for producing complex shapes in large quantities. The process utilizes fine metal powders (typically less than 20 micrometers) which are custom formulated with a binder (various thermoplastics, waxes, and other materials) into a feedstock which is granulated and then fed into a cavity (or multiple cavities) of a conventional injection molding machine. After the “green” component is removed, most of the binder is extracted by thermal or solvent processing and the rest is removed as the component is sintered (solid-state diffused) in a controlled-atmosphere furnace. The mim process is very similar to plastic injection molding and high-pressure die casting, and it can produce much the same shapes and configuration features. However, it is limited to relatively small, highly complex parts that otherwise would require extensive finish machining or assembly operations if made by any other metal-forming process. Advantages: the advantages of the metal injection molding process lie in its capability to produce mechanical properties nearly equivalent to wrought materials, while being a net-shape process technology with good dimensional tolerance control. Metal injection molded parts offer a nearly unlimited shape and geometric-feature capability, with high production rates possible through the use of multi-cavity tooling. Materials range the metal injection molding industry can manufacture an extremely wide variety of metal alloy compositions for use in your application. The alloy families shown below make up a broad representation of the spectrum of alloys which can behave been produced for various applications. If you do not see the exact alloy or alloy family shown on our extensive list in which you have interest, please contact your supplier in order to see if the alloy or a substitute alloy is available. Working closely with your supplier will enable you to find the best solution for your application. The most common alloy families are: iron, low-alloy steels, stainless steels other alloys: aluminum alloys, bio-compatible alloys, carbides, ceramics, cobalt-based alloys, controlled-expansion alloys, copper and copper alloys, hardmetals, heavy-metal alloys, magnetic alloys (soft and hard), nickel-based alloys, precious metals, reactive metals, shape-memory alloys, specialty alloys, titanium and titanium alloys, tool steels.

vacuum forming moulds

Get Price Quote

Vacuum forming moulds which ensures high quality range of products. With our creative team of designers and craftsmen we are able to serve our customers by providing them customization as per their requirement.

ingot mold

15,000 - 45,000 Per Piece

5 Piece(s) (MOQ)

Stainless Steel Flan Mold

Get Price Quote

chalk moulds

Get Price Quote

We specialize in manufacturing, exporting and supplying a qualitative range of Chalk Making Moulds. Designed and developed with utmost care, these devices are available in all standard and technical specifications. Our products are available in various dimensions, sizes and technical specifications as per the exact requirements of clients. Besides, our experienced quality controller’s quality check these devices on various parameters before delivery to offer flawless range at our clients’ end. Gun Metal Chalk Mould with Copper Pins on fibre glass plates for ejection of chalk sticks.

Graphite Mould For Gold Ingots

900 - 2,000 Per No

1 no (MOQ)

We have skilled professionals at our firm for offering best Graphite Mould for Ingots. These presented products are superior in quality and available in the market in various sizes and shapes. Moreover to this, these presented products are best in finishing and easier to use. Features: Perfect finish Different sizes Reliable

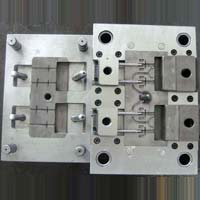

Zinc Die Casting Molds

Get Price Quote

Our Zinc Die Casting Molds are known for their high dimensional accuracy and long functional life. We are renowned Manufacturers, Suppliers and Exporters of Zinc Die Casting Molds from Maharashtra. Our Zinc Die Casting Molds have sturdy construction and are coated with an abrasion resistant material. Owing to our reliable logistics network, we are capable of delivering bulk orders of the Die Casting Molds within stipulated time.

metal molds

Get Price Quote

Metal mold or metal casting is related to metal moulds or permanent molds made from metal. Typical parts include gears, Wheels, Pipe fittings and engine pistons. A mould is formed that of a desired shape and molten metal is then poured into it to get it into a desired shape. Metal molds can be made from various metals but generally they are made from Aluminum, Iron, or Brass. Moulds are of two types • Open Mould • Closed Moulds • Plastic Molds Thermoplastic processing involves moving the viscous material into thermoplastic characteristics of some form or mold and then cooling it. Off course these products are light in weight compared to metal products and so more popular. Plastic molds are made from many compounds It is very easy to make it. A foam piece is transformed into a box size. This box is filled with mold. After it is dry it is removed. • Rubber Molds Rubber molding is done by passing the material into a particular shape at high temperature and pressure. Rubber molds are durable. They can be used to make number of copies with other materials. They are used to make candle molds, soap molds etc. • Thermo Cole Molds We offer our clients number of Thermocole packaging molding material meeting successfully the requirements of our customer.

Mild Steel Blow Mould

35,000 Per Piece

Mild Steel Injection Mould

27,500 Per Piece

Moulds for Lids

Get Price Quote

If you cater to any kind of food or beverage packaging industry, or a FMCG packaging industry, you will need special grade lids for the containers. Mouldcraft designs special moulds for manufacturing lids for all types and shapes of plastic food containers. Over the years, we have become the mould manufacturer of choice and delivered hundreds of moulds for lids across a variety of thermoforming machines. While selecting a mould manufacturer for your plastic lid production, you decision should be govern by several factors in terms of utility and quality. More qualities are: Quality of material to be used Applications such as leak-proof seal, food-grade material, microwave-safe, etc. Durability and pressure specifications If you are a manufacturer of plastic Glasses, Cups, Conatiners, bowls, Mouldcraft offers you thermoforming Lid moulds, manufactured and designed as per your requirements. The various kinds of Lid moulds manufactured by us are: Thermoforming Lid moulds for Glasses Thermoforming Lid moulds for Cups Thermoforming Lid Moulds for Containers Thermoforming Lid moulds for Bowls Lids find a variety of usages across industries and applications like Hospitality - parties, functions, outdoor events, Regular use - offices, canteens and mess, Restaurants, Ice cream joints, Theatres and malls, Cafeterias, Catering services, Drive-in services, Packaging of fast food, salads, Gifts and confectionaries, Eateries, Cola Glasses, Milkshake glasses, Juice Glasses, Take-away glasses, Coffee Glasses, Tea Glasses, Dairy products, Ice cream, etc. Mouldcraft also manufactures custom designed moulds for lids required for applications that use specialized materials and adhere to specific performance standards. We can manufacture moulds for producing containers in varying sizes and designs for highly durable, attractive, and user-friendly containers for foodstuffs, Punnets for fresh fruits and vegetables, Hingable boxes for Sandwiches, etc. Contact Us for Specification sheets and other characteristics of thermoforming moulds for lids. Share your requirements and we will be happy to assist you.

Stainless Steel Tear Drop Molds

Get Price Quote

1000 Piece (MOQ)

Metal Leg Chair Mold

Get Price Quote

Onemold is professional metal leg mould maker and exporter. Every year we have manufactured number of metal leg chair moulds. Use of latest technology, professional designers to develop designs in latest 3d softwares, in depth understanding of the requirement from our customers keep us ahead in the list of metal leg chair mold makers. We have experience in developing many molds for metal leg chairs which are used with metal legs. For inquiries please contact us. • product size: on request • product weight: 1000 gms. • suitable machine: 800 ton. • mould steel: p20 core and cavity. • mould ejection: automatic.

Mild Steel Plastic Trash Bin Mold

200,000 Per Piece

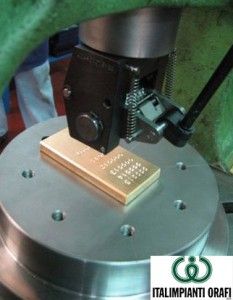

Mold for ingots and numbering equipment

Get Price Quote

Molds and for ingots numbering equipment: • Numerazone with mold and manual rocker • Several models of rockers

plastic cup thermoforming mould

Get Price Quote

Aluminium Cake Mould

310 Per Piece