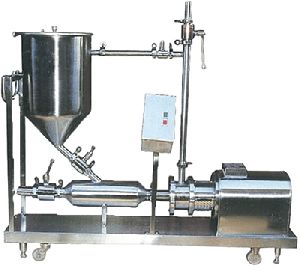

Volumetric Liquid Filling Machine

Liquid filling machine is designed to continuously fill various liquids such as syrups, oils, liquid soaps, beverages etc. It is very compact and occupies very little space. Our client can also avail a vast range of Volumetric Liquid Filling Machine widely used for filling various free-flowing granular products like tea, sugar, salt, pulses, and grains. The combination of high-end technologies and quality raw material has contributed in the durable, safe, easy and reliable operation of these fillers. These Semi Automatic Volumetric Liquid Filling Machines are manufactured from high grade quality material and are easily available at very reasonable price in market. These machines are suitable for round or flat shape bottles or vials. Our machines have output of maximum 20 Products per minute depending on nature of liquids, neck diameter or vial/bottle and fill volume. The range is available in different models and specifications. Along with standard range , we offer customized versions to suit specific requirements. High technology ensures easy operations and installation. Maintenance free, user friendly operations and high efficiency are some of the features because of which these are highly demanded in national as well as international markets.

...more

Rotary Bottle Washing Machine

Bottle washing machine is with high performance, rust resistance, excellent functionality we provide customized options for washing series. Washing of bottles take place with five various washing type with 10 nozzles for optimum washing, our technicians take quality material for proper wash of bottle, all machine parts and jets are made from SS 316 tools. It is manufactured with rough stainless steel, which is highly used in several ceramic, chemical, food products industries. SALIENT FEATURES : • The structure is made of SS 304. • The contact parts such as washing nozzle, washing pump impeller, tanks, cup/bottle holder plate are made of Stainless Steel 304. • The tanks capacity is 75 litres each. • Pumps and tanks are mounted on portable stand for easy maintenance and cleaning purpose. • Stationary nozzles to eliminate contamination of water cycles. • Four inner wash (Included one air wash , two inner wash with recycled tray) & one outer wash •Individual solenoid valve use for each wash - which eliminates carbon plate and other accessories. This is to avoid leakages and minimize the maintenance ratio. • Bottle guide system especially for lightweight bottle. • SS glycerin fill pressure meter.

...more

Rapid Mixer Granulator

MEVISH’s Rapid Mixer Granulators operates at a low cost coupled with high productivity and is designed in a manner to achieve perfect mixing & consistent granules. MEVISHs Rapid Mixer Granulators Excellent mixing & close control over the size of granules leads to faster speed in tableting along with superior quality and minimal rejections. MEVISH’s Rapid Mixer Granulators meets special needs of tablet manufacturing technology by reducing processing time, homogenous mixing, uniformity of size and above all maintaining improved hygiene compliant to GMP norm MEVISH’s Rapid Mixer Granulator Machine consists of various parts ie. Mixing Bowl, Mixing Blades, Granulator, Pneumatic Discharge, Motor, Gear Box, Operating Panel and the Control Panel. SALIENT FEATURES : • Capacity 25 Ltrs to 1000 Ltrs • Dual Speed Impeller And Chopper • Suitable For Efficient & Fast Mixing Of Granulation Of Ingredients • Material Handling System Is Provided For Loading Of Material • CIP System Will Be Provided With Pump As Optional • M.O.C. S.S. 304/316/316L •Consistant Quality In Each Batch • Fully Hygienic Mixing. • Option - Arrangement For Binding Spray. • Machine With PLC System As An Optional • CGMP Model With Documentation (IQ, DQ, PQ, OQ) - As Option

...more

Planetary Mixer

Planetary Mixers offered by us are used for allowing flawless mixing of ointments, wet mass, paste, cream as well as dry powders. This rotation mixer makes use of gear transmission for driving two impellers rotating in same directions, thus producing interactive kneading, twisting as well as dispersing effects. Further, both impellers revolve around mixing tank and assist in bringing materials inside for complete mixing. Presently, we specialize in manufacturing planetary mixers for: Pharmaceutical industry Food industry Fine chemical industry SALIENT FEATURES : • 50 KG to 300 KG • Plate are made of MOC Stainless Steel 304 • Anchor type Blade

...more

packing conveyors

With our years of experience & in-depth knowledge in this field, we are engaged in offering a quality-assured array of Packing Conveyor Belts. SALIENT FEATURES : • Model : 8', 12', 16'. & 20' • The structure is made of MOC SS 304. • TAvailable as per your required Speed, Length, Hight & width • Conveyor Belt is supplied with AC frequency drive • Special self-alignment bearing ensures smooth rotation of the roller • Imported PVC endless Belt

...more

Ointment Manufacturing Plant

We are amongst the reputed manufacturers and exporters of Ointment Manufacturers Plant in India. Designed to perfection, the plant is extensively used for manufacturing pharmaceutical ointments, cream, sterile preparations, cosmetic, suspensions and gels. For optimum performance, the plant is provided with water phase vessels, main manufacturing vessel and pre-mixing wax. For emulsifying, the main vessel is provided with bottom high-speed homogenizer and slow speed anchor agitator for mixing. Creams & Ointments:- Ointment Manufacturers Plant in India. Designed to perfection, the plant is extensively used for manufacturing pharmaceutical ointments, cream, sterile preparations, cosmetic, suspensions and gels. SALIENT FEATURES : • The structure is made of MOC SS 304 • 50 KG TO 2000 KG • Hydraulic lid lifting for MFG. Vessel • Dual anchor agitator with fix anchor • Bottom / Top fully Homogenizer • PLC based fully automatic plant also available •CGMP with documentation

...more

Octagonal Blender

The Octagonal Blender is an efficient and versatile blending machine for mixing and lubrication process of dry granules homogeneously. Two third of the volume of the Cone Blender is filled to ensure proper mixing. The Octagonal Blender gives the best result for granules due to very slow speed and octagon shape of the container. It can be used for Pharmaceutical, Food, Chemical and Cosmetic products etc. In Octagonal Blender, the granules come from all sides due to the octagonal shape of the product container, hence requirement of RPM is less. Suitable mainly for Crystalline & Granular type material. This type of material gets sufficient continuous movement due to their shape if container have only slow movement and will result in good quality of blending/lubrication of granules Salient Features: Suitable for dry mixing of products in granule form. Easy for loading and unloading of material. Easy for cleaning. All contact parts are made out of SS 304 / SS 316 or SS 316 L quality material, as per customer requirement. The octagonal shape & slow speed of rotating gives sufficient continuous movement to the granules, result in good quality. Simple design requires minimum maintenance. SALIENT FEATURES : • Suitable For Quick And Efficient Mixing For A Complete Range Of Powders, Particulate And Granular Materials. • Homogeneous Mix. Gentle Tumbling Action With A Specially Designed Baffle. • Easy Charging Of Materials Through S.S. Bins. • Capacity - 20 Ltrs. to 4000 Ltrs • MOC - S.S. 304/ 316/ 316 L • Shape Of Container - Polygon Shaped Frustum. • S.S. Octagon Type Body With Rectangular Central Portion Top And Circular Bottom With A Butterfly Valve. • CGMP Model With Documentation (IQ, DQ, PQ, OQ) - As Option

...more

Multi Mill

MULTI MILL is designed to utilise the principle of variable force swing beaters having both knife and impact edges rotating within a selected screen to control the particle reduction. Material fed in to the processing chamber moves to the periphery and passes through the screen radially and tangentially. Finally the processed material gets collected in to the container kept below the processing chamber. SALIENT FEATURES : • Suitable for Dry Granulation / Pulversing / Shredding & Chopping of Materials. • Multi Speed Drive for Various Product Grading. • Easy Dismantling & Cleaning. • Output 20kg To 400kg / HR Depend upon Machine Model, Characteristic of Product & the Screen Size. • Easy Maneuverability with the help of Castor Wheels. • Beaters 8 to 12 nos. with Knife / Impact Edge & 2 Scrapper Blades. •Rotor Speed - 750 / 1500 / 2100 / 3000 RPM Approx.

...more

Lobe Pump

Lobe Pumps that are designed specifically for cosmetics, pharmaceutical and food industry. BPI Lobe pumps are suitable for pumping Chocolate, Cocoa Butter, Soap, Fruit Pulp, Face Cream, Butter, Minced Meat, Edible Oil, Fruit Juices, Ointments, Malt, Toothpaste, Ghee, Ketchup, Glucose, Jelly, Lotions, Fatty Acids, Shampoo, Dyes & Starch, Starch, Dairy Products, Ice Creams, Sugar Confectionery, Sugar Syrup, Liquid Glucose, etc. in their respective industries. Our lobe pumps are manufactured with hardened and ground timing gears for delivering high performance without metallic inclusions. Our Lobe pumps provide smooth and noiseless operation due to precision Timing Gears and highly polished Lobes. SALIENT FEATURES : • SS Easy clean positive displacement Rotary Lobe Pumps • Full range of Mew Lobe Pumps perfoemance date

...more

Liquid Syrup Manufacturing Plant

The Liquid Manufacturing Plants are ideal tools for the pharmaceutical industry for the production of Oral Liquids. It is specially designed to take care of two critical factors which directly affect the quality of the Liquids. Minimum manual handling of Liquid. SALIENT FEATURES : • Model : 1000 liters to 10,000 liters • Electric heating also possibles for smaller capacity • Top mounting stirrer also available • PLC based fully autometic plant also available • Better surface finish • Easy portability •MOC SS 316/316L/304 • CGMP with documetion

...more

Inline Homogenizer

Bottle washing machine is with high performance, rust resistance, excellent functionality we provide customized options for washing series. Washing of bottles take place with five various washing type with 10 nozzles for optimum washing, our technicians take quality material for proper wash of bottle, all machine parts and jets are made from SS 316 tools. It is manufactured with rough stainless steel, which is highly used in several ceramic, chemical, food products industries. SALIENT FEATURES : • The structure is made of SS 304. • The contact parts such as washing nozzle, washing pump impeller, tanks, cup/bottle holder plate are made of Stainless Steel 304. • The tanks capacity is 75 litres each. • Pumps and tanks are mounted on portable stand for easy maintenance and cleaning purpose. • Stationary nozzles to eliminate contamination of water cycles. • Four inner wash (Included one air wash , two inner wash with recycled tray) & one outer wash •Individual solenoid valve use for each wash - which eliminates carbon plate and other accessories. This is to avoid leakages and minimize the maintenance ratio. • Bottle guide system especially for lightweight bottle. • SS glycerin fill pressure meter.

...more

Fluid Bed Dryer

Mevish’s Fluid bed dryer is a process unit for preparation of granulated materials for solid dosage forms in batch and continuous batch operations. The system is applied for drying, agglomerations and top spraying upon fluidized bed. Fluid Bed Dryer manufacturers, suppliers and exporters in various capacities & batch sizes. Batch size means the weight of wet product i.e. including moisture / solvent that can be charged in the dryer at a time. In case of very granular or crystalline material the capacity may be increased by about 15 to 20%. Mevish provides several options that can be supplied with Fluid Bed Dryer if opted such as Inflatable tubes, PLC automation control, AC Variator for blower, WIP CIP system, pneumatic damper on ducts, police filter, Scrubber on discharge, steam fittings if steam heater, electrical heater, chilling coil, solid flow monitors, Top spray arrangement with holding tank and peristaltic pump, EX rated FLP construction etc. SALIENT FEATURES : • Very Versatile Process Equipment For Uniform And Efficient Drying Of Products. • Fully Automatic Operation Based on PLC Control / Without PLC Control • Minimum Handling And More Hygienic • Lifting & Tilting Device Of Product Container For Easy Handling • Capacity Available From 5 Kgs to 500 Kgs. • FLP Models Available As Option • MOC S.S. 304/ 316/ 316L • Option - Steam Heated Or Electric Heated Blower • CGMP Model With Documentation (IQ, DQ, PQ, OQ) - As Option.

...more

Filter Press

Filters Pressused for filtering process in pharmaceuticals, coconut processing plants, milk dairies, distilleries, breweries etc. We supply a wide range of Filters and transfer pumps according to desired capacity that are made using high quality stainless steel. CGMP Zero Hold-Up / Sparkler Type Filter Press consist of Stainless Steel Shell & Top cover using bolts to give pressure tight enclosure. The filter cartridge assembly inside the shell consists of several horizontally arranged disc type filter plates with perforated supporting screens, filter media & interlocking cups. The entire assembly complete with pump & piping connection is mounted on a suitable S.S. Trolley. SALIENT FEATURES : • Available model 8", 14" , 18", 24" & 33". •Total access for fast cartridge removal and cleaning filter press machine • Centrifugal / Gear / Lobe pumps can be offered, which can also be used for liquid transfer • MOC SS 304/316/316L. • Complete filtration of the batch without any hold up due to reverse flow of liquid, making it cost efficient and time saving • In compliance with CGMP •Pressure gauge, safety valve & air vent provided to ensure safe operation

...more

Colloid Mill

MEVISH Colloid Mill is suitable for Homogenising, Emulsifying, Dispersing, Mixing, Comminuting of liquids to highly viscous products. It is based on rotor- stator principle. It is available in plain as well as Water Jacketed model which is suitable for heat sensitive products. Flame proof electrical can be supplied on demand at extra cost. . Colloid Mill is based on Rotor and stator principle, as you decrease the gap between Rotor and Stator you can get fine product.Colloid Mill Machine is a machine used in the disintegration of solid particles or droplet size of a liquid present in suspension or emulsion. The Colloid Mill Machine consists an inlet (which is subjected to a tremendous shearing action that effects a time dispersion of uniform size) and an outlet. Colloid mill works on the rotor-stator principle.

...more

Food Processing Machines

Be first to Rate

Rate ThisOpening Hours