Wave Spring Seals

Single Wave spring seals are designed for bi-directional and work with high viscous, abrasive media ,water, oils, fuels, low aggressive chemical substances and liquids containing solid particles. The spare parts are interchangeable without modification. seal faces are easily inserted.

Size : 15 mm to 100 mm

...more

Water Pump Seals

Rubber Bellow Seals are mainly use in waste water treatment plants for the sewage applications.Due to its compact design it can be easily mounted. It has a unique rubber bellow secondary seal, which provides a high degree of axial flexibiiity and protects the shaft/ sleeve from fretting. Rubber Bellow Mechanical Seals can be use regardless of direction of rotation since the driving torque is not transmitted through the coil spring. The required driving torque is through the spring and spring holder.The single coil spring will avoid effluent particle. Application Sewage applications.Waste water pumps.Fuel injection pumps.Hot & cold-water pumps.

Speed : 20 m/s

Size : 2850 rpm (Max)

...more

Waste water Pump Seals

Supported by our experience of the industry, we have been able to manufacture, supply, trade and export a qualitative range of Water Pump Mechanical Seal used in various industries. Water Pump Seals is a compact, single-spring, elastomer bellows mechanical seals. Water Pump seals are designed for use in small centrifugal water pumps, deep and shallow-well jet pumps, swimming pool pumps, submersible pumps and waste water pumps. Application Sewage Water.Light Chemical.centrifugal water pumps.submersible pumps.waste water pumps.

...more

VMC Precision Machined Components

We are widely acknowledged for providing an exquisite range of VMC Precision Machined Components. Appreciated for their high tensile strength and high efficiency, these VMC Precision Machined Components are highly in demand. These VMC Precision Machined Components are capable enough to enhance the efficiency of the wind mill. Our VMC Precision Machined Components are available in different types, namely VMC components, VMC machined components, machining work, precision brass turned components, precision components, precision job work, precision machining jobs, turning job work, turning work, brass turned components, precision machined components and assemblies, industrial components, precision stainless steel components, precision aluminum machined components and special category parts.

...more

Unbalanced Mechanical Seals

Multi Spring Unbalance Seals is pusher type unbalanced seals used to avoid distortion at high speeds and ensure uniform pressure on seal faces under all operating conditions and Prevents any kind of leakage. Multi Spring unbalanced seals can be easily assemble or dismantled through circlip provided and can be change to balance version by changing only the seal ring and the secondary seal. Multi Spring unbalanced Mechanical sealsare compact in design suiting all types of rotating equipments, pumps, mixers,agitators and compressors. Application Generally used in Petrochemicals, Light Hydrocarbons & General Industrial fluids. Material And Operating Limits

Size (Inches) : 10 mm to 150 mm

...more

tungsten carbide seal faces

Tungsten carbide Seal Faces is very versatile seal face like Silicon Carbide.it is widely used seal faces material with high wear resistance, high fractural strength, high thermal conductivity, and small heat expansion co-efficient. Tungsten carbide is the best material to resist heat and fracture in all hard face materials.

...more

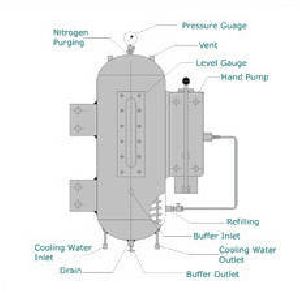

Thermosyphone Pot

Thermosyphon vessel is basicaly used as a storage & pressurising unit. This is used for Double Mechanical seals in back to back or tandem seal arrangement to provide necessary lubrication and cooling to the seal faces to achive recommended seal life. This is equipped with cooling coil inside the shell to bring down the temperature of barrier fluid coming from seal to Thermosyphon Pot. it is also provided with Hand Refill unit that assists in maintaining buffer fluid level during involved operations without bringing any noticeable disturbance in the involved ongoing process.

...more

Thermosyphon Vessel

Thermosyphon Vessel is basically used as a storage & pressurizing unit. Thermosyphon Vessel is ideal for double mechanical seals in back to back or tandem seal arrangement to provide necessary lubrication and cooling to the seal faces so as to achieve recommended seal life. Thermosyphon Vessel is equipped with cooling coil inside the shell to bring down the temperature of barrier fluid coming from seal to thermosyphon pot. It is also provided with hand refill unit that assists in maintaining buffer fluid level during involved operations without bringing any noticeable disturbance in the involved ongoing process.

...more

Textile Plant Mechanical Seals

Textile Seals are widely used in Textile plants. The "Micro Seals" Designed various types of Textile Mechanical seals for used in yarn & fibre dyeing plants,cloth dyeing application plants &high speed jet dyeing plants. The Textile Seals are non-clogging and self cleaning which make them suitable for use in various applications. Our Textile seals Generally used for Diaphragm Elastomer to Normal pressure machine like a mercerizing machine & pretreatment machine (Benninger -Make) Application Caustic.Acidic.Sodium Hydrogen Carbonate.

Pressure : Normal

Temperature : Normal

Size (Inches) : As Per Machine Requirement

...more

Textile Mechanical Seal

Textile Mechanical Seal are widely used in textile plants. We offer various types of Textile Mechanical Seals for use in yarn & fiber dyeing plants, cloth dyeing application, and high speed jet dyeing plants. These Textile Mechanical Seal are non-clogging and self cleaning which make them suitable for use in various applications. Our Textile Mechanical Seals are generally used for diaphragm elastomer to normal pressure machine like a mercerizing machine & pretreatment machine (benninger -make). Application : Caustic Acidic Sodium Hydrogen Carbonate Operating Limits : Pressure : Normal Temperature : Normal Sizes : As per Machine Requirement Material : Seal Face : Carbon, Siliocn, Ceramic, Tc Secondary Seals : Viton Ptfe Gft Metal Parts : SS 316, Alloy 20, Hastelloy C

...more

Teflon Gaskets

Micro seals is a recognized manufacturer of high quality PTFE (Teflon®) Gaskets. PTFE -based gasket materials are able to withstand significantly more aggressive chemical environments (including highly oxidizing environments) than standard Elastomer gasket materials. PTFE is principally used as a gasket material because of it's capability to remain unaffected by the majority of chemicals used in industry. PTFE/Teflon Gaskets Range Virgin grade PTFE (Teflon®) gaskets are made from 100% pure material which is used in most general applications. Filled PTFE (Teflon®) gaskets are made from PTFE which integrates additives and fillers in order to improve the performance of the gasket. Expanded PTFE (Teflon®) gaskets material is produced by expanding Virgin PTFE using a process that creates a uniform and highly fibrillated microstructure with equal tensile strength in all directions. Application Pumps, Mixers & Vessels, Filter, Heat Exchanger, Mechanical Seals, Flanges, Valves etc

...more

Teflon Bellow Seals

Teflon PTFE Bellow Seals are designed to handle highly corrosive liquids. PTFE Bellow seals are outside mounted with simple installation procedure and hence cost effective for corrosive media sealing. Teflon Bellow Mechanical seals has been designated as Fixed & replaceable bellow face respectively.For replaceable version there is flexibility for selection of face material as per the media to be sealed, which can be easily removed & replaced. Application used in acids, alkalis & extremely corrosive chemical ,Strong Oxidising and all corrosive services .

Size (Inches) : 16 mm to 100 mm

...more

Split Seals

Split Mechanical Seals are designed for the equipment where dismantling & assembly of the machine is difficult job. Split seals is a unique design with minimum components for assembling the seal and allow user to install the seal in minimum time.The multi spring design keep the faces uniformely in contact. The split seal face is balanced covered with split O-Ring as a sealing member. Slots provided in the housing facilitates fitting the seal on various equipments with different PCDs. in Split Mechanical seals Product leakage across the faces is minimized by maintaining rotor and stator face squareness with a robust, extended rotor assembly. Application ideal for paper mills, waste water treatment facilities, soda ash processing and light chemical plants.

...more

Slurry Mechanical Seals

we are offering slurry mechanical seals is doubled semi cartridge balanced seal, designed to operate without a flush in tough slurries. The slurry mechanical seals incorporates a unique non-clogging spring isolated from products.these are specially used for abrasive & media with solid particles. slurry seals suitable for liquids containing 30-40% slurry.slurry seals supplied with conical stuffing box and to be used as a replacement of double seal (back to back arrangement). available range: cartridge slurry seal, semi cartridge seal, single coil spring seal, multi spring slurry seals & non metallic pump slurry seals & split mechanical seals application : sealing of abrasive media is a big challenge in process industries. Our slurry seals designed to thrive in the harshest abrasive slurry environments process fluids such as ores, limestone, phosphates, kaolin clay, drilling mud, boiler fly ash, rock salt, sludge, sand and gravel .

...more

Slurry Mechanical Seals

We are offering a vast array of Slurry Mechanical Seals specially used for abrasive & media with solid particles. Sealing of abrasive media is a big challenge in process industries. Slurry Mechanical Seals are suitable for liquids containing 30-40% slurry. We provide Slurry Mechanical Seals with conical stuffing box and to be used as a replacement of double seal (back to back arrangement). These are specifically designed to thrive in the harshest abrasive slurry environments. Process fluids such as ores, limestone, phosphates, kaolin clay, drilling mud, lime mud, coarse coal, boiler fly ash, rock salt, sludge, sand and gravel are not at all a problem for these Slurry Mechanical Seals.

...more

Single Wave spring seals

Wave Spring seals are internally mounted which are non-clogging. Single Wave spring seals are designed for bi-directional and work with high viscous, abrasive media ,water, oils, fuels, low aggressive chemical substances and liquids containing solid particles. The spare parts are interchangeable without modification. seal faces are easily inserted. They can be designed in which spring is isolated from pump media.Torque transmission from retainer shell to seal ring is through drive pin. Application This type seals are Used in centrifugal pumps and High Viscosity Handling pumps in purification plants, pulp & paper, chemical, petrochemical and sugar industries, brewery and pharmaceutical applications

...more

Single Spring Mechanical Seals

Single Spring Mechanical Seals that we offer have open coil spring to work in contaminated fluids. These Single Spring Mechanical Seals feature very simple in design and can be manufactured for directional motions of shaft. Due to open coil spring, these Single Spring Mechanical Seals are used for non-clogging and self-cleaning operations. Further, these Single Spring Mechanical Seals are very economical and easy-to-use. These can be offered in variety of face combinations to suit most of the applications.

...more

Single Spring Cartridge Seals

Single Coil Slurry seals is a compact balanced seal specially developed for handling sludges, slurries, polymerising fluids and thick syrups containing 30-40% Single spring slurry seals have single coil spring construction & has a Non Clogging Spring Construction feature giving better seal life. Application Specially used in paper industries, petrochemicals, petroleum refinery etc

Speed : up to 15 m/s

Size (Inches) : 10 to 150mm

...more

Single Slurry Cartridge seals

Single Slurry Cartridge seals is engineered to operate in serve slurry environments eliminating costly external seal flushes. Slurry Cartridge Seals Features: Can handle axial compensation of about 1 mm Perfect design for standardization purposes Easily handle media containing abrasive particles and solids media Spring completely isolated from the product. Special elastomeric design to protect clogging Application Slurry Cartridge Seals is Design for the volume requirements associated with general mining processing duties. it contains robust primary and secondary seal face materials, making it the perfect general-purpose seal for slurry applications.

Size (Inches) : 38mm to 128mm

...more

Single Coil Unbalanced Seals

Single Spring Unbalance Seals is unbalanced single acting helical coil spring seals independent of direction of rotation. single Coil unbalanced seals are internally mounted and easy to install.rotary seal ring is driven by the motion transmitted by the shaft to the spring.slippages are eliminated, protecting the shaft and sleeve from fretting. Spring completely protected from the product.Easily handle for media containing abrasive particles and solids Application Specially used in paper industries, petrochemicals, petroleum refinery etc

Size (Inches) : 16 mm to 150 mm

...more

Single Coil Balanced Seals

Single Spring Balanced Seals especially designed to suit Slurry Media Sealing,light contamination, dirty media and clogging type application. This type also allows it to fit onto a normal shaft without any balancing step. The mechanical drive of this seal is realised by grub screw which lock onto the shaft. Balanced Single spring seals has a limited axial length, compact shape which allows easy mounting.Balance and unbalanced version can just be obtained by simply changing the carbon face assembled trough circlip provieded. Application High pressure pumps, refineries, fertilizers, nuclear plants and petroleum products. Material & Operating Limits

Speed : 1500 rpm (Max)

Size (Inches) : 10 mm to 150 mm

...moreSilicone Carbide seal faces

Silicon Carbide Seal Faces is the hardest seal face material with excellent abrasion resistance, high thermal conductivity and low coefficient of friction.It also retains its strength at temperatures as high as 1400°C and offers excellent wear resistance and thermal shock resistance. Silicon Carbide Seal Rings is an ideal seal face material for the refinery,fertilizer, petrochemical,chemical, and off-shore duties.

...moreSilicon Carbide Seals

Ceramic Seal faces have the property of good sealing properties,resistant-high-temperature,resistant-corrosion, and resistant-wearing. It is chemically inert and can be applied to nearly any product. Ceramic Seal Rings is the best seal face material for highly corrosive chemical services.We supply the High Alumina ceramic materials.

...more

Seals For O.E.M PUMPS

Available Range: Multi-spring double seal for ITT Flygt® pumps Wave-spring,balanced seal for Alfa Laval® SR and LKPL pump Elastomer bellows seals for KSB Pump Elastomer bellows seals for Grandfos Pump Rubber bellows seals for Grundfos ®® cp-series pumps. Conical spring 'O'-Ring mounted balanced seal for K.S.B ® movi series pumps. O'-Ring mounted seals for Alfa Laval® lkh series pumps flowserve® hydrotitan series pump seal flowserve® primotitan series pump seal flowserve® supertitan series pump seal Agitator Mixer seal for Alfa Laval® pumps single unbalanced seal for Alfa Laval® (SR serie,LKPL serie)pumps

...moreBe first to Rate

Rate ThisOpening Hours