Hydraulic Shaftless Mill Roll Stand

505,000 - 850,000 Per Set

1 Set (MOQ)

Roller Guide Box

Get Price Quote

06 Piece(s) (MOQ)

Roller guide box is used in hot rolling mill for entry of bar from one stand to another.

Best Deals from Milling Machine Accessories

INNOCENTI ROTARY TABLE

Get Price Quote

Innocenti Rotary Table 2500 X 2000 mm Used machinery sale rotary table innocenti 2500 Used Rotary tables machinery Second hand machines innocenti rotary Innocenti Rotary Table 2500 X 2000 mm Used machinery sale, Innocenti Rotary Table 2500X2000 mm, rotary table innocenti 2500, second hand machines innocenti rotary, Used Rotary tables machinery

Rotary Table

Get Price Quote

Its rotary indexer withwithout safety enclosure. It can be with ejection, leakbulb testing facility. PLC controlled with HMI operating.

Rotary Milling Table

15,000 Per Piece

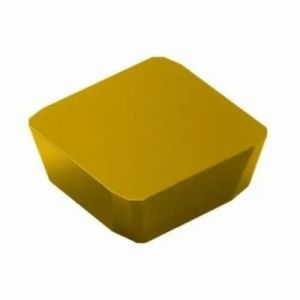

carbide milling insert

170 Per Piece

20 Piece (MOQ)

Carbide Milling Inserts

275 Per Piece

r390-11 t3 sandvik coromant coro mill 390 insert

8,600 - 17,200 Per pieces

1 pieces (MOQ)

2 Hi Skin Pass Rolling Mill equipment

Get Price Quote

for Bi-Mrtal Sintered Strip with Motorised Screw Down, Entry Guide, Pressure Pad, DC Thyristor Drive with speed Synchronised re-coiler

Mild Steel Milling Reduction Socket

1,500 Per Piece

End Mill Holder

2,480 Per Piece

Servo-Mechanical Indexer - SM Type

Get Price Quote

the sm series of indexers are servo-mechanical indexers designed for application where different output motions are required on the same table. These indexers provide highly accurate motion, with the added capability to move medium to heavy loads. Our preloaded cam & turret mechanism provides a zero-backlash solution for all your automation needs. The servo drive makes it freely-programmable. mechanism type: globoidal arrangement of shafts: crossed sizes: rt100-sm no. Stops: infinite (∞) since servo-driven index angle: freely programmable oscillating angles: freely programmable reduction ratio: 4:1 to 12:1 ratio option available max torque: 450 nm indexes/minute:

Roller Guide Box

15,000 Per Piece

1 Piece (MOQ)

"Hy-Tech Roll Mill Components CO." sister concern of Phenol Fibre Enterprises have continously been working with the design as well as the material in order to have the best tool for the guiding of long products. This has made our Roller Guide Box to be the BEST Our Roller Guides are trusted by major of steel producers for the following main reasons: 1. "Simple is better" it has been the key for success since the beginning of guides. 2. "Strong" Resistance to aggressive condition. 3. "Design" of roller holder allowing a spring action resulting in high stability of the roller guides. 4. "Adjustment" is easy access to all setting points. 5. "Material" used for our Rollers and other components are of Special Grades which have longer life. 6. "Custom" made guide arrangements to suit all typed of rolling. 7. "Spares" availability of complete guide system. 8. "Assistance" of qualified personal for guide setting and maintenance.

Slotting Attachment

Get Price Quote

Is of study design and is having adjustable stroke upto 3", useful for small keyway cutting.

Hitachi Milling Inserts

3,000 Per Pack

10 Pack (MOQ)

rotary indexing tables

Get Price Quote

The “Globoidal Cam Index Drives” are mechanical index tables which convert, continuous rotary input motion into intermittent, indexing output motion. The input shaft carries the Globoidal cam. This cam has a groove, which obeys the acceleration control “motion law”. The out put shaft carries the cam followers, which engage in the groove of the cam. The “motion laws” are designed to give a very smooth, jerk free indexing motion. Since the cam followers are pre-loaded against the cam, the backlash is practically zero. The index tables have large number of applications. They can be used in almost any automatic machine, which involves transfer of components on “rotary dial plate” or “linear indexing conveyor”.

Flour Mill Electric Motor

Get Price Quote

We are involved in offering a wide range of Floor Mill Motors to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.We introduce ourselves as an eminent trader and supplier of an extensive array of Floor Mill Motors. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.Features: Sturdy design Highly durable Application specific design

Milling Head Planer Machine

Get Price Quote

Description: All geared Milling Head, made of high grade stress-relieved C.I. Change gear system provides a 6 step spindle speed range and reduces the weight of the head Since changing of the cutter is not frequent in a Plano miller (unlike a milling machine), it is convenient to change the spindle speed through change gear pairs Spindle is provided with P5 Class Taper Roller Bearings (Total 4) + 1 Cylindrical Roller Bearing for rigid support Drive though ground splines in the spindle Gears, spindle, quill etc made of case hardening steel Case hardened & ground helical bull gear and mating gears for high torque transmission Spindle bearings lubricated for life with molybdenum sulphide grease Self contained, cam operated automatic lubrication system for gear box Accuracy: Spindle run-out on face, inner & out diameter: 0.01 mm Application: Increasing productivity by conversion of Planer to Plano miller. Single point tool cutting can be replaced by high speed, multi-point cutting by carbide cutters Cutting load is taken over by Milling Head reducing the load and speed of the table, thereby improving productivity and increasing machine life Accessories:Fixed Back Plate, Tilting Back Plate ±45º Right angle attachment: In combination with cross feed and vertical feed, adds floor boring capabilities to your converted Plano miller. The right angle attachment can be set to any angle ±360° allowing the user to machine all 4 sides of a rectangular job in the same setting

high frequency milling spindles

Get Price Quote

With an experience of more than 30 years in the field of machining spindles, GMN can today supply high speed spindles for machining centers. The spindles are suitable for both ferrous and non-ferrous machining. Spindles can be offered with both automatic tool change as well as manual tool change.

Rotary Table

65,000 Per Box

1 Box (MOQ)