Ultrafine Mill Machine

Get Price Quote

1 Piece (MOQ)

milling Machines

Get Price Quote

We market "SIGMA" brand Knee type Milling Machines: 1] 'SIGMA' Vertical Milling Machines 2] 'SIGMA' Horizontal Milling Machines 3] 'SIGMA' Universal Milling Machines Salient Features -: All Casting IS 210 grade FG 260 & stress relieved for sustained accuracyPower operated feeds & rapid traversesWide range of feed & speedsTable-slide with dovetail and cross-slide and knee-slide having flat guide-ways with taper wedges provide strength to withstand heavy cutting forces.Main spindle made of alloy steel hardened & ground and mounted on taper roller bearings ensure vibration free cutting.Gears are made of alloy steel & are hardened and groundCentral lubrication for guide ways and lead screwsSplash lubrication for main & feed gearingBuilt-in coolant-tankCoolant supply separate pump & motor through nozzles & fittingsBuilt-in chip removal & coolant collecting tray on base plate Standard Accessories -: Electric motors & electricalsSet of requisite toolsMilling arborInstruction & maintenance manualBuilt in chip removal trayCoolant systemMachine lamp Optional Accessories -: Universal dividing headVertical Milling headRack cutting attachmentSlotting attachmentRotary TableUniversal machine viceCollet chucks & colletsBacklash eliminator for climb milling.

Best Deals from Milling Machine

Close Type Sand Mill

Get Price Quote

1 Piece (MOQ)

Multi Mill Machine

200,000 - 600,000 Per Piece

1 Piece (MOQ)

Multi mill is a self contained portable unit useful for high speed Granulating, Pulverising, Mixing, Shredding, Chopping etc., a wide range of wet & dry materials without special attachments. As compared to the four common principles of size reduction, this machine utilizes the principle of variable force swing hammer blades having both knife and impact edges rotating with a carefully selected screen to control of reduction. Flow path of material in vertical rotor machine is streamlined. Duri ng, comminuting, material entering the chamber travels to the periphery and passes through the screen tangentially and radially a lo n g c h o kin g a nd rise in temperature.SPECIAL FEATURES All contact parts Ss304 / 316 / 316L AISI quality Machine rated for continous operation. High output with process uniformity. Direction of blade rotation by reversing switch. Various combinations of screens / speeds / number of blades / direction of rotation blade, can be selected. High screen opening area for higher throught. All contact parts can easily be dismantled and cleaned for change of product. Wide range of SS perforated and wire knitted screen available. Dust free operation. Additional perforated screen at the bottom of pulverizing chamber of eliminate higher percentage of fitness and control granule size more effectively and obtain higher outputs. Machine portable on castor wheels.

Hydraulic Shaftless Mill Roll Stand

505,000 - 850,000 Per Set

1 Set (MOQ)

CNC Milling Machine

Get Price Quote

Located in Mumbai(India), we are actively involved in bringing forth a high quality array of products in the market. Owing to our speedy distribution network, we are capable to render quickly and hassle free deliveries.

Universal Milling Machine

100,000 Per Piece

1 Piece (MOQ)

Multi Mill Machine

Get Price Quote

1 Piece (MOQ)

A traditional vertical rotor mill, suitable for granulation, pulverising, shredding, chopping etc. from dry and wet materials. Rotor has 12 blades with blunt and knife edges for hammering and cutting action and is easy to remove. Speed is variable and reversible. Output varying from 100kg to 800kg per hour depending on product and screen.

Ceramic Ball Mill Machinery

Get Price Quote

Sand Mill

Get Price Quote

Sand mills: are designed for the processing of high viscosity offset inks. the mill continuously processes the pre-dispersed printing inks in conjunction with an intermediate storage tank. the application specific design has been optimized for processing chocolate, paints, liquid printing inks, and pigments. Engineering and operating principles: continuously processes the pre-dispersed printing ink in conjunction with an intermediate storage tank, pre-selected parameters are held constant during the entire operational period guaranteeing that the best possible throughput rate is set.

Hydraulic Milling Machine

Get Price Quote

Geared Head Universal Milling Machines with chain drive, Longitudinal Auto Feed, Manual Cross & Vertical Feeds. Electric motor, Coolant pump, Manual Lubrication Pump. Vertical Attachment Head, Slotting Attachment, Rack Cutting Attachment, Dividing Head, Rotary Table, Milling Machine Vice, Collet Adapter, Collets.

End Mill Holder

2,480 Per Piece

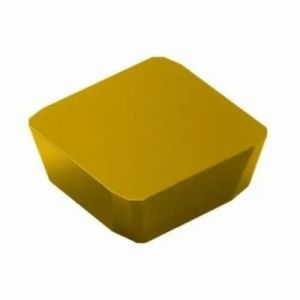

carbide milling insert

170 Per Piece

20 Piece (MOQ)

Milling Machine

Get Price Quote

We are offering Milling Machine. milling machine for babit metal line.

TATA Hitachi Excavator

Get Price Quote

Excavator Operator Training Simulator - TecknoSIM

2 - 10 Per piece

TecknoSIM Excavator Operator Training Simulator is fully functional simulator for training new and experienced operators in a risk-free environment. It is a realistic replica of a actual equipment with accurate dynamics that provides the trainees a safe environment to refine their skills as well as improve their productivity & efficiency. Excavator Simulator enables training on a range of scenarios that allows operators to practice safely on mining operations as well as potentially life-threatening emergency scenarios. New operators learn to operate a shovel safely on a simulator before operating the real equipment whereas experienced operators get a chance to further improve their skills. TecknoSIM simulators are versatile and scalable to every training need and budget. The comprehensive training tools inbuilt in the simulator provides the most updated skills required.

All Geared Universal Milling Machine

Get Price Quote

This is a precision all geared universal & vertical milling machine with hardened and ground head stock gears. The machine offers 18 automatic table feeds and 2 rapid feeds with 12 spindle speeds ranging from 40 to 1120. The machine is supplied complete with electric motors, control panel, arbor and bushes. Optional equipment avail. includes Vertical attachment, Ram type vertical head with independent motor, rack cutting and slotting attachments, machine vice, rotary indexing table, universal dividing head, electric coolant pump with fittings, ISO 40 milling adaptor and machine lamp.The machine is available in four table sizes (in mm): 1270 x 280, 1400 x 330, 1600 x 355 and 1800 x 400mm.

Gantry Based Machine

Get Price Quote

Dual driven gantry type versatile cnc system for all your plate profile cutting needs. Rugged construction of panther makes it extremely suitable for plasma oxyfuel cutting with multiple cutting heads.

communiting mill

Get Price Quote

Working: It consists of the box type chamber containing fixed blades which rotate at different speeds to break the material in to finer particle sizes. The product is input to the feed pan which takes it to the inlet and there by to the box type chamber. The chamber contains fixed rotor blades which rotate at designated speed to achieve the required particle size. The appropriate screen of the required mesh size is placed underneath allows the material sizes achieved to pass through and the rest are again ground till the come of specified size. Optional Features : Flame proof motor with electrical fittings Castor wheels with brakes Salient Features : Sturdily built construction and its unique design meet the requirements of best pulverizing and granulation The design of its comminuting mill speaks the glory of it by outdating the reversible comminuting chamber models which employs more manpower and risk to do the same. Chamber assembly and contact parts are made of SS 316/S.S. cladding. Openable chamber wall and the blade loss with sixteen fixed blades Shaft is provided with too many components on it and instead, the rotor acts as the driver with unique drive arrangement, which ensures less wear and tear resulting in easy maintenance. Different types of meshes from 4 meshes to 200 meshes can be provided to suit the application Machine is mounted on high quality S.S. pipes and castor wheels The motor is mounted on solid hard chrome plated rails for easy movement by a hand wheel The hopper with covers is mounted on the comminuting chamber to lead the product into the chamber Steps are provided for proper mesh fitment and hence assure longer life The control panel board mounted on the base plate is provided with star-delta starter for comminuting dual speed motor with proper protection.

Sweden Vertical Milling Machine

Get Price Quote

We are offering sweden vertical milling machine. Made in sweden. Table size 1200 x 300 location - bhavnagar , gujarat , india.

Milling Machine

Get Price Quote

We are considered as prominent Milling Machine Exporter, Importer and Supplier in Mumbai. Our Milling Machine is checked over various parameters before sourcing it from the vendors. These parameters are as follows: performance, durability, corrosion-resistance, cost-saving, etc. We can cater to the bulk requirement of Milling Machine for several industries. We offer wide range and sizes of Milling Machines i.e. Horizontal, Vertical, Universal, Turret type, Bed Milling, Planner and Plano Milling, Thread milling, Rotary Milling, Key Way Milling, etc. Details : Make : GraffenstadenModel : FB830SD8Location : Navi MumbaiStock : STK0001436Origin : France Technical Specifications : Table Size : 3600mm x 800mm

Mild Steel Milling Reduction Socket

1,500 Per Piece

Rotary Table

Get Price Quote

wmw union 2000X1900 mm rapid feed Rotary Table Rotary Table wmw union 2000X1900 mm with rapid feed wmw union 2000X1900 mm Rotary Table wmw union 2000X1900 mm with rapid feed Rotary Table

Dental Spoon Excavators Double Ended

Get Price Quote

100 Piece (MOQ)

Roller Guide Box

Get Price Quote

06 Piece(s) (MOQ)

Roller guide box is used in hot rolling mill for entry of bar from one stand to another.

Rotary Table

Get Price Quote

Its rotary indexer withwithout safety enclosure. It can be with ejection, leakbulb testing facility. PLC controlled with HMI operating.

All Geared Universal Milling Machine

Get Price Quote

High Quality Close grained cast Iron. All slides Grinded on Slide way Grinder and Closely scraped. Steel Sliding gears carried on splined shafts, shafts Spindle and Arbor made of alloy steel hardened and ground.

Comminuting Mill

Get Price Quote

These are available in various sizes including lab model. During the manufacturing process our professional take great care. This product is availabel with performation and also in wire mesh design.This product is made available as per the requirements of customers.

rolling mill machine

Get Price Quote

With organized understanding of the respected market, we are offering an inclusive collection of Rolling Mill Machine. These products are developed using optimum-grade material and contemporary technology by dexterous personnel. In tune with miscellaneous needs and demands of our customers, these products are customized in numerous specifications. For Quotation kindly specified below things:- Strip Material Thickness Minimum and Maximum Width Minimum and Maximum Strip Coil weight Strip ID and OD Features: Durability High strength Rugged

End Mill Sharpening Machine

Get Price Quote

Easy operation, precision grinding and cost saving.Hand held for easy movement to operate safely in every environment.Precision, Efficiency, Easy Operation, Short Processing Time