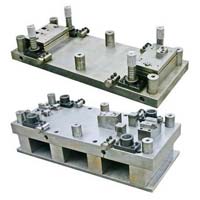

Aluminium Die Casting Molds

Get Price Quote

Designed to withstand adverse effects of abrasion and moisture, our Aluminium Die Casting Molds are of immaculate quality. Our company’s name figures in the list of prominent Manufacturers, Suppliers and Exporters of Aluminium Die Casting Molds from Maharashtra. The Aluminium Die Casting Molds we make available are manufactured in accordance with international quality standards and norms. We are capable of delivering bulk orders of the Die Casting Molds within stipulated time.

shell moulding

Get Price Quote

ell molding, also known as shell-mold casting, is an expendable mold casting process that uses a resin covered sand to form the mold.Shell moulding is similar to sand moulding except that a mixture of sand and 3-6% resin holds the grains together. Shell moulding also uses sand with a much smaller grain than green-sand. Set-up and production of shell mould patterns takes weeks, after which an output of 5-50 pieces/hr-mould is attainable. Aluminium and magnesium products average about 13.5 kg as a normal limit, but it is possible to cast items in the 45-90 kg range. Shell mould walling varies from 3-10 mm thick, depending on the forming time of the resin.Shell moulding is used for small parts that require high precision. Some examples include gear housings, cylinder heads and connecting rods.It is also used to make high-precision moulding cores. Compared to sand casting this process makes complex parts be cast with better dimensional accuracy, a higher productivity rate, and lower labor requirements. less labor. There are a dozen different stages in shell mould processing that include: 1. Initially preparing a metal-matched plate 2. Mixing resin and sand 3. Heating pattern, usually to between 505-550K 4. Inverting the pattern 5. Curing shell and baking it 6. Removing investment 7. Inserting cores 8. Repeating for other half 9. Assembling mould10. Pouring mould11. Removing casting12. Cleaning and trimming.The sand-resin mix can be recycled by burning off the resin at high temperatures.

Best Deals from Mold Castings

FERROUS METAL SHELL CASTING

Get Price Quote

Shell mold casting allows the use of both ferrous and non-ferrous metals, most commonly using cast iron, carbon steel, alloy steel, stainless steel, aluminum alloys, and copper alloys. Typical parts are small-to-medium in size and require high accuracy, such as gear housings, cylinder heads, connecting rods, and lever arms.

aluminium pressure die casting mould

Get Price Quote

aluminium pressure die casting mould, Plastic Mould, Motor Components, Gears

shell mould casting

Get Price Quote

shell mould casting, Pipe Fitting, pipe fitting casting, compressor casting

Permanent Mold Aluminum Castings

Get Price Quote

Permanent Mold Aluminum Castings, Permanent Mold Aluminum

Shell Core Casting

Get Price Quote

Shell Core Casting, precision cnc machining, High Precision Tractor Shafts

Aluminum Bottle Casting Molds

Get Price Quote

Aluminum Bottle Casting Molds, automotive plastic molds, aluminum molds

Aluminum Casting Moulds

Get Price Quote

Aluminum Casting Moulds

Aluminium Casting Moulds

Get Price Quote

Aluminium Casting Moulds, Aluminium Injection Mold

Green Sand Mould Casting

Get Price Quote

Green Sand Mould Casting, shell mould casting

shell moulding

Get Price Quote

shell moulding, carbon steel, rubber mixing mill rolls, Rolling Mill

Green Sand Moulding

Get Price Quote

Green Sand Moulding, Bronze Bearings, split bearings, brass bearings

permanent mold casting

Get Price Quote

permanent mold casting