Customized Rubber Molding Services

3,400 - 6,000 Per Each

4 Pieces (MOQ)

Are you on the lookout for a trusted company that provides Customized Rubber Molding services? If your answer is a yes, we are the right choice to opt for. We provide Customized Rubber Moldings for all kinds of metal-bonded products. We have seasoned professionals who use the latest Rubber Molding techniques in order to fulfill varied requirements of the clients. We have benefitted thousands of clients with our Customized Rubber Molding services and the next one could be you.

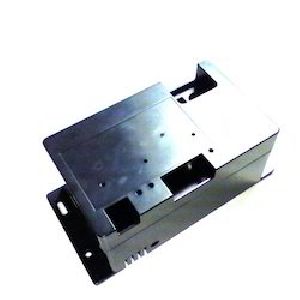

Plastic Welding Machine

550,000 Per piece

1 piece (MOQ)

As a joining process for industrial thermoplastics, the ultrasonic method is very well proven in practice. Particularly in the production of mass- produced parts, the process offers definite advantage over previous methods such as for instance high strength, clean weld seams, fast processing times, extremely low rejection rates and low energy consumption.In addition to its main application which is welding of moulded thermoplastic parts, this technique can be used successfully for riveting, forming, stacking as well as embedding of metal parts into thermoplastic materials.

Looking for Molding Services Providers

Plastic Injection Molds

32,000 Per piece

1 piece (MOQ)

Plastic Injection Molding Machines

Get Price Quote

1 piece (MOQ)

Hot Runner Mould

Get Price Quote

Euro Tech Hotrunner System has carved a niche for itself in the global markets as a successful Manufacturer and Exporter of Hot Runner Mould. Backed with years of industry experience and market understanding, we are offering a wide gamut of Hot Runner Mould that is manufactured with advanced technology and using supreme grade raw materials in sync with international quality standards. Features : 16 cavity White Cap Side Gate

Metal Injection Molding

Get Price Quote

We are offering metal injection molding—mim—offers a manufacturing capability for producing complex shapes in large quantities. The process utilizes fine metal powders (typically less than 20 micrometers) which are custom formulated with a binder (various thermoplastics, waxes, and other materials) into a feedstock which is granulated and then fed into a cavity (or multiple cavities) of a conventional injection molding machine. After the “green” component is removed, most of the binder is extracted by thermal or solvent processing and the rest is removed as the component is sintered (solid-state diffused) in a controlled-atmosphere furnace. The mim process is very similar to plastic injection molding and high-pressure die casting, and it can produce much the same shapes and configuration features. However, it is limited to relatively small, highly complex parts that otherwise would require extensive finish machining or assembly operations if made by any other metal-forming process. Advantages: the advantages of the metal injection molding process lie in its capability to produce mechanical properties nearly equivalent to wrought materials, while being a net-shape process technology with good dimensional tolerance control. Metal injection molded parts offer a nearly unlimited shape and geometric-feature capability, with high production rates possible through the use of multi-cavity tooling. Materials range the metal injection molding industry can manufacture an extremely wide variety of metal alloy compositions for use in your application. The alloy families shown below make up a broad representation of the spectrum of alloys which can behave been produced for various applications. If you do not see the exact alloy or alloy family shown on our extensive list in which you have interest, please contact your supplier in order to see if the alloy or a substitute alloy is available. Working closely with your supplier will enable you to find the best solution for your application. The most common alloy families are: iron, low-alloy steels, stainless steels other alloys: aluminum alloys, bio-compatible alloys, carbides, ceramics, cobalt-based alloys, controlled-expansion alloys, copper and copper alloys, hardmetals, heavy-metal alloys, magnetic alloys (soft and hard), nickel-based alloys, precious metals, reactive metals, shape-memory alloys, specialty alloys, titanium and titanium alloys, tool steels.

Plastic Molding Services

Get Price Quote

Molding is used to give desired shape to plastic and synthetic materials using different molding processes and is extremely popular method of manufacturing plastic parts and components for all kinds of applications. We understand the importance of the plastic part / component in their respective industry and hence choosing the right materials for the job is the most crucial step of the plastic injection moulding process cycle. We use Polythene, Poly-carbonate, Acrylic, Polyamide, Polystyrene, Polypropylene (PP), Acrylonitrile Butadiene Styrene (ABS) and Polyester materials. Thermo Plastic Thermo Set Rubber

Electronics Part Moulding Service

Get Price Quote

Located in Mumbai (Maharashtra, India), Mould Tech India can be approached to provide best-in-class electronics part moulding services to the clients. Ours is a team of persistent electronics part moulding experts, who have in-depth knowledge of all the major techniques and operations involved in this process. These experts have done all these operations in a safe and secure manner before as well. Connect with us now and avail our services.

Plastic De Dusting Machine

Get Price Quote

1 Piece (MOQ)

Ultrasonic Plastic Welding Machine

Get Price Quote

Our company is capable of delivering consignments on time owing to an efficient trading network we have. Our range of products is manufactured under the administration of qualified quality control executives by using optimum supplies and ultramodern technologies.

Injection Molded Rubber Parts

250 - 3,000 Per Piece

1 Piece (MOQ)

We are the Manufacturers & Exporters of Antivibration Machine Rubber Pads and various Industrial Rubber Products.

(LTV) Low Temperature Rubber Moulding Service

Get Price Quote

Based in Mumbai (Maharashtra), 3 D Vision Cad Cam Services specializes in rendering one of a kind low temperature rubber moulding service. We provide low temperature rubber moulding customization services to clients with different preferences. We can conveniently customize rubber moulding exactly as per the specifications of the client. We are well-versed with the intricacies of rubber moulding customization and manufacturing, thus the moulds customized by us look amazing with our finishing touch.

Plastic Molding Machine

Get Price Quote

We have a well-developed all the in-house storage facility, laced with all the modern facilities. Also, we have hired a team of professionals who efficiently manage and maintain it. As we are acknowledged for providing high quality products to the clients, we make use of only superior grade raw materials as inputs. The selection of raw material is done by our experts.

Injection Moulding Machine Repairing

Get Price Quote

We are dedicated to plastic industries. Retrofitment and reconditioning for any type injection moulding machine with new plc and hy brid servo system.

Custom Plastic Molding Service

Get Price Quote

Ours is a professionally managed firm actively involved in providing dependable solutions related to plastic moulding. We are operating from Mumbai (Maharashtra, India). With a wealth of modern processing techniques and quality workforce, we are capable of furnishing standard as well as tailored requirements of clients. With our services, we first understand clients’ requirements related to material, product, grade and budget, then work accordingly. To know more about us and our services, get in touch with us.

Plastic Injection Moulds

Get Price Quote

We manufacture and supply Plastic Injection Moulds of precise make. Materials such as Polystyrene, Nylon, Polypropylene and Polythene can be used in a process called Injection Moulding. These materials have thermoplastic properties, which means when they are heated and pressured in a mould they can be formed into different shapes.

Plastic Injection Moulds

Get Price Quote

Over the years, we have gradually built up a comprehensive base of product specific know-how in the fields of medical, pharmaceuticals, laboratory equipment, specimen containers, cosmetics, packaging, caps and closures, cutlery, spoon, fork, knife, home appliances, writing instruments, pen, ballpen, sketch pen, electrical, electronics and industrial parts for which we manufacture plastic injection molds, moulds.

Plastic Blow Molding Machine

Get Price Quote

Plastic Blow Machines: blow Molding Machines from 0.5 - 2000 Ml mini Blow Models (100 & 200 Ml) bottle Neck Cutting / Trimming Machine single and Double Station Models with Option of Double Heads. plc Based Controls Optionally Available we Offers Blow Molding Machines from 0.5 - 2000 Ml Mini Blow Models (100 & 200 Ml) Bottle Neck Cutting / Trimming Machine Blow Molding Machines Available in Fully Pneumatic/ Hydraulic Types, Single and Double Head Option, Direct and Toggle Clamp Models. We Collobrate with Customers to Provide for Special Purpose and Application Machines. We Develop Blow Molds as per Your Design/ Drawing / Sample Provided. Apart from Manufacturing Plastic Machineries We Undertake Development and Give Production of Tailor Made Plastic Blow (from 0.5 Mls) & Injection Molded Articles.

Customised Industrial Moulding Service

Get Price Quote

Established in 2000, PP has acquired an admirable position in the industry owing to its scheduled operations and cost-effective molding solutions. We are operating from Mumbai (Maharashtra, India) and providing personalized solutions for industrial molding needs. In order to process quick molding needs of the clients, we have developed our own facility. So, share your specific needs, we assure to provide appropriate solutions accordingly.

Moulding Services

Get Price Quote