Liquid Pump Moulds

Get Price Quote

Our company offers a range of well-designed Liquid Pump Moulds. The range of Liquid Pump Moulds made available by us is designed as per the requirements of different manufacturers. The range of efficient Liquid Pump Moulds offered by us is resistant to long periods of use. The company quotes the best prices for Liquid Pump Moulds in India. Highlights : Well-designedLow maintenanceCompetitive pricesEasy to use

Two Plate Injection Moulds

149,000 - 150,000 Per Piece

Best Deals from Molds

stretch blow moulding

Get Price Quote

PET packaging requires new technical solutions every day in the constantly changing world of plastic packaging. We are ready to satisfy the specific needs of each client with solutions that are specific to each case, attentive to every detail. To make you easier to find which of our blowers PET preforms best fits your needs, this comparative table will give you clarity. Please send us request via adjacent form for more information to help you on best option to suit your need.

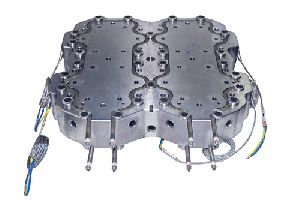

hot runner mould

Get Price Quote

Euro Tech Hotrunner System has carved a niche for itself in the global markets as a successful Manufacturer and Exporter of Hot Runner Mould. Backed with years of industry experience and market understanding, we are offering a wide gamut of Hot Runner Mould that is manufactured with advanced technology and using supreme grade raw materials in sync with international quality standards. Features : 16 cavity White Cap Side Gate

guficol 2miu injection

750 - 800 Per VIAL

25 VIAL (MOQ)

Guficol 2MIU Injection is an antibiotic that fights bacteria. It is used to treat severe bacterial infections of the body. It is commonly used for critically ill patients admitted to the hospital.

Concrete Cube Mould

900 Per

300 Piece (MOQ)

Rubber Mold

Get Price Quote

Manufacturers of Antivibration Machine Mounts & Rubber Molded Products and Parts

Plastic Die Casting Molds

Get Price Quote

We undertake Plastic Molds manufacturing as per specific requirements given by the clients. These Plastic Molds are used for making various plastic products such as bottles, caps, auto parts, etc. Catering to the requirements of various industries, these Plastic Molds are known for their attributes such as superior strength, durability and high performance. The variety of Plastic Molds that we provide is appreciated for dimensional accuracy, high strength and durability. Highlights Dimensionally accurate High strength Durable Non-corrosive

injection moulding moulds

1,000,000 - 10,000,000 Per piece

Kindly attn:- Owner / Chairman / Director / Managing Director / Authorised Purchase Head.Dear Sir,We are mfg of new moulds and Are Sole Agents for sales and services provider for Indian market with Dealing of New Injection Moulding Machine Range from 100T to 4000T with having excellent quality and at most competitive reasonable prices & More Beneficiary for the exporters of finished goods.Machinery suitable for Injection Moulded products as for below1.Automobiles2.Battery case3.Furniture and crates4.Caps & Closures5.Computer & Accessories6.Household7.Electrical & Electronics8.Engineering9.Food & Non food containers10.Medical labs11.Paint pails12.Lubricants13.Pet performs14.Pipe fittings15.Textile16.Thin wall containers17.Writing instruments stationery18.Houseware & KitchenwareAnd having all ancillary equipment for support of injection,blow and extrusion plant machinery to run in automation are as1.Hopper & Dryer2.Auto loader3.Mould Temperature Controller (MTC)4.Granulator5.Colour Mixer6.Chiller7.Cooling Tower8.Robot 9.Cleaning Agent for Complete plant water system10.Hotrunner & Controller11.Preventive Maintenance for moulds & machinery12.Annual Maintenance Contract Pls to let us know the exact requirement of machinery1.What kind of product and raw material uses2.What capacity of machinery in Tonnage3.Total Shot weight4.Maximum Mould Size (L x W x Ht)5.Type Toggle or Hydraulic6.Min & Max Cycle time 7.Require Fixed pump or VDP or Servo8.How many quantity of Machinery require in nos. 9.Do you require New Moulds & design ready avail10.How many quanity new moulds require in Nos.11.Robot Require12.Require Ancillary equipment If any requirement pls feel free to provide us your valuable reply with appointment and contact name & numberAnd business visiting card. We provide complete services mfg for plastics industries from Plastics product to moulds to plastics machinery .Most Welcome Proposal for franchises partners & Investors & Buyers at State , district.Awaiting for your valuable feedback for project plan of purchase of capital goodsThanking youFor Ampees EnterprisesNeha -Marketing

Frp Moulding

Get Price Quote

We are recognized as one of the eminent fabricated frp canopy, frp moulding manufacturers in india. The use of optimum quality materials in the manufacturing of the frp canopy ensures high durability, tensile strength and resistivity to adverse conditions. Various industrial sectors are placing repeated orders for the non corrosive frp canopy as no alternative is available in terms of quality and performance. Moreover, we are manufacturer of various types of leak proof frp canopy guards which is available in different sizes and colors as per your requirements. Applications • frp canopy for electrical motor • canopies push button station • instrumentation transmitter - canopies and boxes • local control station(push button station) • pole boxes (street light junction boxes) • junction boxes specification sheet for frp motor canopy guard sr. No. parameters specifications 1 material of construction frp 2 shape & size as required 3 type of resin isopthelic fire retardant and non fire retardant

Moulded Thermocol Box

220 - 250 Per Kilogram

1 Container (MOQ)

Injection Moulding

Get Price Quote

We, Vikas Industry, produce best quality injection molded parts, also keeping in mind timely delivery and customer's requirements. We are leading manufacturer's of plastic injection molds in India. Injection molding, in a simple language is high pressure injection of Thermo plastic raw material into a mold to make it as a required shape. Molds are made up of stainless steel. These products vary from few grams to 2 kgs. Injection moulding is a manufacturing process for producing parts by injecting material into a mould. Injection moulding can be performed with a host of materials, including metals, glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers. Material for the part is fed into a heated barrel, mixed, and forced into a mould cavity, where it cools and hardens to the configuration of the cavity. After a product is designed, usually by an industrial designer or an engineer, moulds are made by a mould maker (or toolmaker) from metal, usually either steel or aluminum, and precision-machined to form the features of the desired part. Injection moulding is widely used for manufacturing a variety of parts, from the smallest components to entire body panels of cars. Advances in 3D printing technology, using photopolymers which do not melt during the injection moulding of some lower temperature thermoplastics, can be used for some simple injection moulds.

Thermocol Moulding

Get Price Quote

We offer customized and high quality thermocol moulding with remarkable features. We offer thermocol moulding in different shapes and sizes which fit different packaging requirements. Our thermocol moulding is quality tested by experts. Further, we are a leading manufacturer and supplier of thermocol moulding. attributes : available in different sizes and capacities excellent quality economical

wetcast paver moulds

Get Price Quote

By making use of quality packing material, we are able to ensure that the orders will remain free from damage during transit. Also, our expert packing personnel strictly check the entire lot before final dispatch. We are working with an aim of making available flawless lot of products and for this; we check the product quality on several grounds.

custom plastic molding service

Get Price Quote

Ours is a professionally managed firm actively involved in providing dependable solutions related to plastic moulding. We are operating from Mumbai (Maharashtra, India). With a wealth of modern processing techniques and quality workforce, we are capable of furnishing standard as well as tailored requirements of clients. With our services, we first understand clients’ requirements related to material, product, grade and budget, then work accordingly. To know more about us and our services, get in touch with us.

Dies & Moulds, Injection Blow Moulds, Press tool Dies, Fixtures, Machine Tool Maintenance

Get Price Quote

Machine Tool Engineers estd in the year 1996 is a proprietorship company based in Mumbai engaged in Machine Tool Manufacturing, Dies & Moulds, Injection Blow Moulding ,Special Purpose Machines Rebuild and Repairs & all types of Machining work

Plastic Moulding Inserts

Get Price Quote

sycamore specializes in manufacturing of metal inserts for plastic moldings used especially for automobile interiors, trims, under-hood covers and other plastics. Sycamore provides insert solutions right from conceptualization stage all the way to volume production. Offering a wide variety of inserts with different types of knurling profiles which help hold the inserts in place in line with the design.our molding inserts come with our leading edge engineering services which include design engineering and feasibility studies.

Injection Moulds

Get Price Quote

We offer wide range of Injection moulds for different product applications: Moulds for household items like buckets, bowls, basins, mugs etc. Moulds for houseware / furniture / pallets / crate Moulds for turnkey project – PET preform / Thinwall IML system / Caps & closure systems / Audio-video-CD / Ball point pens Moulds for Home appliances Moulds for PVC fittings Moulds for auto-components

Plastic Ice Candy Mould

349 Per Piece

10 Piece (MOQ)

Simple to you : You don't need an ice cream making machine to prepare frozen ice cream, It is very easy to making ice cream, just fill the molds, maker with the required ingredients and keep it in the freezer, this mold, maker prepares 8 key type ice candies, creams at a time Material : Made in India product with 100% Food Grade & BPA Free material. Because for us, your health is the most important requirement. This feature also helps reduce waste with an eco-friendly, reusable design. Multiple Uses : It can be used over and over again to make all-natural large frozen treats such as juice, yogurt with fruit and anything you like. No More Sticky Hands these ice cream molds are designed to make drip-free ice creams and give a clean, no-mess experience. Molds keep your fingers and clothes free from sticky drips

Wooden Mouldings

Get Price Quote

We also manufacture ready to use door frames from no. of species of wood i.e. teakwood, red Meranti, burmateak, & pinewood as per the requirement of the client. The door frames are made with precision through sophisticated modern machinery, which helps us in giving the door frames a superior finish & strength. Our frames are mainly supplied to professional builders throughout india.

Tray Brush Molds

Get Price Quote

Thermoplastic Molds

Get Price Quote

Our mould system guarantees perfect frame with runner to direct the uniform flow of molten thermoplastic with cooling channels working in unison to control temperature and ejection system to provide finished moulded product of high quality. Marching ahead with the technological advances, we are adopting a new symbol reflecting moulds special characteristics of quality performance and master in Injection Moulding

Automatic Injection Moulds

Get Price Quote

segmented molds

Get Price Quote

1. Two Piece Molds 2. Segmented Molds 3. Bladder Moulds 4. Container Moulds

Plastic Injection Mould

8,000 - 9,000 Per Piece

Blow Moulds

Get Price Quote

rubber molding

Get Price Quote

RUBBER MOLDING CAPABILITIES COMPRESSION MOLDING The most popular molding process, compression molding uses pressure and heat to mold the rubber into the shape required. Compression molding is a good manufacturing choice for large parts, parts that do not require tight tolerances, and low production quantities. It requires inexpensive tooling, but is a labor-intensive process with longer loading and process times than other molding methods. Compression molding press capabilities for our compression line range from 12” x 12” on the low end, up to and including 85” x 108” on the high end, with various press sizes in between. TRANSFER MOLDING Rubber transfer molding uses a process similar to compression molding, but has a transfer system on the top of the mold that feeds the rubber into multiple mold cavities when the press is closed. This allows for more efficient processing – tool and material loading times are reduced. It is used for large parts, parts that do not require tight tolerances, and higher production runs than compression molding. Minor Rubber’s transfer molding press capabilities for our compression line range from 12” x 12” on the low end, up to and including 85” x 108” on the high end, with various press sizes in between. INJECTION MOLDING With injection molding, rubber is pre-heated before being injected into the mold. Since it is pre-heated, the rubber flows more readily into the mold, allowing for higher cure temperatures, shortening the curing cycle. Injection molding presses provide tight clamping, which results in little or no flash. Parts manufactured using injection molding may not require additional finishing. The process is used for high production runs and parts that require tighter tolerances. Our injection press capabilities range from 24” x 24” up to 48” x 72”, with tonnage (clamping force) of 100 to 500 tons. Our facilities are fully equipped with state-of-the-art equipment and managed using the latest technologies. With production facilities located in the United States, we have the flexibility and capacity to manufacture your parts efficiently and economically, while meeting the highest quality standards. RUBBER EXTRUDING Rubber extruding services for a variety of industries. Our rubber extrusions include profiles and tubing, cut washers, and gaskets. With our state-of-the-art manufacturing facility, we provide extruded rubber manufacutring for a range of products, including: Vulcanized spliced gaskets Gaskets with molded or injection molded corners Simple and complex shaped seals, washers and gaskets Strips, cord and seals in long lengths on reels or coils, or as cut lengths Tubing and profiles in long lengths on reels or coils, or as cut lengths Holes, notches, and special cut-outs can be fabricated into our extruded products Tubing and Cord sizes range from 1/32” I.D. up to 7” O.D., and wall thicknesses as thin as .040”. Profile shapes can range from .125” square up to and including 8” square. Wall thicknesses on extruded profiles, like tubing, can be as thin as .040”, but will depend on the shape of the cross section. APPLICATIONS Automotive Power Generation Petrochemicals Fluid Power Instrumentation Chemicals & Fertilizer Plants Electronics Filtration Pharmaceuticals Hydraulic Fittings Hydraulic Cylinders Pneumatic Cylinders Valves and Pumps Plumbing Products Dairy/Food Processing Earthmoving & Construction Equipment

Hair Comb Mould

50,000 Per Piece

plastics injection molding

Get Price Quote

Using their years of experience and an advanced machining facility, ERIKS manufactures inhouse every type of final product. Starting from a sketched design, ERIKS manufactures plastic parts fully to specification. Flexible manufacturing allows the number of parts produced to vary from ones and twos to many thousands.

Plastic Moulds

Get Price Quote

For customized requirements / latest designs for the market and better productivity of moulds we have introduced "Enjay Dies & Moulds" a brand under which mould design & development services are provided to plastic manufacturers looking to fabricate moulds as per their specific requests. The company has built its reputation and credibility through consistent delivery of quality, innovation and value We have made our presence felt both in the domestic and international market and have developed a reputation based on quality and workmanship. The Company uses the latest machinery With advanced CAD/CAM/CAE systems such as Pro-Engineer, Solid works, Auto CAD, in mold design we can offer drawings in latest formats to manufacture quality moulds.