mold bases

Get Price Quote

We offer a wide range of Mold Bases in various sizes and materials, which are considered apt for prototype moulding. These mould bases we offer can be used for a wide range of applications in the automotive, pharmaceutical and machinery manufacturing segments. We are a manufacturer and supplier of high repute and reliability of premium quality mold bases from Mumbai, Maharashtra, India.

Molded Rubber Component

10 - 500 Per Piece

100 Piece(s) (MOQ)

Best Deals from Mould Components

Parting Lock

10 - 50 Per Piece

Rubber Components

Get Price Quote

We are engaged in manufacturing and supplying of precisely designed Rubber Components. The Rubber Components offered by us are widely used in automobile industries for various applications. Fabricated using finest quality rubber, the Rubber Components offered by us have been widely appreciated by the customers. Moreover, we offer the Rubber Components at pocket friendly prices. We Offer : VitoneNBRNatural rubberSynthetic rubberE.P.D.MC.RS.B.RSilicone

Molded Rubber Components

Get Price Quote

Only quality packing material has been used for the packing of the products. Customers can stay rest assured for the safe delivery of the orders as our experts keep a vigil eye on the entire procedure. As we give utmost importance to the quality of the products, we produce them in accordance to the quality standards. Features: Durable Specifically designed Non-corrosive Size: customized as per clients

Rubber Components

Get Price Quote

We are also one of the leading manufacturers of Rubber Components in various grades of rubber like nbr, Nitrile, Neoprene, epdm, Butyl, Hyplon, Silicon, Polyurathin, Viton, etc., confirming to quality requirement of customers against b.s & i.s standards. We produce various components such as diaphragms, butterfly valves seats, rubber lined & moulded flaps, oil seals, lip seals �u� ,�v�, & �o� rings, gaskets, bellows, anti vibrators, rubber sheets, bellows, chevron packing seals, canvas buckets etc., as per needs of customers for their, temperature, pressure, resistance etc., as per needs of various applications. At this stage we are supplying our products to cement, sugar, steel, marine, valves oil refinery, chemical, fertilizers, pharmaceutical, food, pump, automobile industries etc., to fulfill the requirements of our customers we have up to 80� x 80� diameter moulding capacity hydraulic press & in step moulding maximum possible on customer requirement. To control the product quality, we have in-house die manufacturing unit. Also it helps to fulfill the timely or urgent delivery requirement of customer. We have precision measuring instruments in our tool room to maintain the dimensional accuracy. These instruments are calibrated periodically. Also, to ensure rubber quality & its properties to suit desired application, we do laboratory test for each batch from govt. approved lab like irmra in India. We have an aim on entire satisfaction of our customers, and for that we always welcome our customers with their specifications, drawing and if possible with samples. Download

rubber molded component

250 Per No

we are the leading manufacturers & exporters of Antivibration Machine Mounts and Industrial Rubber Moulded Products.

Injection Moulded Components

100 Per Piece

3000 Piece(s) (MOQ)

We are a trusted name in manufacturing plastic moulded components for various engineering industries Pan India.. We are capable of processing all types of thermoplastics from consumer plastics like LDPE, HDPE, PP to various engineering plastics like Nylons, ABS, PC, PC- ABS Alloys, Noryl, Polyurethanes etc. We develop & offer parts for domestic appliances , Custom designed enclosures for electronic equipments , speaker fronts , Luxury household goods

Slide Retainers

100 Per Piece

Plastic Moulded Components

Get Price Quote

In this N2 gas at low pressure is utilized to apply uniform pressure on molded plastic parts. N2 gas can come in contact with melts at high temperature without difficulty. The principle of this process is that nitrogen gas is injected, during the moulding cycle, either through the sprue or directly into the mould tool. At a controlled high pressure this has the benefit of overcoming sink marks or introducing a cavity without the requirement of a core.

mould accessories

Get Price Quote

We supply standard Mould Accessories like Ejector Pins, Punches, Sleeves, Die Spring, Mould Clamps etc. of various shapes and sizes. We also supply Hot Runner Systems and controllers for critical plastic item moulds. Water Manifolds of different combinations can be supplied to suite Mould requirements.

Moulded Rubber Components

10 - 500 Per Piece

1 Piece (MOQ)

Mastic Positioner

10 - 20 Per Piece

1000 Piece(s) (MOQ)

We are the main supplier of this product.

Rubber Moulded Components

Get Price Quote

Manufacturing Of Moulded Rubber Parts. Established in 1991 we are in the field of manufacturing and exporting rubber components, molded rubber products, rubber sheets, inflatable rubber seals, endless rubber gaskets,rubber bellows.

Plastic Moulded Components

Get Price Quote

We provide Plastic Moulded Components which are known for their sturdy make & work accuracy. We frequently keep a check on the storage space to ensure that it is well-maintained by the experts. We have installed the latest machines and leading technologies to save products from spoiling. Stay rest assured for the products that we offer as they will remain damage free. For this, we make use of only premium packaging material for the packing of the products.

Plastic Molding Components

24 Per Piece

2000 Piece(s) (MOQ)

Plastic Molding Components

Get Price Quote

Plastic Molding Components is one of our profession handled by experienced & qualified contract manufacturers. We caters small quantity requirements which are not easy to manufactured by the big business houses & makes it convenient for our customer to order it without investing more on inventory. We are growing steadily in the arena of manufacturing and export of irrigation drippers, plastic caps, automobile plastic parts, section parts etc. The products manufactured by us are highly admired by our customers for their acme quality. The well laid infrastructure of the factory set up & with staff of well experienced and skilled technician helps us to provide complete plastic solution incorporating principles of : Product Design Mould Design Mould Procurement Optimum Material Selection Product Testing and Supply Our high quality components satisfy our clients needs of following categories : Textile machinery parts Plastic gears Plastic caps Plastic knobs Section parts Automobile plastic parts Electronic components

SRBF Moulded Articles

Get Price Quote

electrical moulded component

Get Price Quote

We, at Raj Engineering are actively involved in the production and distribution of Electrical Moulded Component. The Electrical Moulded Component, provided by us, has huge market demand, due to the quality make and excellent features. We provide the Electrical Moulded Component to the clients in assorted grades & specifications to cater to the diverse needs of the clients.

Moulded Rubber Components

Get Price Quote

Get in touch with us, if you are looking for Moulded Rubber Components. We hold specialization in manufacturing, exporting and supplying of Moulded Rubber Components. These components have found wide applications in various industries. They are dimensionally accurate, ductile in nature and have excellent tensile strength. We can also develop the Moulded Rubber Components as per the specifications mentioned by buyers. We can process bulk orders.

injection mould base

Get Price Quote

Injection Mould base - We are one of the well known Manufacturer & Supplier of Injection Mould base. We are specialized in Injection Mould base. These Injection mould base is used for assisting plastic and molding such as household mould, communication mould and kinds of mould.Injection molding is a manufacturing process for producing parts by injecting material into a mold. Injection molding can be performed with a host of materials, including metals, glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers. Parts to be injection molded must be very carefully designed to facilitate the molding process.Injection molding utilizes a ram or screw-type plunger to force molten plastic material into a mold cavity; this solidifies into a shape that has conformed to the contour of the mold.Injection molding consists of high pressure injection of the raw material into a mold which shapes the polymer into the desired shapeInjection molding machines consist of a material hopper, an injection ram or screw-type plunger, and a heating unit. They are also known as presses, they hold the molds in which the components are shaped.We are specialized in manufacturing Plastic Injection Standard Mold Base and Customized Mold Base as per customer's requirement. 1. 2 Plate Mold Base for Plastic Injection Mold 2. 3 Plate Mold Base for Plastic Injection Mold 3. Side Gate Mold Base for Plastic Injection Mold 4. Pin Point Mold Base for Plastic Injection Mold 5. Hot Runner Mold Base For Plastic Injection Mold Material used:- Mild steel, C-45, P-20, 1.2316 & all type of alloy steel All Mold Base are produced on high precession imported CNC (Vertical Machining Centre), imported Conventional Machine and are inspected before dispatch, we produced Mold from 200MM X 200MM onwards. Our Standard Mold Base assists the Tool Room manufacturing and plastic industry such as Household, Cap Enclosure (Multi Cavity Mold), Electrical, Engineering etc. Our company porduce Injection Mould base Injection Mould base advantage Faster Delivery (Saves time) Can concentrate more on core activity like design, Core & Cavity. High production rates, Standard part easily available for replacement. Low labor cost Large volume production possible Easily automated Minimal scrap loss Minimum secondary operations Permits very small parts Tight tolerances can be maintained Complex part capability

DMC Moulded Components

Get Price Quote

We are listed at the apex in the list of the eminent DMC Components Exporters from India. Customers from all round the globe are placing repeated orders for the DMC Moulded Components as no alternative is available in terms of quality and performance. The use of optimum quality materials in the manufacturing of the DMC Moulded Components ensures high durability, tensile strength and resistivity to adverse conditions. Additionally, customers are eased with the availability of the customized Industrial DMC Moulded Components as per the specifications and drawings provided.

sleeve ejector

1 Per Piece

600 Piece(s) (MOQ)

mold parting lock

70 Per Piece

Moulded Rubber Components

Get Price Quote

Duflon manufacturers rubber moulded or extruded components for a variety of industries. These are all bespoke components and Duflon is geared up to supplying from very small quantities up to quantities in millions.The secret to manufacturing a good rubber component is in the tooling, and Duflon has a team of specialist elastomer engineers who have vast experience in tool making. Rubber compounding facilities are available for manufacturing compounds to meet specific applications and conditions. Whether you have a fast turnaround pilot requirement or mass production, Duflon is able to cater all scenarios

custom made mould base

Get Price Quote

Tailor made mold base as per customer's requirement

Moulded Rubber Components

Get Price Quote

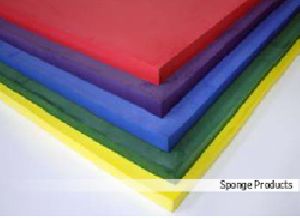

We offer a wide range of molding products that are tested on differentparameters before dispatching. We customize these products as per therequirement of our clients and offer them at affordable prices. To ensuretheir quality, we manufacture them as per the ISO standards of industry.With the help of our dexterous team, we manufacture superior customrubber products. These rubber products are manufactured as per the technical specifications and drawings provided by clients. Theseproducts are available in continuous length or pre-joints in D-shape, Lshape,U-shape, square & rectangular shape.Product Range:• O Rings• U Rings• V Rings• Oil Seals• Gaskets Rubber bellows, heat exchanger gaskets, synthetic rubber bellows,synthetic bellows for a broad range of industries, including medical,aerospace, commercial, industrial, government/military, hightechnology,office automation and transportation as well.Molding is a preferred method where tolerances and consistency arecritical. Although an initial part tool cost is taken for the mould, themoulded items are cheaper to produce.Molded products are supplied in avariety of polymers such as Silicone,white EPDM, white food qualitynatural, chloroprene,etc. Available in multiple colours, these productsare a favorite to our customers. Sponge ProductsOpen cell and closed cell from a variety of material such as EPDM,neoprene, PVC nitrile, silicone, as well as polyethylene and many more.Many types of foam can be produced with a self-adhesive backing. Wealso supply furniture foam, which has many more applications than justfurniture. These are supplied in sheet, strip or any cut profile shapedform as well.

Compression Moulding Components

Get Price Quote

SINTERED POROUS PLASTIC MOULDED COMPONENTS

Get Price Quote

Expertise and specialties in chemical, mechanical, industrial, biological and research engineering which has led to the development and refinement of production techniques enabling us to economically supply simple or complex custom made shapes in a range of sizes, porosities, with colours impregnated Activated Charcoal of Iodized and silver as well have the expertise to work with you to ensure the right match between our capabilities and your requirements.

Compression Moulding Components

Get Price Quote