Transition Coupler

Transition coupler are designed to splice different diameter bars where at least one bar could be rotated. The tensile strength of the joints matches requirement for tensile failure of smaller diamater bar. Torque value to ensure correct assembly of coupler ioint Touaue/Bar Dia 16mm 20mm 25mm 28mm 32mm onward Coupler (Nm) Lock nut (Nm) 120 30 160 50 250 80 275 90 300 100 Pipe wrench/torque wrench to ensure correct assembly of coupler and bar

...more

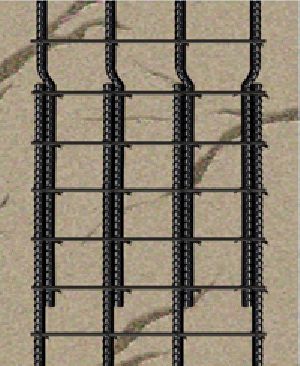

Standard Taper Threaded Coupler Coupler

Mumbai Rebar Solutions Standard Coupler are designed to splice the reinforcement bars where at least one of the bars could be rotated. The taper threaded design of coupler helps easy engagement of the bar within the coupler with simple alignment. The standard taper threaded coupler comprises of internally threaded sleeve with two right handed threads tapering mid length of coupler.The bar ends to be spliced are saw cut and taper threading is provided on bar ends with proprietary branded threading equipment and thread cutting devices. The bars are connected initially by hand tightening and then with pipe wrench (torque wrench may be preferred) The Splicing system provides butt joint when the bar threading is fully engaged with coupler by appropriate tightening. The Mumbai Rebar Solutions splicing complies with BS-8110 Part 1, 1989 & BS-5400 Part 4, 1990 andACI-318. The couplers are supplied with internal thread protection plastic cap, The compact design of coupler ensures that no extra concrete cover is demanded for coupler protection.

...more

REINFORCEMENT BAR COUPLERS

Reinforcement Bar Splicing The traditional method of connecting reinforcement bars with lap joints continuity in reinforced concrete need not be always appropriate. Advantages of simplicity and economy in lap splicing is limited to smaller diameter bars, Mumbai Rebar Solutions mechanical couplers offer the solution for splicing when large diameter bars are involved. Conventional Lap Splicing Mumbai Rebar Solutions Mechanical Splicing: A union reliability Technically Superior: Spliced rebar performs like continuous reinforcement. Splicing develops strength mechanically, independent of concrete. Therefore provides ductility in RCC structures independent of condition of concrete. Proven cyclic performance of spliced rebar offers strength during man-made, seismic or other natural events. The continuity of spliced rebar offers excellent provision for grounding electrical current. Designer friendly: Mumbai Rebar Solutions coupler reduces rebar congestion and improves concrete flow & consolidation. It offers greater flexibility in design options. The simplicity in detailing of reinforcement, particularly in reinforcement congestion zones minimizes the reinforcement fixing errors, detailing and fixing of seismic reinforcement becomes effortless. Workability with higher steel-to-concrete ratio allows optimum sizing of RCC structural members. Contractor's preference: Mumbai Rebar Solutions coupler offers quality, cost and time saving. Fixing couplers requires no special skills or equipments. Simple mechanical ways in adopting mechanical splicing compared to lapping, accelerates construction schedules for optimum cost and efficiency.Handling the rebar in convenient sizes saves on valuable crane time. It is economical to use couplers for higher diameter rebar as it saves on considerable weight and rebar wastage. Special application for micro-piling, piling, slope protection, pre-cast concrete, slip-forming, formwork protection, top-down construction makes Mumbai Rebar Solutions coupler as a part of any major project.

...more

Parallel Threading

Advantages of Parallel Threading System Continuity of Re-enforcing bars Allows full ductile elongation of bars No Congestion of bars Construction cycle time reduced Steel wastage reduced Staggering of bars not required Dowels can be avoided enabling re-use of form works Our Mumbai Rebar Solutions is a threaded connection which guarantees an ultimate tensile strength of the joint (Splice) slightly greater than that of the parent bar. Each of the connection constitutes, one sleeve that connects two bars, the ends of these which are threaded using our machines. Applications/Usages of Parallel threading : Mumbai Rebar Solutions splicing system is very much suitable to join reinforcement bars end to end. Mechanical connections are quicker, safer and also more convenient alternative to lapping. It is applicable in splicing of reinforcement bars, columns, beams, diaphragm wall cages, construction joints, temporary openings and Top down constructions etc.. Quality:Every thread produced at site will be checked with Go - NO GO gauge to ensure the quality of threading. FEATURES ACI 318-95 Clause 12.14.3.4 A full mechanical connection shall develop in tension or compression, as required, at least 125 % of specified yield strength of the steel bar. BS 8110 pt: 1997 Clause 3.12.8.16.2 The only form of full strength butt joint for a bar in tension comprises a mechanical coupler satisfying the following criteria. When a test is made of a representative gauge length assembly comprising reinforcement of the size, grade and profile to be used, and the coupler of a precise type to be used, the permanent Elongation after loading to 0.6 fy should not exceed 0.1 mm. The tensile strength of the coupled bar should beFor Grade 250 >= (287.5)N/mm2For Grade 460A >= (483)N/mm2, andFor Grade 460 >= (497)N/mm2 Full Tension splice. Bar break under tensile load. No Torque wrenching required, Easy to install. Bar Cross section area is not reduced. Manufactured under strict quality assurance. umbai Rebar Solutions MECHANICAL SPLICING SYSTEM: Increase tensile and compressive capacity of columns, long columns and long beams where the designed tensile loading are greater than normal situations. Tension couplers is so far the best solution for tension columns and tension piles. Eliminates congestion of steel bars in heavily reinforced columns and core wall of building. Thus reducing formation of "honeycomb" in concrete structures. Speedier concrete casting,as bigger space between reinforcements facilitates easier flow of concrete. Reduces cost and increases speed of slip and jump form work system in the construction of core walls and towers. Avoids strains, corrosion and breakage of starter bars left for future extension of building and bridges. For construction of structure like bridges in traffic congested area where structure could be constructed in stages to allow constant flow of traffic. Provide connections for starter bars for underground slab and beams in the construction of diaphragm wall to prevent breakage of precast starter bars during the process of bending up to avoid tedious concrete hacking. Where spacing between bars is insufficient to allow for lapping, e.g. in construction of mircopiles. Reduces size of concrete section and ensures maximum usage of expensive floor space in office towers. Where a full tension splice is required, e.g. in connecting precast members to cast-in-site members.

...moreBe first to Rate

Rate ThisOpening Hours