Zero Hold-Up Type

Technical Specifications :Model - 8", 14", 18", & 33" Dia. of plates.Reverse Flow design for practically zero hold-up.Offered on common skid with filter aid dosing system. Cold pressed & spinned filter plates for long life.Tee design Tie Rods for ease of operation.Shell thk. is suitable to withstand higher pressure.Diaphragm type SS 316 pressure guageIn built re-circulation arrangement.MSSS jackets for high temperature applications.Suitable pump can be intregal part of the assembly. Duplex systems offered for continue process appli.Features of Reverse Flow Model :Zero Hold-up of Filtrate without scavenging operation. Superior clean filter tank processing.Fast & easy removal of filter plate cartridge due totop dome construction. Hence, easy removal of cake.

...more

Wet Tissue

Vibro Sifter

Special Features :Model available 12", 20" & 30" dia. cap. Available in Single/Double/three deck.

...more

Tube Filling Machine

Fully Auto. Tube Filling/Sealing/Trimming & Coding Machine (For Plastic & Aluminium Tube)Consists of:One rotating disc with interchangeable tube holding sockets for different sizes of tubesSS Filling Syringe Pumps with Teflon ringsSS Filling Nozzles connected to control of "Tailing" with pneumatic systemNo-Tube, No-Fill Sensor, Diving Filling SystemHot air heating of tubes, pneumatic sealing & batch coding and trimmingOne 20 litres capacity SS hopper for paste / ointment One SS block with non-return valve, volume track with fine adjustment and accuracy of +/ - 0.1 %Filling range : From 3 gms to 100 gms with interchangeable syringe pumps for each colour paste.Filling speed : 35, 40 & 45 tubes per minute for manual feedingOptions Available: Mechanical auto feeding of tubes Speed: 45, 50 & 55 tubes/minute.Triple Colour Filling Machine also available.

...more

Tray Dryer

Features :Covered drivesTwo tier trolly with S. S. rollersSuperior controls Improved design- double door provisionEnhanced performance by total insulationInlet air - Hepa filteredGMP features:Rounded corners and anglesEasy accessibility of Impellers for Hygienic cleaning.Even thermal distribution internally all over the chamber.Capacity offered:1.6 Trays. : Single Door2. 12Trays. : Single Door3.24Trays. : Single/Double Door 4.48Trays. : Single/Double Door 5.96Trays. : Single/Double Door

...more

Storage Tank

Salient Features :Capacity in Ltrs.: 100, 200, 500, 1000, 2000 & above.Storage tank provided with drain cock, top cover & castor wheel mounted legs.Inside & outside surfaces are polished to the mirror finish.Storage tank made from SS316 Quality with lid ,leg ,wheel ,ball valve.Tank should be mirror buff with smooth finish.

...more

Sabudana

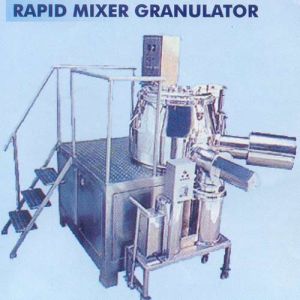

Rapid Mixer Granulator

Salient Features :Model available from 25 ltrs. to 1000 ltrs. capacity.Can be used in the fields of Pharmaceuticals I Bulk Drugs and processing of special food stuffs.Short batch time & reduced cleaning time.The seal housing and drive may be flushed with cleaning water, which is then drain away from themachine through built in drain tubes.Enclosed moving parts. Maximum care has been taken to ensure machine safety.Air purge sealing for main shaft & granulator shaft.Auto I Manual Controls.System control ranges from simple manual push button control to full programmable logic controller (PLC) based automation.GMP I Flame-proof I SS316 construction on demand. Discharge provided on either side to suit Client's requirement. Steam Jacketted drying also available on request to meet specific process requirements.Jacketed vessel for heating or cooling.Binder solution adding & cleaning in place (CIP) in built. Variable speed drive for main and chopper impeller.Impeller lifting device & Powered main lid opening.

...more

Powder Mass Mixer

Salient Features :Well-designed to facilitate through mixing & Ease in cleaning.Safety Plastic Dust cover provided with inter locking system, safety device in a way stick that on opening of the cover the machine stop functioning. Tilting device Is provided for ease in unloading by means of Handle wheel.Specially designed self-adjusting sealing arrangement to ensure no black particles enter into the mixing drum.

...more

plantary mixer

The Planetary motion of the mixing beater ensures effective homogenous mixing of the various ingredients. Std. Mixer consists of single mixing. beater which rotates in planetary motion i.e. clock wise direction about the central axis, anticlock wise direction about its own axis. The main drive, lifting and lowering operations is motorised. The product bowl is mounted on caster wheel for easy portability' for washing and transporting the materral.Vacuum Jacketed Mixer consists of 2 open beaters moving in planetary motion, scraper blade ¢rally located high shear emulsifier run by separate motor for mfr. of creams, ointments, suspensions etc.

...more

Planetary Mixer (Powder)

Salient Features :Models -100, 200, 360, 500 ltrsOccupied smaller floor space for installation.Castor wheel mounted product container for ease of mobility. Planetary motion of the beater enables faster & better nixing of material at considerably lesser time.Manual lifting arrangement for mixer up to 100 Ltrs. Capacity & motorized Hydraulic lifting arrangement for 200 Ltrs. & above capacity models.Water jacketed product container having dished end type bottom & electrical heaters to heat or cool the product during mixing, for Ointment, Cream, Paste, Lotion mixing.

...more

Oscillating Granulator

Salient Features : Oscillating Granulator, plays an important part in the process of granulation in tablet making as quality of tablet is determined by the virtue of the granules used for its compression.Oscillating granulator can be used for wet and dry aspect of the granulation process.Quality of granules are better compared to other processing machineries like multi mill, comminuting mill etc.Adjustment, cleaning and operation are simple Sturdy, durable, better productivity.Unique oscillatory rotor action ensures high outputs and a predictable product with minimum of fines.

...more

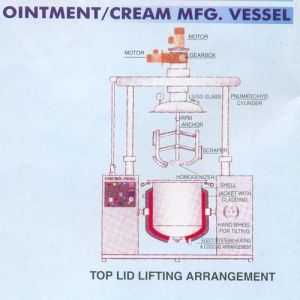

Ointment-Cream Vessel

Salient Features: Capacity: 5 kg to 500 kg.Suitable for lab as well small batch.Top mounted homogeniser.Lid liftingtilting arrangement provided.Dual speed for anchor & single speed for homogeniser. Vaccum arrangement can provided.MOC SS 316316 L.cGMP with documentation.

...more

Octagonal Blender

Salient Features: Contact parts in stainless steel 304 or 316.Baffles provided for ease of mixing / blending.Manhole with gasket is provided to fix baffles and for ease of cleaning the Main pan.Charging and discharging is through a butterfly valve. A conical adaptor can be provided for fixing charging drum after butterfly valveUnit can be provided with bin charging arrangementAll moving parts are enclosed in guardsA safety railing with a limit switch is provided for operator safetyManual Inching arrangement can be providedFlame - proof motors with flame - proof push button stations can be provided as an optional.

...more

Multi Mill

Salient Features :All contact parts can be easily & quickly dismantled & cleaned.Machine is designed for continuous operation.Cylindrical screen for higher output.Castors provided for mobility.Beaters and scraper blades of 88410 Q are hardened and hard chrome plated.Direction of beaters can be changed by reversible switch.Technical Specifications :Rotor assembly dia = 250 mm (approx.).Rotor speed = 750/1500/2300/3000 RPM. Material charging ht. = 1445 mm (approx.) Material discharging ht. = 730 mm (approx.) Beaters = 12 nos. knife & impact edges, 2 scraper blades.Output = 50 to 200 kgs./hour depending upon the product & the reduction required in size.Overall dimensions = 870 x 965 x 1630 mm ht.Net/Gross Weight = 280/430 kgs. (approx)

...more

Fluid Bed Dryer

Salient Features :Design confirming to GMP norms.Model available ranging from 5 kgs. To 300 kgs.Bucket type bottom chamber above ground level.Intrinsically safe earthing arrangement.Air filteration supplied with 20 micron washable filter followed by 5 micron Microvee filter & finally air is passes through 0.3 micron Hepa Filter (Optional)Differential pressure gauges to monitor pressure drop across inlet filters and air filters.Clean in Place systems for washing down during product changes.On line sampling facility.Pneumatically Operated system for lifting & sealing of Product Container.Product container lifting platform and air cylinder replaced by pneumatically operated gasket. (Optional)Inflatable gasket system for sealing lifting platform with bottom jack chamber instead of bottom bag. (optional)PP Finger bag fitted with the help of inflatable silicon rubber tube. Automatic pneumatically operated shaking system with timer & butterfly valve.Fully sealed air control damper with positional for accurate air monitoring.Solid flow chart monitor for detection of torn finger bag also available, which automatically STOP the machine blower if it detects any particle escaping from torn finger bag towards exhaust.Rear chamber with heating coils and air inlet filter modules to be mounted in remote areasFan motor unit to be mounted in remote areas.Stainless steel interconnecting duct lines with flanges for connecting remote mounted heating and fan motor modules.Noise level below 90 DB with specially designed silencer Micro-processor based control panels with key board, display unit & printer.

...more

Dry Heat Sterilizer

Features :Micro Processor for Process Operations with 10 ProgrammeHepa Filtered Air Module in Inlet. S.S. Construction8 Chanel Temperaturescanning with Processormimic Display On Control PanelDoor Inter Lockinghelps for Fault FindingCooling Attachment for Rapid Cooling.Heaters Accessed from Non-sterile Side. Complete GMP Model

...more

double cone rotary vacuum dryer

double cone rotary vaccum dryer

Most suitable for drying of materials which can not resist high temperature, material which are easily oxidised, volatile materials which should be retrieved, materials strong irritant and poisonous in nature. The rotocone dryer with improved technology integrates during operation under vacuum. The rotocone dryer facilitates enhanced drying efficiency, low temperature operation and economy of process by total solvent recovery.Advantages :Reduces drying time Uniform material shuffling over the heated contact surface of the cone. Handling and exposure of final product is avoided. Eliminates need for redrying of lumps. System can process crystalline or amorphous powders which are prone for lumps Optimum and continuous vacuum during process.Salient Features :Totally sealed & protected from contamination.Provision of sampling nozzle without breaking vacuum.Cyclone separator provided for recovery of any solid particle escape.Suitable size condenser & receiver provided for solvent.Mechanical seals for vacuum & hot water connection.Variable speed drive is provided for fine adjustment of the speed.

...more

Double Cone Blender

Salient Features: Model: 25-3000 Litrs Capacityone end of the Blender has a Hinged Cover for Quick Opening & Charging is done at inclination & an Iris Diaphragm / Butterfly Valve is used for discharge.mfd. in 88304/316, the Design is aesthetically suited to the Modern Pharmaceutical Plant.the high quality of design ensures that the Operator Panel is easy to use & cleaning of equip. is simple.loading the Blender by Vacuum.for higher capacities of Blender, the loading can be done by an I P C. 11111

...more

Distillation Plant

Scope of Supply :Multi-Stage/reciprocating Feed Pump Made Out of SS 316. Stainless Steel Centrifugal Pump for Cooling Water.SS 316 surge tank with float valve and low level controller. SS filter with SS housing for feed water.Pressure reducing Valve & Safety Valve for higher capacity. S.S. 316 Dumping Valve.Capacity from 80 litres to 3000 litres.Salient Features :Pure sterile, pyrogen-free distilled water.Compact space saving design.High operational reliability.Meets GMP & FDA norms.Easy & silent operation.Excellent energy efficient.Easy to maintain & operate.Fully automatic operation.Absence of rotating parts.Rapid warm up.High degree of finish.Auto dumping of sub-sdandard distillate. Special Sanitary Fittings.Technical Specifications:Distillate : Meets I.P./B.P. specifications.Temperature : 950C.Conductivity : Less than 1 Microsiemen/cm.Feed Water : De-ionised water with maximum conductivity of 5 Microsiemens/cm. : 1 Kg/cm2 higher than the in-feed steam pressure. Temperature: ambient.Cooling Water : Normal tap waterHardness : less than 90 PPM of CaC03.Temperature. : ambient.Steam : Saturated, dry, free from oil & other impurities.Pressure : minimum 3 Kg/cm2.Electricals : Main supply: A.C. 440V, 3 phase, 50 cycles. max. load-5 KW.

...more

Conta Blender

Method of Operation :Container has four castors at the bottom on which one can roll it comfortably under the cage blender frame. For heavy containers, one can use fork lift pallet truck to transfer the containers. After bringing it under the frame, operate the hydraulic drive system which lifts the bottom platform and this bottom platform lifts the container along with its castor wheel and it raises the container till it gets locked with the top frame " positively. This activates a sensor which than allows the blender to start.After blending time is over, the container stops exactly in a position where container is vertical position and then it could be lowered on it's four wheels.Salient Features :Container is skewed by 30° in the horizontal plane before it is being raised for blending. Horizontal skew axis is 10°. This dual blending axis results in gyratory motion for proper blending.Use of square or rectangular container ensures material going from one side to another as it is rotated ensuring perfect blending.Bins designed as per EURO standards and are made as per latest cGMP standards.In-built lifting arrangement for containers.Capacity available 100 l to 1000 l

...more

Colloid Mill

Salient Features :All contact parts are made out of SS 304 / SS 316 quality material.Coupling provided between motor shaft and rotor for the ease in maintenance. Special sealing arrangement between the motor & the processing chamber to prevent liquid going in side the motor winding, resulting in burning of the motor.Modified design of semi concave teeth in rotor & stator gives better performance in size reduction without damaging the product.3 way cock system for draining & re-circulating of liquids & discharge spout for viscous products provided as a standard.DOL Starter with overload relay for protection against 1-phasing & low voltage. Contact parts can be easily dismantled for cleaning.Flame proof / SS316 /GMP construction on demand.Technical Specifications : Motor : 3 HP / 2800 RPM / 3 PhStarter : D.O.L.Hopper Cap. : 15 Ltrs.Output : 15 to 1500 Ltrs/Hr.(depending upon the size of particles required) Particle size reduction up to 5 microns.

...more

Coating Pan

Models:- 12, 24, 36, 42, 48, 60, 72 inch Dia. The gear box, motor & hot air blower are enclosed in a SS, in case of GMP models.Mounted on dynamounts to avoid foundations. Heaters interlocked with the blower fan. Spray system with pressure tank and spray gun. (Mini Cota). Peristaltic pump for metered dozing. Exhaust blower as optional.

...moreBe first to Rate

Rate This