Thermosetting Injection Molding Machine

Special treated barrel and heater made of aluminum alloy to ensure barrel temperature consistency. Platen is enclosed with heat insulation board made of asbestos helps to increase production efficiency. Suitable for bakelite, phenolic, urea and etc.

...more

Pet Preform Injection Molding Machine

Specialize in PET material. Supply complete system integration including PET preform injection machine, PET preform mold with hot runner and temperature control, ancillary equipments from material drying and feeding to preform cooling and automation.

...more

Hydraulic clamping Injection Molding Machine

Central direct clamping mechanism combined with two injection cylinders system generates accurate clamping pressure and quick mold close. Long mold opening stroke and less restriction on mould thickness make it flexible for mold application. Clamping force distributes evenly to the mould and the platen, minimizes stress and wear on machine.

...more

General Purpose Injection Molding Machine

Five-point vertical toggle system combined with one piece fabricated machine bed, ensures machine strength and durability even under high speed production. High rigid T-slot platen made of FCD500, eases process of mold mounting and withstand fatigue of platen. Oil less bearing improves machine cleanliness with less use of lubricant. Two cylinders design makes injection move faster with ease.

...more

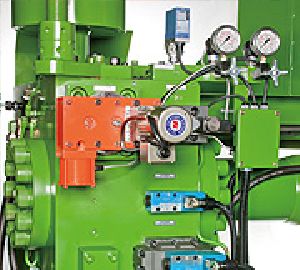

Die Casting Machine

The V3C models are the most mature machines with the widest application range. They are also the most reliable and automated machines. Features: One piece design for the injection system The most efficient oil circuit with excellent injection performance. Integrated structural rigidity with self-lubrication design for long service time. Easy to install peripheral equipment for automation, which increases efficiency and saves man power. User-friendly Man-Machine Interface (MMI) with alarm device. Multi-stop injection adjustment provides a reduction of swelling gas in the barrel, while upgrading die casting product quality. There are three injection models including soft start with constant speed injection, constant acceleration injection and multi-stage injection for flexible production. The use of a P/F valve helps to increase convenience of operation while reducing electricity consumption up to over 15%. Available to be equipped with a servo controlled energy-saving electrical system for saving electricity consumption up to 50%. The Full Test function provides a simulation of die casting process that allows the operator to realize the aluminum liquid flow condition during a molding cycle.

...more

Accumulative high-speed Injection Molding Machine

Specialize in production of thin-wall items and high-speed injection. Close-loop injection equipped with high feedback proportional and directional valve to assure injection consistence. Double loops system (injection pressure charge during holding pressure/material charging) available as option to improve cycle time.

...more

Injection Molding Machine Repairing Services

Be first to Rate

Rate This