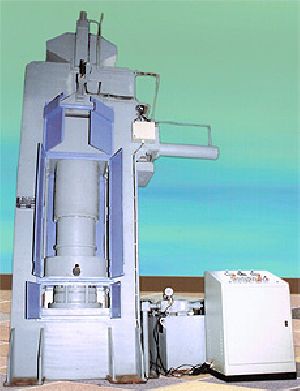

Mark 30 Oil Expeller

Get Price Quote

1 Piece (MOQ)

TRIMURTI OIL MACHINERY is being used satisfactorily in India and many overseas countries for over 40 years. Our models incorporate the latest international design specifications and technological developments. The enhanced efficiency thus obtained gives you savings in terms of time, money, and labor. TRIMURTIMARK 20 OIL EXPELLER and TRIMURTIMARK 30 OIL EXPELLER, our 2 recent models, meet the demand of high capacity high yield expellers. Our designers have spared no effort to make these models strong and sturdy. TRIMURTIOIL MACHINERY is easy to install and gives you long trouble-free service. 20, MARK 30 OIL EXPELLERS Crushes in a single pressing operation approximately 20 tons to 30 tons oil seeds in 24 hours and leaves behind 5% to 6% oil in the cake. CHAMBER BOX Being vertically hinged it opens like a book and saves the trouble of removing it from expeller during a change of worms. This is a great time and labor-saving improvement. COOLING OF CHAMBER Oil from the oil settling tank is pumped and sprayed by a special motorized pump which is part of the standard equipment. Oil thus flushed on the chamber removes the feet and also cools the chambers. As a consequence, the life of the spare parts is enhanced. GEARBOX The gearbox is robust and of close-grained C.I. Casting fitted with heavy bearings and tempered helical steel gears that run in an oil bath. These hobbing cut teeth gears run silently and have a long life. BODY AND CENTER BODIES These are fabricated from tested steel plates. PRELIMINARY COMPRESSION The cooked meal from the kettle is compressed and consolidated by a packing worm before entering the chamber box, where oil extraction starts immediately. The packing worm is driven by an automatic tension belt which stops whenever the feed is excessive and starts again as the accumulated material has been taken over the feed worm. MAIN WORM SHAFT WITH WATER COOLING ARRANGEMENT The worm shaft is of special alloy steel of high tensile strength to withstanding shock and strain. It is stepped in design to assist the easy withdrawal of worms and collars. The shaft can be removed without disturbing the main thrust bearing and main gears. It is equipped with the necessary motorized pump for water cooling arrangement. COOKING KETTLE MARK – 30 The expeller is fitted with a FIVE stage cooking kettle. It is compact in design and is fitted with a self-controlled meal inlet to prevent overfeeding. It also fitted with a safety valve, a pressure gauge, steam traps, a steam valve, and a steam damping apparatus. It is independently driven by a 20 HP motor through a reduction gearbox. FLOW OF OIL AND FOOTS FROM EXPELLER A conveyor is provided in the oil tray of the expeller which conveys oil and feet to oil storage tanks. POWER The power required depends upon the material being crushed and how well it has been cooked. The normal requirement for usual seeds is MARK – 20 75HP 1000 RPM MARK – 30 125HP 1000 RPM CAKE The thickness of the cake at the discharge is controlled by an automatic mechanism that can be operated to increase or decrease the cake thickness even while the expeller is in motion. DURABILITY All those parts of which are subject to heavy wear and tear such as worms, cage bars, cone points, etc. made from special alloy steel, are properly hardened and tempered (heat-treated) to give them a long life and a low maintenance cost. Note: We reserve the right to make alterations to the machine from time to time as required.

Oil Expeller Machine

23,000 Per Piece

1 Piece (MOQ)

Best Deals from Oil Expellers

Oil Expeller Machine

Get Price Quote

Mustard Oil Expeller Machine

Get Price Quote

We have separated our infrastructural facility into several units and one of them in warehouse. In order to maintain high quality standards, we laced our facility with modern technology. Designed and developed using the premium raw material and modern work methods; we guarantee high quality standards and longevity of our products. Also, we make sure that the raw material is sourced from the trusted places.

Oil Expeller 3/4 TPD

Get Price Quote

We are offering oil expeller. Kumar mk I oil expeller capacity 3 tonday. Hp required – 10 hp kumar new oil_n_oil series single chamber oil expellers are designed for greater flexibility, capacity and efficiency. The expeller is supplied with triple reduction helical gear box coupled independently with expeller’s main motor. the gear box is state of the art technology and energy efficient. It is made as per european standard and is ce certified. the expellers are supplied with 2 to 6 stage stack cooker for conditioning the oil seeds before crushing. These cookers are self driven with their independent geared motor. Kumar new oil_n_oil series expellers are designed for crushing all types of oil seeds like sunflower, mustard, groundnut, sesame, soybean, copra, palm kernel, jatropha, shea nut and various other edible and non edible oil seeds. Kumar expellers are being manufactured since 1939’s and are upgraded with the modern technology. Salient features : • maximum oil yield at low operating cost. • easy and time saving main worm shaft removal. • special designed locking type clamping bars and bolts. • worms and collars are hardened and tempered • cage bars are hardened and tempered • heavy duty bearings for thrust loads. • low residual oil content in cake. • low power consumption.

Oil Press Machine

16,500 Per Piece

1 Piece (MOQ)

Sunflower Oil Press Machine

500,000 Per Piece

Oil Filter Press

Get Price Quote

Are you looking for Zero Hold Up Filter Press Machine? You are at the right place. We – Pratik Enterprises are leading manufacturers and suppliers of Zero Hold Up Filter Press Machine in India. With years of experience, expertise and knowledge, we have built broad client base across the world. This machine is manufactured by us with very high quality material and as per the international industry standards to meet the changing needs. Zero Hold Up Filter Press machine manufactured by us has been tested at various levels and it requires very low maintenance. As we have customized this machine as per client’s requirements, in compliance with various industrial standards it is user friendly – very easy to operate and compact in design. Before the final dispatch, the entire range is stringently checked by our expert quality controllers for flawlessness, quality and durability. Read below the technical specification and features of our most popular machine – Zero Hold Up Filter Press Machine

integration oil press

Get Price Quote

We are counted amidst the most dependable Integrated Oil Press Importers in India. Various national as well as international clients are showing their interest for the Automatic Temperature Controlled Integrated Oil Press due to the inexplicable performance exhibited in respective applications. The Automatic Integrated Oil Seed Processing Machine combines normal traditional 3 stage operations in Oil Extraction System into a single processing unit. The Oil Seeds are fed in the hopper at the top and filtered oil is collected in the Tanks at the Bottom. The operation of this machine is totally trouble free, clean, neat and non-messy. The Repair & Maintenance is also very simple. There are different models available ranging from capacity to process approx 1 Ton of Oil Seeds / day to 6 Tons of Oil Seeds / day. Automatic Temperature Control Integration Oil Press This Integrated Oil Seed Processing Machine does following 3 Operation in single process totally automatically Oil Seed Heating with the help Electrical Heating System. Immediately Squeezing the heated seeds to extract oil with highest yield % continuously and Vacuum Filtering the extracted raw oil and collecting clean filtering edible quality oil in the twin SS Tanks which can be pumped into the overhead tank for packing. In contrast to the old traditional system which generally needs following equipment Water Heater (Boiler) Feed Water Pump Steam Kettle Oil Expeller Filter Press and Pump for feeding fitter press. The Integrated Oil Seed Processing Machine is a single machine incorporating Continuous Electric Heating Zone which provides uniformly Controlled Temperature. Oil Press or Expeller attached to the Heating Zone and Oil collection Tanks bellow the expeller attached to the Vacuum Pump. The Oil Seeds are fed in the hopper at the top and filtered oil is collected in the Tanks at the Bottom. The operation of this machine is totally trouble free, clean, neat and non-messy. The Repair & Maintenance is also very simple. There are several models available ranging from capacity to process approx 1 Ton of Oil Seeds / day to 6 Tons of Oil Seeds / day. A brief Technical Details are as under:

Oil Press Machine

Get Price Quote

We are offering oil press machine. we have in store a distinctive 3 in 1 completely integrated oil press machine. Our oil press machine efficiently makes a combination of 3 stage operations in oil extraction system to a single processing unit. Apart from this, our automatic temperature control integration oil press machine has facility to separate the oil seeds in the hopper on the top and filtered oil in tanks present at their bottom. The models of oil press machine available with us range from the capacity that can process approx. 1 ton of oil seeds to 6 tons of oil seeds per day. the three operations in single process electrical heating system ensures perfect oil seed heatingthe heated seeds can then be quickly squeezed for continuously extracting oil with maximum yield percentagethereafter, it is essential to vacuum filter the extracted raw oil and collect the filter cleaned edible quality oil inside the twin ss tanks that allow the packing by pumping into the overhead tank product equipment water heater (boiler)feed water pumpsteam kettleoil expellerfilter presspump for feeding fitter press machine consists of to get uniform controlled temperature, there is a continuous electric heating zonethis heating zone comprises oil press or expeller attached to itbesides, the oil collection tanks that are present below the expeller are attached to the vacuum pump features cleannon-messyneattrouble freeeasy to repair and maintain

oil expeller, 15 bolt ,2 machine

Get Price Quote

oil expeller, 15 bolt, 2 machine, 2 filter, Ss 304 tanks for storage

oil mill filter presses

Get Price Quote

oil mill filter presses, extraction plants, root trainers, Propagation Trays

Castor Oil Press

Get Price Quote

Castor Oil Press, Dish Making Hydraulic Press, Die Cushion Hydraulic Press

mustard oil expeller

Get Price Quote

mustard oil expeller, Groundnut Seed, Guar Gum Splits, Guar Meal

Oil Expeller

Get Price Quote

Oil Expeller, vertical boiler, Hammer Mill, Seed Cleaner, Flaker machine

Sunflower Oil Press Machine

Get Price Quote

Sunflower Oil Press Machine

Oil Extracts

Get Price Quote

Oil Extracts, essential carrier cold press oils

Mustard Oil Expeller Machine

Get Price Quote

Mustard Oil Expeller Machine

Oil Expellers

Get Price Quote

Oil Expellers, Diesel Engines, Generator Sets, Water Pumps

Ground nut Oil Cold pressed

Get Price Quote

Ground nut Oil Cold pressed, Soya bean oil refined