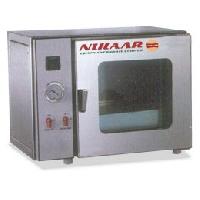

Vacuum Oven

Get Price Quote

We are one of the leading Manufacturers, Exporters and Suppliers of Vacuum Oven in the market. The Vacuum Oven that we provide is quality tested and manufactured by using the best quality raw materials, electrical parts, etc. We have got a huge array of satisfied clients, who appreciate the Vacuum Oven for its high durability and excellent performance. With us, the clients can avail Vacuum Oven in square and round shapes. Vacuum Oven (Round) Most dependable & economical – priced, chamber made of heavy gauge Stainless steel years of corrosion resistance exterior made of M.S / G.I Sheet duly epoxy powder coated finish heat treated 5 / 6mm Toughened glass window leaves clear content view. Affix on sponge type silicon gasket & positive door latch assures tight seal at all vacuum levels choices of controllers from Blind (analog), Electronic Controller, Solid State Digital Temperature controller, or P.I.D based Digital Controller at extra Cost. One needle valve to vacuuming the chamber with Vacuum Gauge that reads 0 to 30” Hg Optional Accessories P.I.D Controller will cost As per GMP model Price on requestVacuum pump will be at extra cost Vacuum Oven (Square)

Vacuum Oven

Get Price Quote

The Outer is made of M.S..The inner chamber is made of Stainless Steel and is insulated with special high grade insulation.It is suitably designed to with stand a vacuum of 760mm of Mercury. Heating is provided electrically. Easy Temperature maintain from Ambient to 200ÂşC. The unit is fitted with vacuum guage, cock but without vacuum pump. Door is fitted with toughened glass window for observations. Perforated adjustable shelves made of S.S are provided with the unit.

Best Deals from Overhead Conveyor Ovens

Round Vacuum Oven

Get Price Quote

1 unit (MOQ)

We are manufacturing & exporting of a wide range of Round Vacuum Ovens used by vacuum, these round vacuum ovens give heating to material.  Technical Specifications: Round vacuum oven are double walled Inside chamber is made of thick stainless steel S.S.304 Outside chamber made of Mild steel Powder coated High grade glass wool insulation between two walls to avoid lost of heat Uniform drying under vacuum Temp. Range 50 C to 200 C with accuracy of ± 2 C Precise vacuum guage upto 30 H2 analogue Temp controlled by digital temp controller cum indicator Vacuum chamber is wrapped with set of high quality heater for quick & uniform heating Doorv has a thick tempered toughen glass window perfectly sealed with silicon rubber gasket for observation without disturbing thermal condition Proper door alignment to ensure excellent vacuum performance & operate safety Positive screw to tighten the lid to obtain preface seal Fitted with vacuum valves & vacuum gauge Switches & indicating lamps are provided on front panel  Optional Accessories: PID Controller with printer option Programmable controller with 8 steps Round Vacuum Oven Is Available in Below Sizes:

Laboratory Ovens

22,500 - 144,500 Per unit

1 Piece (MOQ)

The Forced Convection Oven is triple walled constructed cabinet made of mild steel insulated with high quality dense insulation. The Front door is fitted on chrome plated hinges with superior locking arrangement as per cabinet dimensions.The outer finish is asthetically enhanced by suitable colour.The Inner Chamber of the ovens are available of Mild Steel/ Stainless Steel.With forced air draft by Motorised blower blowing in fresh air from three sides. There is no air recirculation.Quality Tested heating elements offers long life working controlled by bi-metallic thermostat giving accuracy ±1oC at higher temp. Temperature Range:50oC above ambient to 250oC Maximum50oC above ambient to 400oC MaximumÂ

Vacuum Ovens

Get Price Quote

These units are fitted with highly accurate controller that allows gentle drying of heat sensitive materials & highly hygroscopic materials. The vacuum ovens can dry faster than the conventional ovens & avoid damage due to rapid temperature overshooting. They come with a separate vacuum release valve to release the vacuum by gentle turn of the knob. An air release inlet is located below the tray to avoid sample disturbance due to air blowing.

Varnish Baking Oven

Get Price Quote

Laboratory Ovens

Get Price Quote

Double walled interior and exterior S.S 304 with matt finish insulated with high grade rock wool insulationAll operations through a single PID controller with 2-line LED display.S.S. Perforated Trays with adjustable Runners. Forced air circulation for uniform temperature

Vacuum Ovens

Get Price Quote

We are one of the most prominent Manufacturers, Suppliers and Exporters. Vacuum Ovens are very beneficial in gentle and careful drying of heat sensitive material thus avoiding material damage due to sudden temperature overshooting. Vacuum Ovens take considerably shorter time in drying material than conventional ovens. All Vacuum Ovens, manufactured by us, can easily release vacuum by turning off the knob inbuilt in it. Performance Features Direct contact between the sample tray and heaterHeater mounted below the tray, ensures rapid and equal heating without any thermal lossTemperature safety device, with visual alarmCalibration certificatePID controller with integrated timer 0 to 99 hours with one ramp and soak functionDigital temperature setting with an accuracy of 0.1*CThe interior and exterior of the chamber is made of stainless steel with one aluminum rackThe door is provided with silicon gasket and positive latch to maintain seal at all vacuum levelsDoor with glass window for viewing of the samples inside the chamberAudio visual alarm for temperature deviationSetable temperature deviation alarm limit User friendly Calibrated vacuum gauge and temperature controllerA separate vacuum connection valve prevent oil spilling in the ovenVacuum pump connection is provided at back of the oven

Hot Air Oven

25,000 - 75,000 Per pcs

1 pcs (MOQ)

Description: Hot Air Oven – Plov-g Series “gmp Model”, Bottom Heater :Hot Air Ovens Are Sturdy Double Walled Units. Inner & Outer Chamber Made Of S.S. Steel GRADE304 or better. Gap Between The Walls Fitted With Glass Wool Insulation To Avoid Heat Loses. Heating Elements Are Made Of High Grade Chrome Plated Nicrome Wire. •Temp. Is Controlled By Thermostat. Temp. Range 50°c To 250°c And Accuracy: ±2°c (with digital accuracy ±1°c) Air Ventilations Is Provided On The Top Of The Unit To Remove The Hot Gases / Fumes. In Lab Type Oven Heaters Are Placed In The Bottom Side Of The Unit. All The Control Switches & Pilot Lamps Are Fitted On The Front Panel. Trays Should Be Supplied With G.i.wire Mesh. Optional Accessories: Air Circulation Fan for Uniform Temperature. Digital Temperature Controller cum indicator in lieu of thermostat with an accuracy ±1°c. S.S. Trays.

industrial batch oven

Get Price Quote

industrial batch oven, Powder Coating Oven, Roller Hearth Kiln

Curing Oven

Get Price Quote

CURING OVEN 4 mtr X 2 mtrs X 2.5 mtrs fully automatic inside ss 304 outside ms with steam generator ( 20,000 panels) 3 mtr X 2 mtrs X 1.8 mtrs fully automatic inside ss 304 outside ms with steam generator ( 10,000 panels) Our Curing Ovens are designed and manufactured with precision & the highest quality in the industry. Each oven is customized to fit the customer’s requirement for productivity and safety. Alpha Solutions offer a variety of Curing oven arrangements to fit both space and production requirements. Whether you need small oven or large, Alpha Solutions can build the oven to suit your needs or you can choose from one of the many standard designs. Expandability : It start with a lower capacity and expand in 2500 panels increments up to 30000 panels. Options : There are various options available • Steam Generator• Spray Nozzles/Humidifies• High Pressure Vaporizer• Electrically Heating System• Gas Fired Heating System• Process Heat Recovery System• Advanced temperature and humidity• Monitoring and controlling system Serviceability : New diagnostics assist in trouble-shooting problems to minimize downtime and maximize quality Versatility : Our experience in building custom ovens for all industries can be put to the test if you need that special oven configuration designed to fit your needs. Our Customer knows that A S India INC. ovens can change right along with their needs. Alpha Solution’s Plate Curing Oven Features : • PLC / Microprocessor-based digital temperature controls.• Temperature recorders as standard equipment on conveyor models• Non-overloading circulation fans• Adjustable air orifices• High Temperature light fixture inside oven• Bottom to top airflow forced and natural convection heating• Access doors for inspection and maintenance• 4-inch insulated oven panel construction with steel frame• experienced service staff and large supply of spare parts. Steam Generators High pressure steam generators are essential for many industrial processes that require heating media temperatures at very high level. We are engaged in offering a wide range of Fully automatic products. These are most suitable for continuous supply of ultra-dry steam and are highly fuel efficient. What is Curing ? • The modern Trend is towards use of lead sub oxide with 30% metallic lead• The presence of metallic lead has brought significant changes in the methods of handling plates immediately after being pasted. • The need for such changes arise from the peculiar behavior of pulverized lead in the presence of air and moisture. In a perfectly dry condition, lead does not oxidize and this is equally true in case of abundance of water. • The latter condition is beneficial in operations until the actual pasting of plates. • Once the paste is applied to the grids, the residual moisture, the atmospheric humidity and ambient temperature all become significant. • The problem then is to control these three factors so that oxidation to litharge occurs and the free lead content is reduced from 25 %- 30% to less than 3% Why is curing process important ? • Proper curing improves strength of the dried plates.• It also result in proper bonding of interface between the grid and the paste .• Improper curing results in scaling or shedding of active material during formation process or service lifeWhy is curing a special process? • In battery manufacturing, curing is the special process where the result of the output cannot be verified by subsequent monitoring or measurement. As a consequence deficiencies become apparent only after the product is in use or services has been delivered. • To control the process, the following measures are required: • Defined criteria for review and approval of the process• Approval of equipment and qualification of personnel• Use of specific methods and procedure• Requirement of records• Re – validationÂ

aluminium collapsible tube drying ovens

Get Price Quote

1 piece (MOQ)

We are offering main specification production speed: ≤60pcsmin length: . the oven is used to dry the tubes printed and coated it takes around six minute in the oven to completely dry the tubes

Electric Curing Oven

Get Price Quote

Very effective for high production rate. Cure in uniform rate. Convection/Direct/Indirect/Infrared Heating System High efficient heat transfer and energy utilization. Heats by line of sight. High thermal efficiency Fine control and proper uniformity Aesthetic finishing Thermal loss is prevented by filling rock wool (Insulation) in space between the outer body & Inner chamber. Customized sizes designed to meet customers’ requirements

Vacuum Ovens

49,000 - 125,000 Per

1 Piece (MOQ)

Laboratory Ovens

Get Price Quote

We manufacture a wide gamut of industrial Laboratory Ovens such as vertical autoclave, muffle furnace, memmert type hot air oven, round vaccum oven. Quality is our forte and to ensure the highest quality standards of our products, we conduct stringent tests at regular intervals on each lot and on the products. Our company’s success is evident from its large customer base, belonging to diverse segments.

KAMBIC HIGH TEMPERATURE OVENS

Get Price Quote

1 unit (MOQ)

Hot Dip Galvanizing Plant

Get Price Quote

hot dip galvanizing plant oil removal from the surface of steel, It is immersed in acid base degreaser.To clean the surface of carry over salts for effective acid cleaning.The rust scale & mill scale are removed from the surface of the steel by passing it through 15 to 20% conc. HCL.

air circulating oven

Get Price Quote

Industrial Drying ovens are used across a range of industries and research laboratories for simple applications, such as drying and sterilizing glassware, to complex processes that require controlled heating and temperature uniformity such as bonding and curing. Temperature inside drying oven is controlled with a sensitivity of +1Deg.C or better. Indirect heating from three sides is provided with the help of air heaters. It is a technologically advanced and operator friendly solution which ensures uniform drying to consistently produce high quality product and also reduces product drying time compared to traditional drying methods.

UV Curing Oven

25,000 Per Piece

3Dware's UV Oven is used to cure Jewellery cam pieces in just 2 minutes. Push button door with a sliding tray helps the easy movement of delicate parts inside the oven. Automatic stopwatch helps to prevent overcuring of the parts.

Conveyor Ovens

Get Price Quote

Conveyor Ovens, Conveyors, industrial electric ovens

Curing Oven

Get Price Quote

After blow-drying the coated pieces are required to be cured in an air circulatory oven. The articles are required to be cured at 160 Deg. C for 20 minutes. The pieces may be either loaded on the Trolleys for convenient handling or loaded in the Oven in any suitable manner.

Industrial Oven

Get Price Quote

Gas Heated Seco Curing Oven

Get Price Quote

* Available of capacity to load 30 & 60 trousers* Supplied along with SS Trolleys Gas train* Designed to give Uniform temperature Safety to operator & load SPECIFICATION OF WRINKLE FREE BATCH CURING OVEN(LPG GAS HEATED) Oven is design to give more consistent garment temperature through out the process. All curing ovens have the important standard features. You require to consistently produce quality wrinkle resistant garment, designed and constructed for long, hard continues use.OPTIONAL-------------Â Variable speed process airflow control of or greater flexibility with garment and fabric type. 24 hours temperature chart recorder for permanent recording of the process temperature. Stainless Steel construction for easier cleaning and longer operation life. Available in Gas. Temperature control to maintain close temperature tolerance STANDARD FEATURESÂ

Pizza Ovens

Get Price Quote

Pizza Ovens, jewellery machine, Food Service Equipment

industrial electric ovens

Get Price Quote

industrial electric ovens, Conveyor belts

Industrial Ovens

Get Price Quote

Conveyors, robotics machine, shrink packing machines

Samsung Convection Microwave Oven Red

Get Price Quote

Samsung Convection Microwave Oven Red

Laboratory Ovens

Get Price Quote

Laboratory Ovens, incubators laboratory, Glassware

Ageing Test Oven

Get Price Quote

Ageing Test Oven, Plasma Thawing Bath, Cryoprecipitate Water Bath

Microwave Oven

Get Price Quote

Microwave Oven, Electronic Products, fridge, Television