Medical Gas Pipeline

Get Price Quote

Associated with a diligent professionals and smart packaging facility, we are capable to undertake standard as well as tailored packaging requirements of the clients. Our products are specially produces using premium raw materials to ensure they conform to international management systems of quality.

liquid oxygen pump

Get Price Quote

The Liquid Oxygen Pump is a single acting piston pump. It is used for filling Oxygen into Cylinders upto a pressure of 165 kgs./cm2. The drive unit is similar to any reciprocating machine with the Crank Shaft, Flywheel, Connecting Rod, Cross Head, etc.The pump is designed for assembly in air separation unit that works by pumping liquid Oxygen and gasifying the same in Heat Exchangers for final filling as gas in Cylinders. Control of liquid feed is not necessary, because the pump is designed in accordance with the plant size and the liquid produced is constantly pumped off. The Liquid Oxygen Pump consists of a stainless steel inside liner with liquid inlet and evaporated gas outlet ports. There are no valves on these ports, which are closed by the piston itself on the pressure stroke. The third outlet is the main discharge outlet with the two non-return ball valves. The two ball valves remain firmly closed during suction stroke, due to high pressure in partly filled cylinders. To ensure that these valves are fully closed, a positive pressure of about 60 kgs/cms2 must be maintained on it. When a fresh batch of cylinders is taken for filling, open the manifold valve slowly or use a spare batch of cylinders to ensure positive pressure on these valves.

Best Deals from Oxygen Gas Plant

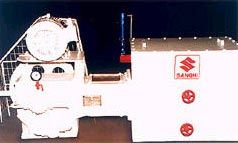

oxygen gas plant

Get Price Quote

The SANGHI-ORG Oxygen Plant, is safe and economical to operate. It comes with an efficient expansion engine, which lowers the operating pressures remarkably to as low as 32-35 kg/cm2 and also cuts down power consumption. A Molecular sieve Battery drier unit for separation of moisture and carbon dioxide is another money-saving device in the SANGHI-ORG plant. It removes acetylene and other hydro-carbons from the process air, thus eliminating the need for separate acetylene absorbers, and moreover it eliminates recurring caustic soda costs. The SANGHI-ORG Oxygen Plant is capable of simultaneously producing high purity Oxygen Gas and Nitrogen Gas. It also has an internal compression Liquid Oxygen Pump to fill dry gaseous oxygen in cylinders. We also undertake supervision of Installation and Commissioning of the SANGHI-ORG Oxygen Plant. The free atmospheric air is sucked in by a multi-stage air compressor through a filter and compressed to the working pressure. After each stage, intermediate coolers and water separators are provided. The compressed air then passes through the (evaporation) pre-cooler and then to the molecular sieve battery where the moisture and carbon dioxide are removed from the process air. It then passes through the exchanger No. 1 where it is cooled by the out-going waste nitrogen and product oxygen. A part of this cold air then flows through an expansion machine and the balance through the 2nd heat exchanger. The ratio of the two air streams is controlled by an expansion valve, RI. Both these streams of air then unite in the lower pressure column where it partially liquefies. The liquid air (rich air) then passes through the expansion valve R2 to the upper column which is at a lower pressure than the lower column. Similarly the liquid nitrogen (poor liquid) travels from the lower column to the upper column through an expansion valve R3 where the separation of oxygen and nitrogen occurs. Nitrogen being more volatile passes out as a gas from the top of the column and this waste nitrogen flows through both the heat exchangers cooling the in-coming air. Similarly product oxygen is also passed through the two heat exchangers to cool the in-coming air and then to the filling manifold via a liquid pump. If a small amount of air is vented out from the upper column, higher purity nitrogen can also be obtained from this plant. R4 Valve is provided in order to fasten cooling during start-up.

Emergency Oxygen Units

Get Price Quote

Emergency Oxygen Units Wall Mount for Recognition and Accessibility, always available on display for easy access, Constant Reading Supply Gauge (other units must be turned on to read gauge), Cylinder is easily disposablereplaceable or refillable at local gas distributors.

Multi Valve Manifold

Get Price Quote

The Multiport Selector Valve (MSV) is an engineering device that provides a cost effective and compactmeans to improve production management and well optimization. The EXACTA MSVallows the diversion of fluids from a single flow line to a test outlet or a sampling device. A single MSV can manifold as many as seven flow lines through it simultaneously. While one inlet is isolated, the flow from the other six is combined into a separate group outlet.This unique flow selector can be used in a variety of oil and gas or process applicationseither as a standalone device or with a multiphase meter. The MSV can alsobe used for water injection for Enhanced Oil Recovery (EOR) projects. It providescontrol simplicity in an environment where size, weight and reliability are all keyfactors. The EXACTA Multiport Selector VALVE reduces the costs of installation, operation andmaintenance of the well test system throughout its life cycle.One single MSV can be used as replacement of an entire arrangement of 2 or 3 way valves for a test well Selecting system, functioning as a compact manifold providing an easy and safe way to select the wells you wish to connect to the Multiphase meter or to the test Separator.

Air Header

Get Price Quote

We offer Air Headers that replace many unit valve assemblies that normally operate from one source. The Air Headers are suitable for use with a variety of outlet take-off valves. The inlet-connection can be screw-able. The drain-valve of the system is at the manifold exit and the manifolds can be supplied with a bracket or U clamp for ease of wall mounting.

Auto LPG stations

Get Price Quote

Aegis Autogas are exclusive world-class imported Auto LPG stations, Present across 10+ states of India & expanding with its specialized in-house dedicated team of experienced maintenance engineers who ensure best services are provided in real time, always Achieve Faster Project Break Even with Aegis Autogas

Headspace Oxygen Analyzer

Get Price Quote

PSA Oxygen Gas Plant

Get Price Quote

In the PSA BASED Oxygen Gas Generation Process, the compressed air is fed to the twin towers filled with zeolite molecular sieves which separate oxygen from rest of the constituent of air. The oxygen generated is 95% pure. When oxygen saturates from one tower, this process changes over to the other tower, thus helping in the process of continuous oxygen generation. . Such kind of the plant is generally installed in the Copper smelting, Sewage treatment Industry and paper industry etc.

MGL Downstream Gas Pipeline

Get Price Quote

Our firm has been approved by M/s. Mahanagar Gas Limited (MGL) for installation of Downstream Gas pipeline for Commercial & Industrial Applications. We have carried out many Natural Gas installations in recent years. The same installation has been Audited, Certified and Commissioned successfully by the MGL officials.

Multi-Air Manifold

Get Price Quote

Multi-Air Manifold, Multi-Port Gauge Valves, Back Ferrule

Medical Gas Pipeline

Get Price Quote

Medical Gas Pipeline, medical humidifier bottle, Medical Oxygen Concentrator

gas filling machine

Get Price Quote

gas filling machine, Organic Solid Waste Odour Control Misting System

dissolvo oxygen analyser

Get Price Quote

dissolvo oxygen analyser, Electronic Instruments, Spectroscopy

Purge Systems for hazardous location

Get Price Quote

Purge Systems for hazardous location, Cabinet Type Air Conditioners