Worm Gearboxes

P.G.DRIVE’s standard series worm gear unit is a proven design. These robust worm gear units are used in the industry because of their proven track record and high reliability. The worm gear units are offered in various mounting configuration which makes it versatile for any kind of application. The small units are Rib Cooled whereas the larger units are offered with Fan Cooling. P.G.Drive has now developed a new line of worm gear units with Aluminum die casting housing. These units are offered in 2 series “PVF” and “W” series worm gear reducers and geared motors. These gear units are available in various input and output mounting configuration. The input shaft is hollow with flange provided for mounting standard size IEC motor or solid shaft is provided in case a customer desires to use coupling connection. The output shaft is also available in hollow and solid configuration with foot, flange or direct face mounting configuration. The unique design features in this series includes

...more

Worm Gear Motor

P.G DRIVE’S worm gears are milestones for the industry. Flexibility is given by the wide choice of several mounting options, shaft configurations and motor interface, all offered as standard.Standard Series:P.G.DRIVE’s standard series worm gear unit is a proven design. These robust worm gear units are used in the industry because of their proven track record and high reliability. The worm gear units are offered in various mounting configuration which makes it versatile for any kind of application. The small units are Rib Cooled whereas the larger units are offered with Fan Cooling. Modern SeriesP.G.Drive has now developed a new line of worm gear units with Aluminum die casting housing. These units are offered in 2 series “PVF” and “W” series worm gear reducers and geared motors. These gear units are available in various input and output mounting configuration. The input shaft is hollow with flange provided for mounting standard size IEC motor or solid shaft is provided in case a customer desires to use coupling connection. The output shaft is also available in hollow and solid configuration with foot, flange or direct face mounting configuration. The unique design features in this series includes.• The housing is aluminum die casted for sizes 45 to 63 and high strength cast iron for 76 to 150.• The worm shaft is made of high alloy steel; case hardened and profile ground to ensure high efficiency.• The worm wheel is machined from special alloy phosphorus bronze material.• The output of all units are provided with high capacity tapered roller bearing.

...more

Worm Flange Mounted Gear Motor

P.G.Drive offers Heliworm geared motors with hollow and solid shaft output configuration. The design offered is compact and highly efficient to attain low speed. Output shaft is placed at right angle, in order to motor shaft or input shaft. The gearbox is provided with two mounting faces that are at right angle to each other & with identical mounting dimensions. The first stage reduction is achieved by helical gears, which is followed by worm gear reduction. We offer our Heliworm geared motors with output shaft at both ends. The Heliworm gear reducers are offered in foot, flange and direct face mounted configuration. Features• Graded cast iron housings• Alloy steel gears for high strength & durability• Worm : steel hardened & profile ground• Worm wheel: graded phosphorus bronze• Taper roller bearings on input and output shaft• Dc or ac supply• Flame proof and brake motor options• Single or dual speed motor• 3 Decades of field experience in Textile, Pharmaceuticals, Chemical, Cement, Sugar, Plastics, Rubber & Allied Industry.

...more

vfd drive

Variable Speed Drive, Ac Drives, DC drives, process monitoring & control systems, PLCHMISCADA based systems, PC based automation systems, soft starters, etc. Our range of variable frequency drives (VFDs) are used for controlling the rotational speed of alternating current (AC) electric motor.• Energy Savings with Variable Speed Drives • Variable Torque Versus Constant Torque • Why Variable Torque Loads Offer Great Energy Savings • Energy Consumption

...more

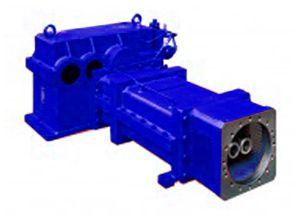

Twin Screw Extruder Gearboxes

• Highest gearbox structure strength ensures minimum rotation vibration. • High torque and high output speed rate design. • Thrust bearing coupled in tandem way. • Precision gear grinding to keep operation noise below 80db. • Forced lubrication and built in cooling & filter system to ensure excellent heat dissipation. • Top quality barings form reputed manufacturers like SKF and or ZKL bearings. Corresponding to the increasing demand of the twin-screw extruder, P.G DRIVE had developed the series of high performance gearboxes for the twin-screw extruder. Extruders are commonly used equipment used in the industrial production of plastics. Twin Screw extruder’s machines require highly sophisticated gearbox to drive the co-rotating or counter rotating extruder screws. The design requires delivering the highest possible torque evenly in both the screws by utilizing the smallest amount of space. P.G.Drive with its reach experience in the gearing field has now indigenously developed its “TE” series of counter rotating and co rotating gear boxes. The gear unit consists of four sections, the reduction gear unit, thrust housing, distributor gear unit and adapter housing forming the connection with the extruder machine.

...more

single screw extruder gearboxes

The robust and universal mounting design offers the customer with the best available product in the market today. The outstanding product quality and P.G.Drive technical know-how in the field of developing gear boxes for the plastic industry makes us the preferred partner for extruder plant builders.

...more

Planetary Gearboxes

P.G.Drive offers “PS” series planetary gearboxes and geared motors. We started the design and manufacturing of these gear drive as an import substitute, hence the product manufactured by us is functionally superior and mechanically sound planetary-geared motors. These highly efficient planetary geared motors are available with us in a cost effective manner & serve various purposes in diverse fields including, mills, plastics, textile, machine tools, paper, cement, pharmaceuticals and leather.

...more

PIV Gearboxes

PIV stands for "Positive Infinitely Variable" drive, the name given to a power transmission system using a slatted steel chain. The P.G Drive’s (PG–U series) gear is the 'classic' infinitely variable speed gear units. The simple and efficient PIV variator is a good alternative to an electric drive: from machine tools to paper production lines, from packaging machines to pump drives. Due to the negligible power losses the variator performs with very high efficiency, even when running under partial load.The most important features are:• Simple maintenance and high efficiency that enables economical solutions, even in continuous operation, & high speed setting accuracy.• The features of the 'torque converter' permit high torques at small speeds.• High control precision• High system protection for operation in dirty environments.• Continuous oil lubrication• Suitable for horizontal or vertical mounting• Operationally reversible

...more

piv gear boxes

• Simple maintenance and high efficiency that enables economical solutions, even in continuous operation, and high speed setting accuracy. • The features of the 'torque converter' permit high torques at small speeds. • High control precision • High system protection for operation in dirty environments. • Continuous oil lubrication • Suitable for horizontal or vertical mounting • Operationally reversible “PIV stands for "Positive Infinitely Variable" drive, the name given to a power transmission system using a slatted steel chain. The P.G Drive’s (PG–U series) gear is the 'classic' infinitely variable speed gear units.The simple and efficient PIV variator is a good alternative to an electric drive: from machine tools to paper production lines, from packaging machines to pump drives. Due to the negligible power losses the variator performs with very high efficiency, even when running under partial load.

...more

Parallel Shaft Helical Gear Reducers

P.G.Drive now offers parallel shaft helical gear reducers. The universal mounting design finds versatile use in all industries. The series has been developed on a platform similar to the extruder gearboxes and the range offered is comprehensive. The UHB series is the first product to prove equally good in regard to efficiency and versatility within a highly competitive context, both performance- and price-wise.

...more

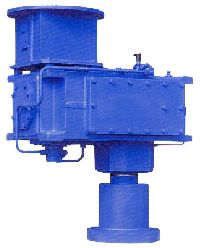

Industrial Gearboxes

P G Drive provides rugged Power Transmission Equipment serving Materials Handling, Mining and Milling, Water and Waste water Treatment, Power, Cement, Marine, Plastics, Manufacturing and general industrial applications on a world wide scale. P G DRIVE, a name accepted Worldwide for Quality. P G Drive currently makes Industrial gearboxes up to 500 KW. P G Drive provides rugged Power Transmission Equipment serving Materials Handling, Mining and Milling, Water and Wastewater Treatment, Power, Cement, Marine, Plastics, Manufacturing and general industrial applications on a world wide scale. P G Drive currently offer Aerator gearbox as per industries standard or as per customer specific requirement for ETP treatment plants.

...more

heli worm gear boxes

P.G.Drive offers Heliworm geared motors with hollow and solid shaft output configuration. The design offered is compact and highly efficient to attain low speed. Output shaft is placed at right angle, in order to motor shaft or input shaft. The gearbox is provided with two mounting faces that are at right angle to each other & with identical mounting dimensions. The first stage reduction is achieved by helical gears, which is followed by worm gear reduction. We offer our Heliworm geared motors with output shaft at both ends. The Heliworm gear reducers are offered in foot, flange and direct face mounted configuration.

...more

Helical Inline Gear Boxes

P.G.Drive manufactures “P” Series Inline Helical Gear reducers and Geared Motors. These units are available in Foot, Flange and Co-axial type construction. The gear reducers available are suitable for mounting any standard IEC frame electric motor in B5 construction. The product range offers low installation cost, low noise operation, high efficiency and balanced performance.

...more

HARDENED GROUND GEARS

P G DRIVE is a leading Manufacturer & Exporter of Custom Cut and Ground Gears. The P G DRIVE is capable of manufacturing all types of gears cut or precision ground. With products including precision ground helical gears, spur, and gear sets, there isn't a project we can't handle. Whether we're manufacturing your gear complete from start to finish or working from your blanks, our wide range of precision gear manufacturing capabilities and services deliver quality gears to meet almost any application.

...more

Gearbox Repairs

At P G DRIVE we are experts when it comes to rebuilding heavy industrial gearboxes. We don't just fix your problems; we use detailed analysis to find out why things went wrong in the first place. We also take into account increased operational demands. To learn more about our cost-effective and efficient gearbox rebuilding service, please see the details below. For information about the rest of our services, please contact P. G. DRIVE today. Inspection P G Drive utilizes modern state of the art inspection equipment, to inspect incoming gearbox components for reverse engineering and manufacturing purposes.

...more

extruder gearboxes

We are Manufacturers, Exporters & Leading Suppliers of Single Screw Extruder Gearboxes. The “E” series single screw extruder gearboxes offered by P.G.Drive have made a prestigious name for itself in the field of plastic extruder industry. The robust and universal mounting design offers the customer with the best available product in the market today. The outstanding product quality and P.G.Drive technical know-how in the field of developing gear boxes for the plastic industry makes us the preferred partner for extruder plant builders.

Specialities : Maximum Torsion Stiffness Gear Housing.

...more

Custom Gearboxes

As a leading custom gearbox manufacturer with over 30 years of gearbox engineering and gearbox design experience, P G Drive can bring your custom engineered solutions to life. 3 reasons to choose P G DRIVE for your custom gearbox projects: 1. Really Custom Made P G Drive is able to build a custom specific gearbox that fits seamlessly into your design with no adjustments. Completely customized to your individual needs. 2. over 30 years of Experience We combine over 30 years of experience with innovative manufacturing facilities and an extensive design and development knowledge to deliver what the customer needs. 3. A New Gearbox Within 3 Months Our service-oriented mindset allows us to design and manufacture a custom made gearbox much faster than other gearbox manufacturersOEM’s. Today's industrial gears operate at faster speeds, carry greater loads and demand higher operating efficiencies than did their predecessors. Downtime is expensive, and in a competitive business environment it just doesn't pay to continue to repair a gearbox that suffers repeated failure.

...more

Bevel gears

Spiral Bevel Right Angle Gears are most commonly used to transmit power between shafts that are at a right angle or 90 degree orientation to each other - although almost any shaft angle is possible. There are serious benefits to the spiral bevel design. With these gears, the gear teeth gradually enter into mesh during rotation until maximum mesh is achieved. The teeth then leave mesh in the same manner. The payoff is that these gears run smoother, quieter, and have greater load capacity than straight tooth bevel gears.

...more

Axial Helical Gearbox

P.G.Drive manufactures “P” Series Inline Helical Gear reducers and Geared Motors. These units are available in Foot, Flange and Co-axial type construction. The gear reducers available are suitable for mounting any standard IEC frame electric motor in B5 construction. The product range offers low installation cost, low noise operation, high efficiency and balanced performance.• Foot mounted gear reducers & gear motors.• Flange mounted gear reducers and gear motors• Coaxial gear reducers• Multistage gear reducers and geared motors Features:• Graded cast iron housings• High strength alloy steel gears• Single & three phase motor• DC or AC supply• Flame proof and brake motor options• Single or dual speed motor• 3 Decades of field experience in textile, pharmaceuticals, chemical, cement, sugar, plastics, rubber & allied industry.• More than 10000 + inline helical gearboxes in operation in the industry.

...more

Inline Helical Gearbox, Geared Motor

1 Piece(s) (MOQ)

We are offering inline helical gearbox, geared motor. p.g.drive manufactures “p” series inline helical gear reducers and geared motors. These units are available in foot, flange and co-axial type construction. The gear reducers available are suitable for mounting any standard iec frame electric motor in b5 construction. The product range offers low installation cost, low noise operation,high efficiency and balanced performance. foot mounted gear reducers & gear motors. flange mounted gear reducers and gear motors coaxial gear reducers multistage gear reducers and geared motors manufacturing range: power: 0.25 hp to 10 hp output speed: 15 rpm to 400 rpm the lower output rpm range is offered by multistage combination gear units up to 0.1 rpm. power: 0.25 hp to 3 hp output rpm: 15 rpm to 0.1 rpm

...more

Flange Mounted Inline Helical Gearbox, Geared Motor

1 Piece(s) (MOQ)

We are offering flange mounted inline helical gearbox, geared motor. p.g.drive manufactures “p” series inline helical gear reducers and geared motors. These units are available in foot, flange and co-axial type construction. The gear reducers available are suitable for mounting any standard iec frame electric motor in b5 construction. The product range offers low installation cost, low noise operation,high efficiency and balanced performance. foot mounted gear reducers & gear motors. flange mounted gear reducers and gear motors coaxial gear reducers multistage gear reducers and geared motors manufacturing range: power: 0.25 hp to 10 hp output speed: 15 rpm to 400 rpm the lower output rpm range is offered by multistage combination gear units up to 0.1 rpm. power: 0.25 hp to 3 hp output rpm: 15 rpm to 0.1 rpm

...more

Coaxial Inline Helical Gearbox, Geared Motor

1 Piece(s) (MOQ)

We are offering coaxial inline helical gearbox, geared motor. p.g.drive manufactures “p” series inline helical gear reducers and geared motors. These units are available in foot, flange and co-axial type construction. The gear reducers available are suitable for mounting any standard iec frame electric motor in b5 construction. The product range offers low installation cost, low noise operation,high efficiency and balanced performance. foot mounted gear reducers & gear motors. flange mounted gear reducers and gear motors coaxial gear reducers multistage gear reducers and geared motors manufacturing range: power: 0.25 hp to 10 hp output speed: 15 rpm to 400 rpm the lower output rpm range is offered by multistage combination gear units up to 0.1 rpm. power: 0.25 hp to 3 hp output rpm: 15 rpm to 0.1 rpm

...more

Helical Extruder Gearbox

1 Piece(s) (MOQ)

We are offering helical extruder gearbox. single screw extruder gearboxes: the “e” series single screw extruder gearboxes offered by p.g.drive have made a prestigious name for itself in the field of plastic extruder industry. The robust and universal mounting design offers the customer with the best available product in the market today. The outstanding product quality and p.g.drive technical know-how in the field of developing gear boxes for the plastic industry makes us the preferred partner for extruder plant builders. The product features: maximum torsion stiffness gear housing inbuilt thrust bearing universal mounting configuration long life transmission elements integrated cooling system maximum operating reliability low noise & smooth running manufacturing range: the single screw extruder gearboxes are offered in 2 series: the single stage gearbox is offered in ratios from 4 to 6.3 with the torque range from t2 = 1400 nm to 5200 nm calculated at the standard ratio of 5:1. the two stage gearbox is offered in ratios from 10 to 18 with the torque range from t2 = 585 nm to 10,000 nm calculated at the standard ratio of 14 or 16:1. other ratios are offered per the customer request.

...more

Parallel Shaft Helical Gearbox

1 Piece(s) (MOQ)

We are offering parallel shaft helical gearbox. parallel shaft series: p.g.drive now offers parallel shaft helical gear reducers. The universal mounting design finds versatile use in all industries. The series has been developed on a platform similar to the extruder gearboxes and the range offered is comprehensive.

...moreBe first to Rate

Rate ThisOpening Hours