Automatic Collar Type FFS Machine

Get Price Quote

1 Piece(s) (MOQ)

Our Automatic Collar Type FFS Machine boasts of an impressive power of 1-2 HP. With the assistance of our secure payment procedures including both Online and Offline Payment Processing, we are able to ensure safety of the payments with us. Sourced from trustworthy vendors, our entire lot of raw materials has been cross checked against varied quality parameters before using them in the production process.

Chakali Packaging Machine

Get Price Quote

This model is specially designed for Flow wrap which is best suited to wrap 2, 3 & 4 stacks of Chakali, Soan Papdi and biscuit. The machine is suitable for Chakali. These machines are manually feeding packing machines. The end sealing and cutting is done by rotating hot jaw.

Best Deals from Packaging Machine

blister packaging machine

Get Price Quote

Blister Packaging Machine Model BPM-500 has been widely used for the package of hardwares, toys, daily used articles and electrical elements. The commodity packed is featured as transparent, damp proof, dustproof, secure and pleasing to eye.

Welding Machine

Get Price Quote

We, Sparkweld Engineering, Mumbai, are manufacturer and supplier of world class Utensil Stud Welder (Pan Welding Machine). With the diverse application in its portfolio, Pan Welding Machine serves the variety of kitchenware manufacturer in India. The main feature is excellent aesthetic in welding. Pan Welding Machine serves simple as well as a complex application so won the trust of kitchenware manufacturer as they want the latest technology to create best and innovative products. Our specialized Pan Welding Machine efficiently serve the vast diversity of kitchenware which is key to growth and profitability of every manufacturer. Features: Excellent aesthetic in welding. Fully pneumatic control and pneumatic lift facility. Easily adjustable height. Robust and lightweight. Aluminium construction to restrict magnetic influence. Different angle adjustment on welding head and pan bolster for angled welder fixings. Adjustable air control and interchangeable bolster arrangement. For the correct stud position on pan wall, linear movement of the front plate is provided. Specifications: Brand: Sparkweld Engineers. Product Code: SE-06. Type: Stored Energy Discharge. Welding Head Operation: Pneumatic. Welding Head: Initial Contact Type. Stud Range: Up to 10mm square aluminium. Base Material:1.2mm and above. Gas: Argon 99%. Input Supply Voltage: 240v,A.C.,10Amp. Charging Voltage:60 to 180 volts, D.C., Stepless.

Biscuit Packing Machine

455,000 Per Number

1 Number (MOQ)

Vacuum Packaging Machines Mini

Get Price Quote

We are offering Vacuum Packagin Machines. Technical Specification : » Seal Length : 500mm » Chamber Size : 575 x 575 x 60Dmm » Seal Width : 8 » No. Of seal bar : 2 » Approx Packing Qty. One Shoat : 4 No. » Approx Packing Time Of One Shoat : 45-60*sec. » VACUUM PUMP 280Lt. (Toshniwal Make) : 1 H.P. » Overall Dimensions Approx : H800 x W680 x D750mm » Power Supply 3phase 415vac 50Hz. : 1 HP » Weight approx : 250Kg. Standard Features : » Programmable Digital Control Panel. » Flat working surface for easy operation. » Stainless Steel Housing. No Sharp Edges. Easy To Wipe. » Cutout of Toughened Glass to View the Packaging Process from the Top. » Entirely Made from Stainless Steel, Cast Aluminium & other non ferrous materials. » Oil Mist Separator to remove the Oil mist from Vacuum Pump exhaust. » Soft ventilation – A gradual air influx for ventilation process to compensate Pressure to save the product appearance and material.

chamber machine

Get Price Quote

We have four models of chamber machines designed for customers with different production needs to reach an optimum ratio price/performances and reliability in time. Different production requirements are satisfied by the four distinct chamber machines models. Standard shrinking magnet assembled on machine, washable stainless steel lower chamber to grant better hygiene in foodstuff packing, six working programs available directly by the electronic control panel that drive all machine functions (and automatically adjust sealing time, avoiding fumes caused by sealing blade overheating), sealing by adjustable impulse blade, security thermostat with warning signal to find out troubleshooting, sliding trolley and adjustable working surface, film micro puncher, motorized winder, are the features of FM range. Two working possibilities (sealing only or sealing + shrinking).

SPL-20-WH- Semi Automatic Sleeve Wrapper (Pneumatic)

Get Price Quote

1) Suitable for wrapping of such products as pop-top, mineral water, bottles, beer, drinks both with and without bottom-tray 2) Working with PE shrink tunnel to pack the goods perfectly 3) The whole producing process adopt the Germany advanced techniques. Parameter: Specifications: Model: SPL-20-WH-(Pneumatic) 1) Power: 220-240V, 50-60Hz;1.8KW 2) Packing speed: 2-5pcs/minute 3) Sealing time/shrink time: 0.5-1.5s, 0-0.6s 4) Conveyor loading: 30kg 5) Shrink film: PE, POF, PVC, PP 6) Film width: max. 500mm 7) Film thickness: 0.04-0.12mm 8) Dimensions: 1020 x 830 x 1980mm 9) Packing: Max. packing dimensions: 450 x 270 x 350mm Min. packing dimensions: 250 x 60 x 60mm

paste filler

Get Price Quote

Semi Automatic Paste fillers are uniquely designed semi automatic machine for thick homogeious pastes and viscous material. Easy adjustment to nullify Batch variations of Paste charecteristics help achieve higher accuracy. Provision for stirrer driver helps to push material in the hopper resulting in reduced buid up of material on side wall of hopper walls and increase accuracy. Various models are available based on the application requirements

Protective Packaging Machine

Get Price Quote

Juice - Candy & Liquid Packing Machine VE-FFS-200

Get Price Quote

The Vijay Engineering Liquid Filling VE-F.F.S-200 Series Vertical Packaging machine which automatically forms a bag, Fill's it, then seals and Separates the Finished Packets. The VE-F.F.S-200 is suitable for all kinds of Low density like Juice, Oil, Milk, Mineral Water & any type of free Flowing liquids. The Vijay Engineering Vertical form fill and seal machine (F.F.S) is robust with particular consideration for minimum maintenance easy to adjust and high reliable output. All Contact parts are manufactured by stainless steel. This Machine Constructed with unique feature, Which is easy to operate for the Customers.

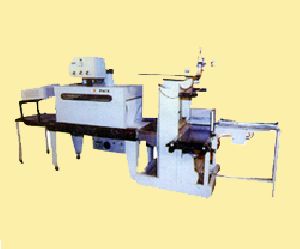

Automatic Shrink Packaging Machine

Get Price Quote

Automatic Sleeve Wrapping Machine

Get Price Quote

ADVANTAGES : * No use of bottom tray * No manual Interaction

horizontal flow wrap machines

Get Price Quote

This Model is suitable to pack products in 1/2/3/4/5 piles of biscuits. The same Model can also be used for paking tray type or for Pre-wrapped Products. Lug carries required number of products from the magazine and arrives to the forming box. The wrapper is wrapped around the forming box. Fin seal at bottem is completed by three pair of rollers out of which one pair is for pre heating, second for heating and third for propelling purpose, which controls the wrapper around the periphery of the product. The crimping jaws makes cross sealing at two ends and seperation as required, such packets are delivered to the out feed conveyor. Automatic self contained unit. All components coming in contact with product are of stainless steel or Food Grade plastic. Ease of change over to differnt varieties of product in minimum time. A.C. motor with variable frequency Inverter Drive. Separate Temperature Controllers are provided for each pair of Heating rollers and jaws. Cut off Length adjustment by just rotating wheel with Display. Simple to operate and easy to maintain.

Automatic Chips Packing Machine

265,000 Per unit

1 unit (MOQ)

Vertical Form Fill Seal Machine

510,000 Per

Blister Packing Machine

Get Price Quote

In-built dust collection. Infrared photo controller for feeder unit. Universal type batch-code printing unit. Contact heating system with separate pneumatic operation. Packing any size of Tablet/Capsule/Tabsule.

Welding Machine

Get Price Quote

Automation is a must for all industries today. Increasing competition calls for more and more automation in fabrication industries where metal cutting and welding is involved. There is hardly any application which is not possible to automate technically. The quality, speed, consistency and economy is possible only with automation. The basic building block for automation in industrial application is motion control. Addition of vision technology has widened the area of application.

Groundnut Kernels

Get Price Quote

We are offering Groundnut Kernels. we are accounted as one of the largest groundnut kernels manufacturers and exporters in the global market. our groundnut kernels are commonly used as oil seeds in all over the globe. the raw groundnut kernels, offered by us, are applauded for their excellent taste due to which they are also used in confectionery items and different snacks items. types available java and bold types specifications appearance : round pinkish/reddish color seeds taste & odor : typical, no sour taste or odoroil content : contain 44-47 % of oil packing25/50 kg jute bags.

Groundnut Kernels

Get Price Quote

Groundnut is the major oilseed of India. It accounts for around 25% of the total oilseed production of the country. Annual production of Indian Peanuts and Indian Peanuts oil are around 5-8mln and 1.5 mln tons respectively. Peanuts Production is highly vulnerable to rainfall deviations and display huge fluctuation between years. Regional estimates are Gujarat (1-3.5 million tons), Tamil Nadu (1million tons), Andhra Pradesh (1-2 million tons), Karnataka (0.5 million tons), Maharashtra (0.5 million tons) are the major producers of Peanuts. Around 75% of the crop is produced in khariff (June - September) and remaining 25% in rabi (November - March). India exported around 100000 tons of groundnut oil in 2003-04 after 4 decades, as crop failed in Senegal and Argentina. Peanuts or Groundnut kernels are approx. 70% of weight in shells and kernels have an oil recovery of 40-42%. China (2-2.5 million tons), India (1.5-2 million tons) is the major producers of groundnut oil, followed by Sub-Saharan African countries and Central and South America. Global trade of Peanuts or Groundnut oil is to the maximum of 100000 tons a year. EU and US are major importers. Senegal and Argentina are the major Peanuts exporters. Factors Influencing Peanuts or Groundnut Markets Weather at the major domestic producing centre. The southwest monsoon is the most important factor that determines the area sown, production and prices. Price of other competitive oils in India, viz., soy oil, palm oil, cottonseed oil, sunflower oil and mustard oil. International price movement of soy oil at CBOT and palm oil at BMD, Malaysia also influence the groundnut oil prices. Festivals and celebrations also increase consumption and the prices.