Knee Milling Machine

Highly versatile machine capable of performing complex operations Table has 3 nos. T-Slots, with a graduated scale to obtain exact angle up to ±45º Working pressure of the table lead screw is through pressure-thrust bearing The heavy knee is made as a box and rests on a vertical column equipped with thrust bearings Hardened & ground gears, arbors, spindle and shaft The vertical head can swivel ±90º Bigger motor available on request Accuracy: As per IS Standard 2201Surface milling by automatic longitudinal movement and manual vertical displacement is 0.005mm/200mm on flat surface 0.01mm/200mm on perpendicular surface Application: Machining flat surfaces, contoured surfaces, surfaces of revolution, external and internal threads, and helical surfaces, of various cross sections Face Milling, Perpendicular Milling, Slotting, Rack Cutting, Hobbing, Gear Cutting, Drilling, Boring Accessories:Swivel Base Vice, Rotary Table, Collet Adaptor, Collets, Clamping Kit, Long Arbor, Stub Arbor, Digital Read Out

...more

Double Column Vertical Lathe

Heavy duty Double Column VTL The bed is of single piece casting. A table guard protects the operator from flying chips. The thrust bearing on table carrier takes the downward thrust of work piece. Tipping forces are countered with radial bearing. Single piece box type column comes with corrosion resistant telescopic covers to protect the guide ways Motorized Up-Down movement of Cross Rail with one ram head with ± 30º swivel Centralized control station with interlocked electrical control panel Accuracy: As per IS Standard 2063 Roundness using Turret Head/ Ram Head/ Side Head is 0.02mm/ 300mm diameter Flatness for facing operation 0.02mm/300mm diameter in concave direction only Application: Machining of large and heavy components such as parts of engines, turbines, transmissions Machining large asymmetrical work pieces that are difficult to clamp on a horizontal lathe Accessories:Additional ram head on cross rail, Turret head on cross rail, Threading head on cross rail, Side ram head, Milling attachment, Grinding attachment, Coolant system, Complete guard, Chip conveyor

...more

Universal Milling Machine

Description: Universal Knee Type Milling Machine Highly versatile machine capable of performing complex operations Table has 3 nos. T-Slots, with a graduated scale to obtain exact angle up to ±45º Working pressure of the table lead screw is through pressure-thrust bearing The heavy knee is made as a box and rests on a vertical column equipped with thrust bearings Hardened & ground gears, arbors, spindle and shaft Heavy pair of braces holds the arbor and over arm to ensure accuracy under heaviest cut. Bigger motor available on request Accuracy: As per IS Standard 2200Surface milling by automatic longitudinal movement and manual vertical displacement is: 0.005mm/200mm on flat surface 0.01mm/200mm on perpendicular surface Application: Machining flat surfaces, contoured surfaces, surfaces of revolution, external and internal threads, helical surfaces, various cross sections Face Milling, Perpendicular Milling, Slotting, Rack Cutting, Hobbing, Gear Cutting, Drilling, Boring Accessories:Vertical Milling Head, Universal Dividing Head, Swivel Base Vice, Rotary Table, Collet Adaptor, Collets, Slotting Attachment, Rack Cutting Attachment, Hobbing Attachment, Micro Boring Head, Clamping Kit, Long Arbor, Stub Arbor, Digital Read Out

...more

Universal Cylindrical Grinding Machines

Hydraulic table traverse with infinitely variable speed range, Work head swivel of ±90º with rapid approach for easy operation, The slides are coated with “Turcite-B” linear bearing material to give stick slip free movements, reduce vibration and improve repetitive positioning accuracy, Hand-operated lubrications pump for sufficient lubrication of Slides.

...more

Universal Cylindrical Grinder

Description: Hydraulic Universal Cylindrical Grinding Machine Hydraulic table traverse with infinitely variable speed range Work head swivel of ±90º with rapid approach for easy operation Wheel head swivels ±45º, allowing conical and angular grinding The slides are coated with “Turcite-B” linear bearing material to give stick slip free movements, reduce vibration and improve repetitive positioning accuracy Hand-operated lubrications pump for sufficient lubrication of Slides Specifications: (In mm unless specified otherwise) Accuracy: As per IS Standard 2368 Surface finish 0.002 mm/100 mm True Run Out of Spindle Taper: 0.005 mm Applications: Face grinding, Transverse grinding, Taper grinding, Plunge grinding, Angle grinding, Internal grinding Automobile components, Bearings, Rollers, Fasteners, Tool Room, Dies & Punches Accessories:Internal Grinding Attachment, Balancing Stand with Mandrel, Steady Rest, Radius Truing Device, 4-Jaw Chuck, Magnetic Coolant Pump, Grinding Gauge

...more

Tool Room Lathe

Description: All Geared Lathe Graded Casting with Hardened & Ground Guide ways Hardened & Ground Spindle and Gears in Headstock Cam lock Spindle Nose is standard Universal Feed Box of toughened EN-8 material with inch, mm, DP and Module thread Gap Bed is standard Specifications: (In mm unless specified otherwise) Accuracy: As per IS Standard 1878 (Part-I) Work piece on Chuck (Turning)-Roundness of 0.01mm taper near headstock Work piece between Centers (Facing) Flatness of 0.02mm/ 300mm length in concave direction Applications: General purpose lathe useful for versatile operations- turning, facing, threading, taper turning Tool room operations and machining of small work pieces & shafts Accessories:Self Centering Chuck, Independent Jaws Chuck, Steady Rest, Follow Rest, Revolving Center, Digital Read Out, Taper Turning Attachment, Grinding Attachment, Electromagnetic Footbrake, Milling Attachment

...more

Thermal Drilling

Introduction: Thermal Drilling Technology for Sheet Metal Drilling & Tapping What is Thermal Drilling: Making Holes without Removing Material Drilling holes removes metal from the work piece If the metal is retained, the hole becomes stronger It can allow formation of a collar which can be tapped or used as a through hole for welded, soldered or brazen connections Thermal Drilling Process:Formdrill® tools are made from Tungsten Carbide. Their conical body has specially developed lobed geometry. Thermal drilling process is a method of making a hole and simultaneously producing a bush from the parent metal to give additional support as a bearing surface or for a thread. Make a hole and form a bush in one operation.Frictional heat is generated by speed and pressure to form the material.Fast cycles(2-4 sec for M8-M10 holes The completed bush gives additonal support as a bearing for a thread.Threads are produced by roll forming. No material is removed.Strong connection with no parts to break free improves joint connection. Advantages of Thermal Drilling Process: Versatile Useful for malleable material – mild steel, stainless steel, copper, aluminum, etc.Useful for Tubes, Pipes, Angles, Channels, Flats of wall thickness 1-10 mm (M.S.) Fast Increase Production with Faster Cycle Time: M8-M10 holes within 2-4 seconds Strong Improvement in quality by creating stronger joints having pull out strength greater than DIN Standard for Welded Nut Secure No inserts to break freeCleaner Working Environment due to Chip-less Process Cost Eliminates usage of welded nuts, threaded inserts thereby reducing cost Easy to Use Easy to UseCan be used with any good quality Pillar Drill, CNC Drilling, Precision Milling, CNC Machining Center, with good spindle bearings, adequate spindle speed and power.

...more

Slotting Machine

he column has a deep throat to enable a variety of parts to be machined the circular table is provided with t-slots 360º direct indexing to accurately locate positions a taper hole in the center of the table is useful for reception of cantering mandrel while machining circular slotting work. steel gear slide on multi-spline shafts. All shafts are carried on ball bearings. accuracy: as per is standard 2308 perpendicularity of the ram movement to table surface in longitudinal direction 0.02mm/300mm perpendicularity of the ram movement to table surface in traverse direction 0.02mm/300mm application: cutting slots, splines, keyway- internal and external machining internal and external gears, concave, circular, semi circular and convex surfaces, dies, punches shaping internal and external forms or profile internal machining of blind holes machining of shapes which are difficult produce on shaper accessories:±5º tilting head, auto feed for x & y axes, auto rotary feed, bellows, true chuck, ±10º swivel head, coolant system

...more

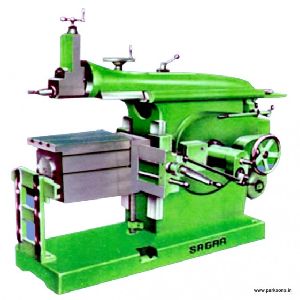

Shaping Machine

Description: Heavy Duty All Geared Shaping Machine The table can move ±600 The tool head also swivels ±600 The casting of the column, ram, cross slide and table are of high grade C.I. Specifications: (In mm unless specified otherwise) Accuracy: As per IS Standard 2310 Parallelism of the guide for the table support to traverse movement of table is 0.03mm/300mm Working accuracy of the machine parallelism of 0.03mm/300mm Application: Shaping of Grooves, Slots, Steps and Keyways Shaping inclined surfaces, beveled surfaces, dovetails Cutting of splines and gear teeth Irregular cutting and contour shaping Accessories: Auto tool lifting, Auto down feed, Keyway cutting attachment, Hydro-copying attachment

...more

Roll Turning Lathe

Description: All Geared Heavy-Duty Roll Turning Lathe Specialists in customizing roll turning lathes Machine is hand-scrapped for high accuracy and perfectly balanced to handle large rolls of 25-30 metric tons Graded Casting with flame hardened Guide ways Specifications: (In mm unless specified otherwise) Bigger main motor and large bore sizes available, if required Machines up to 1,000 mm Center Height and 10,000 mm Distance Between Centers available Accuracy: As per IS Standard 1878 (Part-II) / (Part- III) 0.02mm/800mm (diameter), taper of roundness and 0.03mm/300mm (length), for turning job when work piece is held on chuck/ through bore 0.025mm/300mm (diameter), concave of flat surface for facing job when work piece is held between centers Applications: Across Iron & Steel, Metals industries to re-grind roll mills Roll turning operations in Sugar, Paper, Cement, Power and Heavy Engineering industries Useful in plastic and metal die-making Accessories:Double Slotted Chuck, Grinding Attachment, Roller Steady Rest, Motorized Cross Slide, Taper Turning Attachment, Revolving Tailstock with inbuilt Chuck, Coolant System

...more

Radial Drilling Machine

Description: Heavy Duty Radial Drilling Machine Large base plate with broad column to withstand heavy load Column sleeve carrying arm rotates on ball bearing at top & bearing rollers at bottom Spindle is made of alloy steel. It moves on taper roller bearing Auto Feed 0.115 mm/rev is standard. Six Feed Range of 0.12- 1.2 mm/rev is optional Optional: Spindle Speed of 50-1600 RPM with Dual Speed Motor Accuracy: As per IS Standard 2199 Movement of drilling head parallel to base plate 0.015mm/ 1000mm of traverse True running of taper in spindle at top position 0.015mm Application: Machining of large components in Workshops and Fabrication Shops Drilling, Tapping, Counter Boring, Reaming, Screwing, Thread Cutting and Counter Sinking Suitable for Steel, Cast Iron, Alloy Steel, Stainless Steel, Medium Carbon Steel, Non-Ferrous Material Accessories:Box Table, Drill Vice, Machine Vice, Coolant System, Tapping Attachment

...more

Precision Centre Lathe

Description: All Geared Precision Centre Lathe Graded Casting with Hardened & Ground Guide ways Hardened & Ground Spindle and Gears in Headstock Induction hardened & Toughened Gears in Feedbox American Nose Spindle is standard and Cam lock Spindle Nose is optional Double screw apron totally enclosed in oil bath with overload tripping arrangement Accuracy: As per IS Standard 1878 (Part-I) Work piece on Chuck (Turning)-Roundness of 0.01mm taper near headstock Work piece between Centers (Facing) Flatness of 0.02mm/ 300mm length in concave direction Applications: Provides high precision machining for turning, facing, drilling, taper turning & boring operations Useful in laboratories, sample making, R&D divisions and tool making Accessories: Self Centering Chuck, Independent Jaws Chuck, Steady Rest, Follow Rest, Revolving Center, Gap Bed, Digital Read Out, Taper Turning Attachment, Grinding Attachment, Electromagnetic Footbrake, Milling Attachment

...more

Power Press Machine

Description: Steel construction frame, fabricated from rolled steel plates with suitable cross ribbings. This reduces vibration under heavy load. Crank shaft is made of special alloy steel machined to closed accuracy and fitted in bronze bushes for smooth working, longer life and accuracy. The gears are steel fabricated. The high grade C.I. flywheel stores and releases sufficient power for pressing operation. The heavy duty table and ram are also made of high grade C.I. They are perfectly aligned to obtain high precision pressing output. The lubrication system allows smooth sliding surfaces and moving parts to increase the lifespan of the machine Specifications: (In mm unless specified otherwise) Accuracy: As per IS Standard 8711 Application: Cutting, Bending, Punching, Embossing Accessories:Inclination Arrangement

...more

Power Hacksaw Machine

Hydraulic movement of cutting arm, The arm lifts out of contact of the work piece in the forward stroke to prevent damage to the blade or work piece, Three speed cutting feed controlled by a lever allows to adjust speed according to the material,Auto lift of cutting arm after job completion.

...more

Plate Bending Machine

Description: Pyramid type three roll plate bending and rolling machine Hydro-Mechanical operation with Fixed Bottom Rolls and Top Roll rotating by hydraulic system Electric Motor Brake and Independent Control Panel allows user to stop the machine at any point, thus allowing any shape in rolling Double gear box design (worm and spur reduction), prevents fatigue in motion and overload of motor even if the machine is bending at over capacity Housing is made from M.S. Plate of suitable strength and mounted on heavy base frame; Rolls are made from forged steel and perfectly machined for accurate result. Accuracy: As per IS Standard 14878 Applications: Fabrication of Pipes, Tanks, Pressure Vessels, Shipping Industry and Chimneys Cylindrical, Right Angle and Conical Bending Accessories:Pre-bending, Conical Bending, Digital Readout, PLC Controller

...more

Plano Miller Machine

Specialists in customizing Plano Miller machines The machine bed is of box type casting with vibration free construction,The table is driven by Rack & Pinion. It has T-slots for clamping work pieces,Auto lubrication is provided for table and cross slide,Motorized vertical movement of cross slide.

...more

Plano Miller Machine

Description: Heavy Duty Plano Miller Specialists in customizing Plano Miller machines The machine bed is of box type casting with vibration free construction The table is driven by Rack & Pinion. It has T-slots for clamping work pieces Auto lubrication is provided for table and cross slide Motorized vertical movement of cross slide Milling Head swivels ±45º for versatile operations AC Drive with Centralized Electric Control Panel Accuracy: As per IS Standard 2877Parallelism of top surface of work piece to bearing surface by horizontal feed of rail head: 0.02mm/2000m length of work piece (lengthwise) 0.03mm/2000mm length of work piece (crosswise) Application: First operation for horizontal, vertical and angular surfaces Edge Milling of plates in V, Double-V, J Grooving, Double-J, Beveling & Square Edge Grinding & Milling large components Accessories:Grinding Attachment, Second Milling Head on Cross Slide, Side Milling Head, Universal Milling Head with 360º movement

...more

Pillar Drilling Machine

Description: Machines are made of High Grade Casting– FG 260, IS 210 Spindles are Steel-Case, Hardened & Ground, making them very durable Heavy weight machines which are highly vibration resistant even at peak loads Components made on CNC machines, giving high accuracy and easy part interchangeability Specifications: (In mm unless specified otherwise) Bigger motor available on request Accuracy: As per IS Standard 2425 Applications: High speed drilling and tapping Precision thread cutting & screw cutting Suitable for Steel, Cast Iron, Alloy Steel, Stainless Steel, Medium Carbon Steel, Non-Ferrous Material Accessories: Drill Chuck, Drill Vice, Coolant System, Tapping Attachment

...more

Pedestal Grinder

Description: Double Ended Pedestal Grinder Double Ended Pedestal Grinder (1 Fine + 1 Coarse) Adjustable tool rests are provided to ensure maximum usage of grinding wheels Ball bearings are provided for vibration-free performance Dynamically balanced stamping and die cast rotor minimizes vibrations and ensures smooth running Safety features such as wheel guard, adjustable tool rest (to prevent the tool from getting stuck between the wheel and rest) and wheel guard are provided as standard supply Specifications: (In mm unless specified otherwise) Accuracy: As per IS Standard 2538 True Run Out of Spindle Taper: 0.05 mm Axial slip of spindle: 0.1 mm Applications: Forging Industries, Foundries and for heavy duty grinding jobs Grinding and sharpening cutting tools Can be used for dry as well as wet (optional) grinding Accessories:Twist drill grinding attachment, coolant system, dust exhaust equipment

...more

Milling Head Planer Machine

Description: All geared Milling Head, made of high grade stress-relieved C.I. Change gear system provides a 6 step spindle speed range and reduces the weight of the head Since changing of the cutter is not frequent in a Plano miller (unlike a milling machine), it is convenient to change the spindle speed through change gear pairs Spindle is provided with P5 Class Taper Roller Bearings (Total 4) + 1 Cylindrical Roller Bearing for rigid support Drive though ground splines in the spindle Gears, spindle, quill etc made of case hardening steel Case hardened & ground helical bull gear and mating gears for high torque transmission Spindle bearings lubricated for life with molybdenum sulphide grease Self contained, cam operated automatic lubrication system for gear box Accuracy: Spindle run-out on face, inner & out diameter: 0.01 mm Application: Increasing productivity by conversion of Planer to Plano miller. Single point tool cutting can be replaced by high speed, multi-point cutting by carbide cutters Cutting load is taken over by Milling Head reducing the load and speed of the table, thereby improving productivity and increasing machine life Accessories:Fixed Back Plate, Tilting Back Plate ±45º Right angle attachment: In combination with cross feed and vertical feed, adds floor boring capabilities to your converted Plano miller. The right angle attachment can be set to any angle ±360° allowing the user to machine all 4 sides of a rectangular job in the same setting

...more

Large Hydraulic Surface Grinder

Machine made of high grade C.I. with vibration absorbing quality and critical parts stress relived The Longitudinal and Cross Slides have high precision steel balls in guide ways for rendering highly smooth operation of the table. The alloy steel guideways are precision ground and hardened after heat treatment with anti-corrosion capability The wheel head is mounted on a pillar that slides in the column with utmost precision on Needle Roller Bearings and Ball Bearings. The spring loaded spindle runs in super precision angular contact preloaded anti-friction oil bathed bearings with optimum concentricity and balance characteristics Vertical movement of Wheel head is driven by independent motor. Least Count 0.001 mm Cross feed is infinitely variable 0.5- 10 mm/stroke. Least Count 0.001 mm Accuracy: As per Grade-I limits of Dr. G. Schlesinger’s Acceptance Test Grinding flatness in X & Y direction: 0.01mm/ 1000mm Application: Surface of Engine Blocks, Gears, Washers, Machine Frames, Valve Plates, Saw Blades, Blanks Clutch, Piston Rings, Connecting Rods, Crankshafts, Fuel Injection Components Accessories:Electromagnetic Chuck, Coolant System, Wheel Balancing Stand, Dust Collector, Universal 3-way Vice, Radius Truing Device, Wheel Dresser, Sine Table, Digital Readout

...more

Hydraulic Surface Grinding Machine

1,200,000 Per Piece

Driven Type : Hydrualic

Material : Cast Iron

Hydraulic Surface Grinder

Description: Hydraulic High Precision Surface Grinder Machine made of high grade C.I. with vibration absorbing quality and critical parts stress relived Vertical Feed Screw & Cross Screw are hardened & ground For friction free movement on ‘X’ & ‘Y’ axes, ‘V’ & ‘Flat’ of fixed slide is coated with Turcite Spindle runs with multiple RHP super precision P7 grade bearings, grease packed for life. This provides highly precision movement i.e. zero end float & zero radial play. Vertical movement of Wheel head is driven by independent motor. Least Count 0.002 mm Cross feed is infinitely variable 0.3- 6 mm/stroke. Least Count 0.01 mm Machine is equipped with Electro-magnetic chuck, Hydraulic System with independent motor, motorized coolant system, centralized lubrication, wheel balancing stand Specifications: (In mm unless specified otherwise) Higher table speed up to 18 M/min available on request Accuracy: As per IS Standard 2743 Parallelism of table movement to Surface of Magnetic Table (X-Axis): 0.015/ 460 mm Parallelism of table movement to Surface of Magnetic Table (Y-Axis): 0.01/ 200 mm Application: Surface of Engine Blocks, Gears, Washers, Machine Frames, Valve Plates, Saw Blades, Blanks Clutch, Piston Rings, Connecting Rods, Crankshafts, Fuel Injection Components Accessories:Dust Collector, Universal 3-way Vice, Radius Truing Device, Wheel Dresser, Sine Table, Digital Readout

...more

Hydraulic Press

Description: Hydraulic Motorized ‘H’ Frame Four Pillar Press All steel construction provides a sturdy frame for low vibration under heavy load Easy to operate. Machine can be stopped at any position. Safety valve to prevent overloading Adjustable table height for versatile operations The machine is equipped with Pressure Manometer and ‘V’ blocks Accuracy: As per IS Standard 14877 Perpendicularity between vertical movement of slide and upper surface of bolster: 0.4 mm Parallelism of lower face of slide with respect to the upper face of bolster: 0.8 mm Applications: Straightening bent fabricated bodies or sheets General Purpose Press for Repair Workshops Pressing of Ball Bearings Removal of Old Bushes And Mounting New Bushes

...moreBe first to Rate

Rate This