stainless steel pickling

Get Price Quote

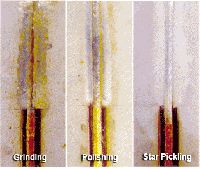

Pickling and Passivation process ensures corrosion resistance and removes free ion contamination left on the SS surface from fabricating and machinery. These contaminants are prospective corrosion sites resulting in premature corrosion, ultimately resulting in decline of component if not removed. Corrosion resistance of SS is because of the presence of 13 percent chromium in alloy. The chromium, with oxygen, forms a think chemically resistant passive layer of chromic oxide thus shielding the SS surface against corrosion. The passive layer generally forms again after abrasion. All mechanical treatments damage the topmost layer of components i.e.Structural modifications in top layers of SS,Development of in-built stress

pickling service

Get Price Quote

Pickling is carried out on various grades of Stainless Steel substrates to remove impurities & surface contamination on the surface resulting from various fabrication activities carried out on the stainless steel surfaces. We have dedicated & experienced team to carry out the process by taking customer requirements into consideration

Looking for Pickling Service Providers

Pickling & Passivation On Stainless Steel

Get Price Quote

Pickling & Passivation On Stainless Steel, electropolishing, Pickling Tank

Steel Industries Pickling Line Service

Get Price Quote

Steel Industries Pickling Line Service, Cashew Nut Shell Liquid

Stainless Steel Pipe Pickling Services

Get Price Quote

Stainless Steel Pipe Pickling Services

Pickling Services

Get Price Quote

Pickling Services