DUPLEX STEEL 31803 PLUG

148 Per Piece

1 Piece(s) (MOQ)

Threaded Hex Head Plug

Get Price Quote

Threaded joints probably represent the oldest method of joining piping systems. Threaded fittings are mainly used for small pipe diameters (Small Bore Piping); generally for piping whose nominal diameter is NPS 2 or smaller. Threaded piping is commonly used in low-cost, noncritical application such as domestic water, fire protection and industrial cooling water systems. DIAMENTION . STD :- ASME B16.11. GRADE :- ASTM/ASME A105, A350 LF2 & A182 Gr.F5,F11,F22,F51,F52,F91,F92,F 304, F304H,F304L,309S, 309H, F310,F316, F316L,F317, F317L,F321 & F347H CLASS :- 3000#, 6000# & 9000# THREADED TYPE :- NPT, BSP & BSPT RANGES :- 1/2”NB TO 4”NB SPECIAL GRADE :- Titanium Steel, Hastelloy Steel, Duplex Steel, Super Duplex Steel, Monel Steel, Incoloy Steel, High Nickel Steel, Cupper-Nickel Alloys SMO-254, Cupper, Brass, etc. in all Grades

Best Deals from Pipe Plug

Head Plug

Get Price Quote

We are offering head plug material type: stainless steel, alloy steel and carbon steel nickel alloy astm asme sb 336 uns 2200 ( nickel 200 ), uns 2201 (nickel 201 ), uns 4400 (monel 400 ), uns 8020 ( alloy 20 20 cb 3, uns 8825 inconel (825), uns 6600 (inconel 600 ), uns 6601 ( inconel 601 ), uns 6625 (inconel 625), uns 10276 ( hastelloy c 276 ) stainless steel astm asme sa 403 gr wp "s" "w" " wx" 304 , 304l, 304h, 304n, 304ln, 309, 310h, 316, 316h, 317, 317l, 321, 321h, 347, 347 h. duplex steel astm asme sa 815 uns no.s 31803, s 32205, s 32550, s 32750, s 32760. carbon steel astm asme a 234 wpb, wpc astm asme a 860 wphy 42, wphy 46, wphy 52, wph 60, wphy 65 & wphy 70. alloy steel astm asme a 234 wp 1, wp 5, wp 9, wp 11, wp 12, wp 22, wp 23, wp 91.

Forged Plug

Get Price Quote

100 Piece (MOQ)

Ferrule Pipe Male Plug

Get Price Quote

We are prime Supplier of Ferrule Pipe Male Plug from Maharashtra, India. These plugs are manufactured as per international quality standards and widely used for pipe fitting in various industries. The product comes with a fine finish, compact size and completely checked prior to dispatch. We maintain a large stock of the Ferrule Pipe Male Plug to meet the urgent requirements of the buyers. Details : Available size – 1/8’’ to 1’’ Compact and easy to install Negligible maintenance Finest quality raw material used with corrosion resistance

copper plug

Get Price Quote

100 Kilogram (MOQ)

Carbon Steel Plugs

Get Price Quote

200 Piece (MOQ)

Screwed Forged Plug

Get Price Quote

10 Piece (MOQ)

Threaded Bull Plug

Get Price Quote

Audco Cast Iron Plug Valve

1,500 Per Piece

5 Piece (MOQ)

Stainless Steel Square Plug

Get Price Quote

100 Piece (MOQ)

Alloy Steel Square Plug

Get Price Quote

We are offering alloy steel square plug. Our clients can avail a quality range of alloy steel square plug through us in market leading prices. The teams of engineers in our company are skilled enough to design the best quality square plug that can satisfy the requirement of our clients. Designed using the latest techniques and premium quality raw material these square plug is highly demanded among our clients for its quality features like high tensile strength and reliability. Features: • reasonable rates. • durability • reliability • high mechanical strength. • resistive against degradation. • resistive against corrosion and rust. Material: • alloy steel square plug – as square plug standards: a182 f5 square plug a182 f9 square plug a182 f11 square plug a182 f22 square plug a182 f91 square plug

Aluminium Drain Testing Plug

Get Price Quote

10 Metric Ton (MOQ)

Duplex Steel Plug

250 Per unit

Titanium Forged Fittings plug

Get Price Quote

Metal king exports a wide range of titanium forged fittings plugs (fitting) made of exotic metals, nickel, cupro-nickel, stainless steel etc., of various dimensions and grades such as gr.2, gr.5, gr.7, gr.9, gr.12,and special grades like gr.23 as per requirement of clients’. Metal king supplies high quality plug that can be used for various applications and are available in a variety of style and sizes. Plugs(fitting) are designed to provide a quick and simple means to perform a variety of jobs such as stopping flow in a pipeline (for maintenance or repair), down stream pipeline acceptance testing, or to stop flow so that infiltration of a section can be measured etc.

Pipe Plug

Get Price Quote

Carbon Steel Plug

Get Price Quote

With the rich industry experience in the respective domain, we are offering our clients a quality range of carbon steel plug. Available in various sizes, shapes and specifications these are mainly used to close the end of the pipes. Made carbon steel ie, these carbon steel plug are similar to cap but fitted inside the fittings. Further, also provide customization facility and offer these plugs as per the requirement of our clients. Size : 12"nb to 4"nb in class : 3000 lbs, 6000 lbs, 9000 lbs type : socket weld (sw) & screwed (scrd) – npt, bsp, bspt form : hex plug, square plug.

Stainless Steel Head Plug

190 Per Piece

1 Piece(s) (MOQ)

We are known for delivering the orders within the specified time frame owing to our modern transit facilities. We have automated systems to manage the sorting and packaging of all the products that are kept in the spacious warehouse. To look after this, we have hired veteran professionals. We deal in Stainless Steel Head Plug is available in different sizes and designs along with a good packaging.

Forged Hexagon Plug

Get Price Quote

Forged Plug, Socket Weld BS3799 Forged Plug, ASME B16.11 Forged Plug, Threaded Forged Plug, Manufacturer and Exporter in India. Stainless Steel Forged Plug, Carbon steel Forged Plug, Alloy Steel Forged Plug, Aluminum Forged Plug, Titanium Forged Plug supplier.Shasan Piping Solution is one of the surely understood associations in Manufacturers, Supplier and Exporters of the High Standard Quality of Forged Plug in funnel fittings. They are accessible in a wide range of Threaded Plug like Bull Plug, Hex Head Plug, Round Head Plug, Square Head Plug, etc. These Threaded Plugs are broadly utilized as a part of various application commercial ventures, for example, oil refineries, petrochemical, substance handling, bond industry, et cetera. They are very easy to introduce the channel plugs for the allotment of funneling frameworks completely through repair, testing or upkeep of the gouged channel lines.Details : Standard - ANSI/ASME, MSS, JIS, DIN, BS etc RANGE - Forged Fittings 15 NB to 100 NB in 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS available with NACE MR 01-75. TYPE - Socket Weld (S/W) & Screwed (SCRD) – NPT, BSP, BSPT Stainless Steel Standard - ASTM / ASME A/SA 182 Grade - F 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L Carbon Steel Standard - ASTMA 105/A694/ A350 LF3/A350 LF2. Grade - F42/46/52/56/60/65/70 Low Temperature Carbon Steel ASTM A 350 LF2 / A350 LF3 Alloy Steel Standard :ASTM A182 Grade - F1/F5/F9/F11/F22/F91 Duplex Steel Standard - ASTM / ASME A/SA 182 Grade - F 44, F 45, F51, F 53, F 55, F 60, F 61 Copper Alloy Standard - ASTM / ASME SB 61 / 62 / 151 / 152. Grade - UNS NO. C 70600 (CU -NI- 90/10), C 71500 (CU -NI- 70/30) C 71640 Carbon Steel Standard - ASTM A 105/A694/ A350 LF3/A350 LF2. Grade - F42/46/52/56/60/65/70 Low Temperature Carbon Steel ASTM A 350 LF2 / A350 LF3 Alloy Steel Standard - ASTM A182 Grade: F1/F5/F9/F11/F22/F91 Forms - Elbow 45 deg , 90 degree & Three way elbow Nickel Alloy Standard : ASTM / ASME SB 564 / 160 / 472 Nickel 200 Fittings – UNS N02200 Nickel 201 Fittings – UNS N02201 Monel 400 Fittings – UNS N04400 Monel K500 Fittings – UNS N05500 Inconel K600 Fittings – UNS N06600 Inconel 601 Fittings – UNS N06601 Inconel 625 Fittings – UNS N06625 Inconel 800 Fittings – UNS N08800 Inconel 800H Fittings – UNS N08810 Inconel 825 Fittings – UNS N08825 Hastelloy C276 Fittings – UNS N10276 Alloy 20 Fittings – UNS N08020

BSPT Pipe Plugs

100 Per Piece

10 Piece (MOQ)

Titanium Plug

350 Per Piece

50 Piece (MOQ)

Stainless Steel Forged Plug

Get Price Quote

1 Ton (MOQ)

Pipe Plug

50 - 1,000 Per piece

50 Piece (MOQ)

GRADE: AVAILABLE. Carbon Steel: ASTM A105/ A105N/ A694 F42/46/52/56/60/65/70 / A350 LF3/ A350 LF2, etc. Alloy Steel: ASTM A182 F1/ F5/ F9/ F11/ F22/ F91/ etc. Stainless Steel: ASTM A182 F304/ 304L/ 304H/ 316/ 316L/ 317/ 317L/ 321/ 310/ 347/904L/ etc. Duplex steel : UNS S3180,UNS S32205(2205), UNS S32750(32750) , UNS S32760(ZERON 100) Nickel: UNS N02200, UNS N0220 Inconel : UNS N06600, UNS N06625 , UNS N08800 , UNS N08810, UNS N08811, UNS N08825 Monel: UNS N04400, UNSN05500 Hastelloy : UNS N10276, UNS N06022, UNS N10665 Alloy 20: UNS N08020 Copper Nickel: UNS C70600(90:10), UNS C71500(70:30) Titanium : GR.1 R56250(CP4), GR.2 R50400(CP3), GR.3 50550(CP2), GR.4 50700(CP1), GR R56400(6AI-4V) , GR.7 52400, GR.1 R52250, GR.23 R56401

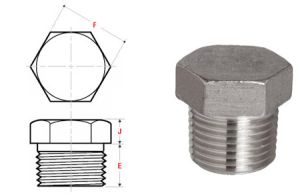

ASME B16.11 Threaded Hex Head Plug

100 - 200 Per Piece

100 Piece (MOQ)

Material and Grades: Carbon Steel: ASTM A234 Gr. WPB ASTM A420 Gr. WPL6 ASTM A105 ASTM A350 Gr. LF2 Stainless Steel: ASTM A403 WP316/316L ASTM A403 WP304/304L ASTM A182 F316L, 304L Packaging: ASME B16.11 Threaded Hex Head Plug Flanges is sleeved into plastic bag individually, ten pieces wrapped with water-proof material, bundled with nylon rope. Clear labels are tagged on the outside of the package for easy identification of the quantity and product I.D. Great care is taken during operation and transportation. Prevent any damage. During transportation items are tagged, packed in plastic bags and closed in carton boxes or seaworthy wooden cases. plywood case,pallet and according to customer's requirment Marking: ASME B16.9 Threaded Hex Head Plug Flanges are marked with alloy name, outside diameter, wall thickness and heat number. Additional information like standard and alloy numbers can be added on request.

Head Plug

50 Per Piece

100 Piece (MOQ)

Carbon Steel Plugs

55 Per Piece

5 Piece (MOQ)

Stainless Steel Pipe Plug

Get Price Quote

With features like superior quality and unmatched grade, our product range is the best one available in Mumbai(India). Our payment procedures are hassle free and transparent. We take aid of reliable online and offline payment procedures for your safety as well as ours. We ensure the payment is done legally along with documentation. Features : High strength Corrosion resistance Durability Dimensionally accurate

threaded plug

Get Price Quote

8 Piece (MOQ)

Stainless Forged Threaded Plugs:ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F904L, ASTM A312/A403 TP304, TP304L, TP316, TP316LAlloy Steel Forged Threaded Plugs:ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91Carbon Steel Forged Threaded Plugs:ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR.A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & CDuplex & Super Duplex Steel Forged Threaded Plugs:ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.Nickel Alloy Forged Threaded Plugs:ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200), UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400), UNS 8020 (ALLOY 20 / 20 CB3), UNS 8825 (INCONEL 825), UNS 6600 (INCONEL 600), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276).Copper Alloy Steel Forged Threaded Plugs:ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 (CU -NI- 90/10), C 71500 (CU -NI- 70/30)

Forged Plug Fitting

Get Price Quote

M-Pipe & Fitting Solution Inc is a reputable company that manufactures and supplies high-quality forged plug fitting. Forged Plug Fitting are essential components used in piping systems to close off the ends of pipes, fittings, or valves. They provide a secure and leak-proof seal, preventing the flow of fluids or gases. Forged plugs are manufactured through a forging process, which involves shaping and forming metal using heat and pressure. Carbon Steel Forged Fittings Plug (ASTM A105) and ASTM A182 F51 Forged Plug. We will discuss their features, applications, and advantages in piping systems. Carbon Steel Forged Fittings Plug (ASTM A105): ASTM A105 is a typical specification for carbon steel forgings used in high-temperature and high-pressure applications. Carbon steel forged fittings plugs made from ASTM A105 offer several advantages: Material Properties: ASTM A105 carbon steel offers excellent strength, flexibility, and impact resistance. It is suitable for a wide range of applications requiring high mechanical strength. Corrosion Resistance: Carbon steel forged fittings plugs made from ASTM A105 are resistant to rust and oxidation. However, they are not recommended in corrosive environments or applications involving exposure to acids or highly corrosive substances. Pressure and Temperature Ratings: ASTM A105 forged fittings plugs are designed to withstand high-pressure and high-temperature conditions. They are suitable for applications in oil and gas, petrochemical, power generation, and more industries. Size Range: Carbon steel forged fittings plugs made from ASTM A105 are available in various sizes, typically specified by the nominal pipe size (NPS) and the pressure class or schedule. Versatility: Carbon steel forged fittings plugs can be used in a wide range of applications, including both threaded and socket weld connections. They are commonly used to close off the ends of pipes, valves, and fittings during maintenance or when a section of the system is not in use. ASTM A182 F51 Forged Plug: ASTM A182 F51 is a duplex stainless steel grade that offers a combination of excellent corrosion resistance and high strength. Forged fittings plugs made from ASTM A182 F51 have the following characteristics: Corrosion Resistance: ASTM A182 F51 forged plugs resist various corrosive environments, including chloride-containing solutions, acids, and seawater. It makes them suitable for applications in chemical processing, offshore, and marine industries. High Strength: ASTM A182 F51 duplex stainless steel offers high mechanical strength, allowing the forged plugs to withstand high-pressure and high-stress conditions. Size Range: ASTM A182 F51 forged plugs are available in various sizes, typically specified by the nominal pipe size (NPS) and the pressure class or schedule. Temperature Range: ASTM A182 F51 forged plugs exhibit good mechanical properties over a wide temperature range, making them suitable for low and high temperatures applications. Resistance to Stress Corrosion Cracking: ASTM A182 F51 duplex stainless steel has excellent resistance to stress corrosion cracking, a common concern in corrosive environments. It makes it suitable for applications where the forged plug is simultaneously exposed to tensile stress and corrosive substances. Plug Fittings: Plug fittings, including forged fittings plugs, play a crucial role in piping systems by providing a secure and leak-proof seal. Some key points about plug fittings include: Types: Plug fittings are available in various types, including hex and square head plugs. Hex plugs have a hexagonal head, allowing for easy installation and removal using a wrench. Square head plugs have a square-shaped head, providing a larger contact surface for tightening and loosening. Threaded and Socket Weld Connections: Plug fittings can be designed with threaded or socket-weld connections. Threaded plugs have internal threads that match the external threads of the pipe or fitting, allowing for a secure connection. Socket weld plugs have a socket-like structure that fits over the pipe end and is welded in place. Installation and Removal: Installing a plug fitting involves threading it into the corresponding threaded opening or welding it in the case of socket weld connections. Proper installation techniques, such as applying thread sealant or using the correct welding procedures, should be followed to ensure a tight and leak-free connection. Removal typically requires the use of wrenches or other appropriate tools. Applications: Plug fittings are used in various applications across different industries. They are commonly employed in oil and gas pipelines, chemical processing plants, refineries, power generation facilities, and other systems where temporary or permanent closure of pipe ends or fittings is required. Advantages of Forged Fitting Plugs: Secure and Leak-Proof Seal: Forged fitting plugs provide a reliable and leak-proof seal when properly installed. It helps maintain the integrity of the piping system, preventing fluid or gas leakage and minimizing the risk of accidents or environmental damage. Strength and Durability: Forged plugs, whether made from carbon steel or duplex stainless steel, offer excellent strength and durability. They can withstand high-pressure and high-temperature conditions, ensuring long-term performance and reliability. Corrosion Resistance: The choice of material, such as ASTM A105 carbon steel or ASTM A182 F51 duplex stainless steel, provides varying degrees of corrosion resistance. It allows forged fitting plugs to be used in a wide range of corrosive environments, enhancing the longevity of the piping system. Versatility: Plug fittings are versatile components in different connections, including threaded and socket weld. They can be easily installed, removed, and reinstalled as needed, making them suitable for temporary and permanent closure applications. Compatibility and Standardization: Forged fitting plugs are designed and manufactured to adhere to industry standards and specifications, ensuring compatibility and interchangeability with other components. It simplifies installation, maintenance, and replacement procedures. Forged fitting plugs, made from carbon steel or duplex stainless steel, are essential components in piping systems. They provide a secure and leak-proof seal, ensuring the system’s integrity. The choice of material depends on the application’s specific requirements, including corrosion resistance, pressure, temperature ratings, and the environment in which the plug will be used. Proper installation techniques and adherence to industry standards are crucial for ensuring optimal performance and safety of the piping system. M-Pipe & Fitting Solution Inc provides certified forged fitting that meet international standards such as API, ASTM, and ISO 9001:2015.

Mild Steel Hex Head Plug

Get Price Quote

1 Metric Ton (MOQ)