Planetary mixer

Get Price Quote

We are offering planetary mixer

Stainless Steel Planetary Mixer

Get Price Quote

Best Deals from Planetary Mixer

Planetary mixer

Get Price Quote

The Planetary mixer machine is basically mixing assembly wherein the agitation pattern is of a planetary nature. If offers optimum output as these are installed with gearbox, variable speeds with electronic control. Further, our range can be customized as required by our clients. The blade movement and up-down movement is done through hydraulic system, so that electrical contact is avoided. CCTV is provided to see the operation in remote working PLC along with SCADA operates the full system from a safe distance.For the processing of sensitive & hazardous heterogeneous compositions containing low to medium viscosity resins/binders & various dried particulate fillers having different particle size ( less than 1 micron to 300 micron) under high vacuum. Intimate mixing of these ingredients is must to ensure uniform mix. End of Mix viscosity to these compositions may vary from 50 poises to 80000 poises at 25°C. For removal of moisture & occluded gas / air from high viscosity composition, application of high vacuum of 0.1 mm of Hg is necessary during mixing. For very viscous compositions initial circulation of hot water through mixer jacket is essential and to avoid sudden rise in viscosity after addition of curing agents cold water circulation through jacket is required. The Planetary mixer unit consist of a Mixer, bowl with trolley, hydraulic drive unit, remotely operated control system with PLC & SCADA along with power back up system for PLC & close circuit camera & color Monitor for remote viewing, during Mixer Operation.We offer wide range of planetary mixers for Defense industry which are manufactured in different specifications and capacities. With excellent deaeration, these planetary mixers prevent the paste from becoming lumpy. With robust construction and durability, these planetary mixers are widely used for mixing, degassing and kneading viscous and heat sensitive pastes. We also offer tailor made requirements. The speed of planetary mixers ranges from 1rpm to 100 rpm. We can obtain products containing solids Upto 85% in the final mixture.Material of Construction (MOC) Offered : - CS (IS 2062 Gr A/B, SA 516 Gr 60/70, BQ), SS 316, SS 304, SS 316 L, SS 304 L. SS 310, MONEL, INCONEL, TITANIUM, HASTALLOY, ETC.

Planetary mixer

Get Price Quote

Planetary Mixer Planetary mixers are an ideal mixer for the products of different viscosities, densities, shapes & proportions. The major uses include the production of latexes, dispersion & micro — dispersion of Chemicals, Explosive & agricultural pesticide formulations. It is suitable for mixing / blending powders as well as through mixing of ointments, creams, lotions, toothpastes, resins, Slurries, ceramics, colors, pigments, rubber & other compounds. Planetary mixers consist of a single r double blade with a high speed dispersion blade (Emulsifier / Homogenizer) Intimate & homogeneous mixing of products is achieved by planetary motion of beaters & centrally located high speed dispersion blade for vacuum jacketed mixer units. They are used in many process operations Ike Homogenization, Dispersion, Emulsification, Grinding , Dissolving, Chemical reaction, Cell disruption & Coagulation Capacity - 3 to 2500 liters

40 Liter Planetary Mixer

108,000 Per Piece

3 Piece (MOQ)

Planetary mixer

Get Price Quote

Standard Models are available in 100 litres to 600 litres Planetary motion of the mixing beater gives intimate and homogenous mixing of the various ingredients Standard Mixer consists of single mixing beater which rotates in planetary motion i.e., clock wise direction about the central axis and anti clock wise direction about its own axis Hydraulic/Motorized lifting and lowering arrangement can be provided Product bowl is mounted on caster wheels for easy portability for washing and transporting the material The contact parts of these mixers are made up of SS 304 or SS 316 steel The mixing bowl can be jacketed for electric/steam/Thermic fluid heating The mixing bowl can be provided with P.U. Caster wheels and locking system for easy handling and transportation The mixer has double beaters open type that covers full cross section of product in bowl The top of the mixing bowl has SS Lid with a charging port Ideal equipment for small/medium batch sizes Full interlocked guarding Easy dismantling for the purpose of Cleaning and maintenance APPLICATIONS Planetary Mixers are used for homogenous mixing of ingredients of different densities in different proportion Solid / Solid, Liquid / Solid and Liquid / Liquid mixing is achieved effectively by the use of Planetary Mixer Vacuum Jacked Planetary Mixers are designed to achieve best results in preparation of ointment, toothpaste, creams and suspensions

Planetary Mixers

Get Price Quote

Description We are instrumental in manufacturing and exporting ofPlanetary Mixer, which is manufactured from quality materials and using cutting-edge technology. These Planetary Mixers has schematic arrangement of mixing action, which is based on high shear blade agitator system. We offer Planetary Mixer in varied specifications in order to meet clients requirement. We, Becky Consultancy Services, are a well-recognized manufacturer, supplier and exporter of highly efficient Planetary Mixer. This mixer is manufactured by utilizing superior grade electronic and electrical components. Also, proper testing and inspections are carried out before sending the product to our clients. The robust construction of the mixer assures its longer functional life and zero-defect output. Our Planetary Mixer has minimal maintenance needs and finds varied applications in various industries for mixing of ointments, shaving creams, liquids etc. Features Optimum Mixing Performance Minimal Maintenance Needs Less Power Consumption Longer Service Life Sturdy construction High performance Optimum quality Durability Used in the mixing of Bakery Products Shaving Cream Toothpaste , etc.

Planetary mixer

Get Price Quote

Planetary Mixer is ideal for mixing of wet / dry materials. It has a homogeneous mixing action. The planetary motion of the beater enables faster and better mixing of material at a considerably lesser time. Slow speed is used for dry mixing with less dust generation and faster speed for kneading operation during wet granulation portable mixing bowl with top mounted agitator has a dual advantage of material transfer and no risk of gland packing contamination.

Planetary Mixers

Get Price Quote

We are offering planetary mixers. • planetary mixer has facilitated a wide range of operations from the production of vast quantities of products and handling simple mixtures to complex reactions, which involve high internal pressure and controlled temperatures. • we offer these in stirrer designs and generate orbital rotation, just like a beater covers every point of the bowl, to provide efficient mixing results. • planetary mixer has use for manufacturing of medicament, ointments, cosmetics: cold creams, hair dye cream, conditioners, lotions, gels, shampoo, and toothpaste etc. • planetary mixer has advanced drive heads that heads can be raised and lowered by using a manual, hydraulic or electro mechanical means. • the bowls are easily removable and facilitated the users in applications requiring remote discharge and cleaning. • the bowls are design for full vacuum or pressure. • the bowls are also providing jacketed bowls as an optional attachment depending on the heating and cooling requirements of the clients.

Planetary mixer

Get Price Quote

Intimate and homogenized mixing of products is employed by planetary motion of beaters and centrally located homogenizer. Equipment is ideally suitable for thorough mixing of ointments, creams, lotions, tooth paste etc. in sterile or non-sterile conditions. Product container provided with jacket to heat and cool for circulation of steam/cold water. Mixer is also designed to operate under vacuum to remove air entrapment in product during mixing . High speed disperser suitable for homogenizing the product with independent drive at the centre. Salient Features Product bowl mounted on castor wheels for easy portability, washing &transporting mixed materials. Jacketed bowls available for heating or cooling of products during mixing Provision to mix materials under vacuum for duration purpose. Double beater open type to cover full cross section of products in bowl. Scrapper of suitable design to avoid localized heating or cooling & ensure uniform mixing. Flameproof construction optional Motorized and Hydraulic drive assembly for lifting and lowering. Needs comparatively smaller area for installation. Contact parts in SS 316/SS316L. Higher capacities models 1000 L. to 1500 L. on request

Planetary mixer

120,000 Per Piece

Planetary mixer

Get Price Quote

Stainless Steel Planetary Mixer

33,000 Per Piece

Planetary mixer

Get Price Quote

This equipment is basically a mixing assembly where the agitation pattern is of the planetary nature The beater or the agitation assembly rotate around itself as well as travel in a circle in the bowl thereby achieving intimate mixing. Because of special design feature of shifting the mass is uniformly and intimately mixed.

Planetary mixer

58,000 Per Piece

1 Piece (MOQ)

Cake Mixer (Planetary Mixer)

Get Price Quote

- Planetary action with three speeds - 38, 128 and 170 RPM for perfect mixing. The agitator rotates on its axis in the opposite direction to the bowl. This lets the agitator reach every part of the batch for the most uniform mixing, thoroughly blending and aerating all the ingredients - Mixers supplied with a Stainless Steel bowl, Flat Beater and Wire Whip. A Dough Hook and a Bowl Truck can be supplied optionally at extra cost - All contact parts are made from Stainless Steel 304 - Gears are heat treated alloy steel and in mesh in a special lubricant assuring quiet operation and long life .

Planetary mixer

300,000 - 1,000,000 Per Piece

The planetary mixer is an industrial equipment conceived/made to prepare food, chemical, ceramic dough or other type of product, replacing manual labor through a mechanical system that allows to produce, continuously, large quantities of dough. Discription : Bowl for ingredients placement Mixing element (whisk, hook, flat beater, scrapper or other system) Motors that start the bowl and whisk movements Interconnection of technological process that allows to the operator the control of the mixing process and other labour process (programming times and speeds; mixing elements) The name “planetary mixer” comes from the system used in the equipment that mixes the dough in the planets rotation direction. The planetary mixers Ferneto are ideal to produce pastry products such as emulsions, creams, batters and other sophisticated desserts witch require larger, faster and powerful rotation movements. The range of the planetary mixers Ferneto include an extended equipment set of, suitable for small and large productive bakery and pastry units as well as other food units (catering, hospitality and similar industries). This equipments are available in standard, stainless steel and marine version. The main differences are based on: construction structure, raw material and esthetics features. Do you want home made products with the added value of a machine? Are you looking for an equipment that can assist you? Do you want productive performances keeping higher quality standards? Find out the planetary mixer and know how to improve the quality of your production.

Tabletop Planetary Mixer

Get Price Quote

PLANETARY MIXE

Get Price Quote

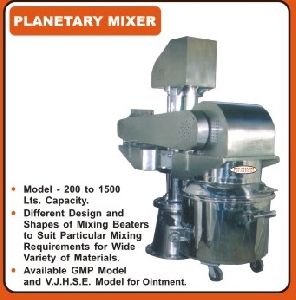

ntimate blending of different materials of different consistencies, viscosities, densities, shapes, proportion liquid / liquid,/ solid/solid is achieved effectively by use of planetary mixers. 1. Compact design of machine takes up minimum floor space. 2. Beater arms are available in a range of designs to achieve optimum out put for different types of materials. Special Features: Product bowl mounted on castor wheels for easy portability, washing and transporting mixed materials. Choice of different designs of beaters to suit particular mixing requirements for a wide variety of materials. Flameproof construction optional. Higher capacity 750 L and 1000L models with auxiliary beaters. Motorized drive assembly for lifting and lowering. Needs comparatively smaller area for installation. Electrical control panel with back up fuses and indicator lamps for easy process control. Contact parts of S.S. 316 quality material. S.S 304 construction optional. Proper selection of Planetary and beater RPMs for different products.

Planetary mixer

Get Price Quote

Planetary Mixer is basically a mixing assembly where the agitation pattern is of the planetary nature. Our Planetary Mixer has special design feature of shifting the mass that is uniformly and intimately mixed. Planetary mixer completes with S.S. removable bowl. The Planetary Mixer machine is provided with a hand drive worm gear arrangement to lift and lower the bowl and is complete with 1phase/3 phase 400/440 volts, 50 cycles electric motor. Clients can avail the Planetary Mixer from us at highly affordable price. About Planetary Mixer Available in all grade of carbon steel and stainless steel Optional Teflon coated internals for food and sticky material application Jacketed construction available for steam and cooling application Available in working capacities of 5 liter to 500 liter Mixing bowl is made portable to facilitate comfortable transporting , washing etc Various types of beaters can be provided for different materials Motorized , manual lifting and sliding arrangement possible for bowl Flame proof construction optional The beater or the agitation assembly rotate around itself as well as travel in a circle in the bowl thereby achieving intimate mixing Planetary mixer complete with S.S. removable bowl, S.S. blade having variable 3 different speeds and one neutral speed suitable for mixing and beating for viscous and pasty materials The machine is designed for practical and easy operation and running is noiseless very easy to operate with minimum of attention

Planetary mixer

152,600 - 697,000 Per per unit

1 piece (MOQ)

special features: * all contact parts s.s. 316 quality material * product bowl mounted on castor wheels for easy portability. washing & transporting mixed materials. * motorized drive assembly for lifting & lowering. * needs comparatively smaller area for installation. * electrical control panel with backup fuses and indicator lamps for easy process control of different products. we have model 10 lts to 1500 lts capacity

planetary mixer machine

Get Price Quote

SS 304 Planetary mixer complete with S.S. removable bowl, S.S. blade having variable 3 different speeds and one neutral speed suitable for mixing and beating for viscous and pasty materials. The machine is designed for practical and easy operation and running is noiseless very easy to operate with minimum of attention, the machine is provided with a hand drive worm gear arrangement to lift and lower the bowl and is complete with 3 phase 400/440 volts, 50 cycles electric motor.

Planetary mixer

Get Price Quote

We bring forth highly efficient Planetary Mixers for the global market. We are associated with the league of #1 Manufacturers, Exporters, and Suppliers of Planetary Mixers from Mumbai, India. These Mixers have varying speeds for mixing cream and eggs to prepare pastries and cookies. They come along with an array of accessories that includes S.S. bowl, one eggs whisk and beater. Buy them at reasonable prices from us!

Planetary Mixer 60 L

Get Price Quote

Planetary mixer

30,000 - 35,000 Per Piece

Planetary mixer

Get Price Quote

Planetary Mixers are used for dry mixing and dough mixing. The homogenous mixing af various lngredients of different densities in different proportions for solid/solid, liquid/solid, and liquld/Iiquid is achieved effectively by the use of Planetary Mixer. Vacuum Jacketed Planetary Mlxers for the preparatlan of aintment; toothpaste; creams; suspensions. are designed to achieve the best results. All contact parts are made from S S 304 or SS 316 steel as per client's requirements. Standard Mixer is available in 200, 350 and 600 Ltrs... capacities. The Planetary motion af the mixing beater ensures effective homogenous mixing of the various ingredients. Standard Mixer consists of single mixing beater which rotates in planetary motion i.e. clock wise direction about the central axis and anticlock wise direction about its own axis. The main drive, lifting and lowering operations is motorised. The product bowl is mounted on castar wheels for easy portability for washing and transporting the material. Vacuum Jacketed Mixer consists of two open beaters moving in planetary motion, scraper blade and centrally located high shear emulsifier run by a separate motor for Manufacturer of creams, ointments, suspensions etc.

planetary mixer machine

Get Price Quote

PLANETARY MIXER: This equipment is basically a mixing assembly where the agitation pattern is of the planetary nature The beater or the agitation assembly rotate around itself as well as travel in a circle in the bowl thereby achieving intimate mixing. Because of special design feature of shifting the mass is uniformly and intimately mixed. Planetary mixer complete with S.S. removable bowl, S.S. blade having variable 3 different speeds and one neutral speed suitable for mixing and beating for viscous and pasty materials. The machine is designed for practical and easy operation and running is noiseless very easy to operate with minimum of attention, the machine is provided with a hand drive worm gear arrangement to lift and lower the bowl and is complete with 1phase/3 phase 400/440 volts, 50 cycles electric motor Used for mixing of Ointments, dry powder or wet hard mass etc. All contact parts made out of SS. Capacity 20kg to 500kg. Optional: Unit with FLP motors and FLP push button station but non FLP panel to be mounted outside FLP area Unit in SS 316 Unit in SS304 cladding for GMP model Jacketed bowl for steam / electrical heating OTHER MIXERS: MASS MIXER DRUM MIXER.

Planetary mixer

Get Price Quote

Planetary Mixer is a vertical batch mixer ideally suitable for mixing of ointments, paste, cream, dry powders or wet mass. Planetary Mixer, as name suggests it has planetary type agitation pattern. The beaters rotate around itself as well as in circular path in the bowl; this enables faster and better mixing of materials at a considerably lesser time. Special Features of Mec-well Planetary Mixer - The bowl fits tightly enough so that mixing can be achieved under Vacuum or pressure for Deaeration. All contact parts are made up of SS-316/SS-304. Electrical Control Panel with PLCs for easy process control. Capacity -25 Ur. to 1500 Ltr. Unit with FLP motors and FLP push button station available. MS parts shall be cladded with SS 304 Q sheet and SS parts will be polished to desired pharmaceutical finish.

Planetary mixer

Get Price Quote

high quality milk/ egg mixer/ blender, perfect supply the material for cake, milk, tea, coffee, etc, 5l and 7l. capacity : 500 to 5000 ltrs..

Cream Mixer Machine

Get Price Quote

The Cream Mixer Machine that we offer delivers efficient and fast cream mixing. It is capable of delivering high outputs. The Cream Mixer Machine has an excellent design and so it is used extensively. The Cream Mixer Machine is easy to use and requires minimal maintenance. These Cream Mixer Machines are efficient and have a long operating life. These machines are available to clients at market leading prices. The Cream Mixer Machine delivers consistent and flawless performance. Specifications Three different speedsMixing bowl has Capacity of: 25 liters per batchStainless steel Mixing bowl blade Three phase motorTotal electric load of 2 H.PSample available