Plastic Injection Molds

32,000 Per piece

1 piece (MOQ)

Plastic Injection Moulds

Get Price Quote

Over the years, we have gradually built up a comprehensive base of product specific know-how in the fields of medical, pharmaceuticals, laboratory equipment, specimen containers, cosmetics, packaging, caps and closures, cutlery, spoon, fork, knife, home appliances, writing instruments, pen, ballpen, sketch pen, electrical, electronics and industrial parts for which we manufacture plastic injection molds, moulds.

Looking for Plastic Injection Molding Services Providers

Chair Mould

100,000 - 500,000 Per Set

We are offering automatic injection moulds.We are also provide injection moulding services and new product development

Precision Plastic Moulding Work

Get Price Quote

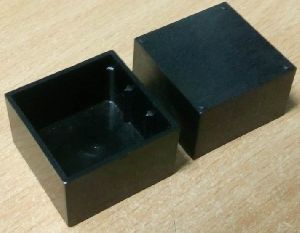

Pioneer in the industry, we are engaged in presenting an impeccable range of Precision Plastic Moulding Work. This plastic work includes manufacturing of various containers used in variety of industry. The container is used for releasing and storing the liquid and powder materials. The offered plastic work materials are manufactured using PBT and other plastic goods. Manufacturing in accordance to set industry standards help in keeping the stored materials safe from moisture and other decaying or reacting solutions. Apart from this, clients can get the such work from us at industry leading rates. Other Details: High tensile strength High durability Prolong self life

Plastic Injection Moulds

Get Price Quote

We manufacture and supply Plastic Injection Moulds of precise make. Materials such as Polystyrene, Nylon, Polypropylene and Polythene can be used in a process called Injection Moulding. These materials have thermoplastic properties, which means when they are heated and pressured in a mould they can be formed into different shapes.

Plastic Injection Moulding Service

Get Price Quote

Injection moulding is a fast procedure used to produce large number of plastic identical items which hold a bracket from technical engineering components to various consumer goods.” If you are seeking professional aid that can handle your plastic injection molding needs, look no further than PP. Operating from Mumbai (Maharashtra, India), we are providing solutions that comply with the codes of quality and clients’ functional needs. We have set up an in-house facility laced with modern tools and techniques thus, top-notch solutions are guaranteed. Clients can reach us anytime for small and big plastic injection molding needs.

Precision Plastic Moulding Work

Get Price Quote

All those who are in search of dependable name providing precision plastic moulding work related solutions, can get in touch with us. MPI is a Mumbai (Maharashtra, India) based organization, specialized in entertaining all sorts of plastic moulding requirements. We have a pool of professionals, who work together and provide solutions as per clients’ requirements. The aforementioned work solutions are rendered in accordance with the elevated trade norms and using premium material 7 new-age moulding techniques. One can get in touch with us anytime for further discussion.

Plastic Injection Mold

29,000 - 30,000 Per Piece

Plastic Injection Moulds

49,000 - 50,000 Per Piece

Plastic Injection Moulds

Get Price Quote

Plastic Injection Molds

Get Price Quote

We bring forth a wide range of Plastic Injection Molds which is designed keeping the requirements of the clients in mind. We offer our Plastic Injection Molds in many dimensions and specifications so that the work needs of the clients are addressed effectively. We even offer the option of custom designing the Plastic Injection Molds as per the specifications provided. We hold expertise in this field which makes us one of the prominent Plastic Injection Moulds Manufacturers. Injection molds are available as Cold Runner & Hot Runner. Types of Cold Runner Molds Two plate moldA Two Plate Cold Runner Mold is the simplest and most common type of mold. It�s called Two Plate because there is one parting plane and the mold splits into two halves. The runner system must be located on this parting plane thus the part can only be gated on its parameters. Three plate moldA Three Plate Mold differs from a two plate in that it has two parting planes and the mold splits into three sections every time the part is ejected. Since the mold has two parting planes the runner system can be located on one and the part on the other. Three Plate Molds are used because of their flexibility in gating location as part can be gated virtually anywhere along its surface Hot runner mold theory With heat manifold and heat drops inserted in injection mold, the resin could keep in the molten state as it flows through the barrel. Then it gate into the cavity just as inject directly from the machine nozzle. No runner and cold sprue will exist during the production. Hot runner benefits Reduce cycle time a lot and then increase the production efficiencyImprove the gating appearanceLittle waste or no waste of the resinThe hot runner could reduce the flow resistance and then the injection pressure and clamp force could reduce a lot. Then it offer opportunity to produce the flow strained partFewer mold-in stress

Plastic Injection Mold

15,000 Per Units

Plastic Injection Moulds

Get Price Quote

We are offering plastic injection moulds and extrusion blow moulds.

Plastic Injection Mold

Get Price Quote

Plastic Injection Moulding Services

5 Per piece

500 Piece (MOQ)

Dear Sir, Greetings of the day! We're thrilled to introduce our business to you! We are AMBE Enterprises, a company dedicated to manufacturing plastic injection molded components. We provide complete job work services for all industries with a commitment to quality, innovation, and customer satisfaction, We strive to offer products at a lower cost without compromising quality, especially in price-sensitive markets. We are capable of executing big or small orders as per customer requirements for this we have types of molding machines under one roof. Our team is passionate about quality, innovation, and sustainability, customer satisfaction, delivering exceptional service, creating sustainable solutions, etc. We look forward to serving you and exceeding your expectations. Feel free to reach out if you have any requirements or if there are any you'd like to know about our services.

Plastic Injection Molding

Get Price Quote

Plastic Injection Molding

Plastic Injection Mold

Get Price Quote

Plastic Injection Mold, Plastic Machining, plastic fabrication

Plastic Injection Molds

Get Price Quote

Plastic Injection Molds, Food Containers, Industrial Products

Plastic Injection Molds

Get Price Quote

Plastic Injection Molds, plastic processing machines, Printing Machines

Plastic Injection Molding

Get Price Quote

Plastic Injection Molding, fishing floats, plastic casting, plastic extruding