Automatic Capsule Filling Machine Spares Parts

Get Price Quote

ACE Most Important Parts of Automatic Capsule Filling Machine You Must Know An automatic capsule filling machine is an assembly of different parts that form a complete system. Broadly, these parts are mechanical, electrical or hydraulic components, which form either stationary or moving sections. In this article, you’ll learn about 13 most important parts of automatic capsule filling machines. These key parts/sections include: Capsule Hopper with Level Sensor Capsule Feeding Unit Powder Hopper with Screw Feeding Powder Dosage Filling Device with Level Sensor Complete Closed Rotary Turret Mechanical Drive System Lubrication System Vacuum System Interlocked Safety Door PLC and Touch Screen Control System Automatic Loading Device for Empty Capsule Automatic Loading Device for Powder Capsule Polishing Machine with Sorter and Metal Detector

Plastic Stool Mould

500,000 - 900,000 Per piece

1 Piece (MOQ)

Best Deals from Plastic Machine

plastic injection molding machines

Get Price Quote

1 piece (MOQ)

Density plastic testing machine

Get Price Quote

Capacity – 200 grams Resolution – 1mg0.01mg Accuracy: +- 0.010.001 No manual calculation requires Direct result on display. Supply: 230 VAC50 Hz Computerised Version available.

Plastic Bag Printing Machine

1,000,000 Per Piece

Plastic Blow Molding Machine

Get Price Quote

We are the leading Manufacturers of Antivibration Machine Mounts & Rubber Molded Products and Parts

Custom Made Plastic Blow Molding Machine

Get Price Quote

We make sure that our inputs are in conformation with the international quality standards and free from all sorts of impurities in order to offer quality-approved products to the buyers. Owing to our state-of-the-art warehouse, we efficiently entertain both automated inbound and outbound consignments with utmost proficiency. The products are sorted and segregated to make sure that the delivery commences systematically.

HPM Thermoforming Machine

Get Price Quote

We make available small-scale version of HPM Thermoforming Machine. These HPM Thermoforming Machines are known for cutting and forming of small-sized jobs. Further, these HPM Thermoforming Machines are available at variable speeds owing to the availability of �cam and follower� assembly. Features : Ideal for installation forming Mechanically driven Helps in integrating moulds with built-in punching dies Assists in cutting containers with flat or semi roller edges Onboard Cam & Follower System

Plastic Recycling Plant

Get Price Quote

Recycling Line with Japanese Technology Developed for Plasticizing & Recycling of LDHDHMHDPP PS FilmBOPPPP Film Machine suitable to process materials in the form of MonoMultilayer Film Waste Highly Printed Film Waste Metalized Non – Metalized BOPP-CPP All the Oriental Product – MonofilamentMulti Filament Non-WovenWoven or Tape or Raffi

plastic molding machine

Get Price Quote

We have a well-developed all the in-house storage facility, laced with all the modern facilities. Also, we have hired a team of professionals who efficiently manage and maintain it. As we are acknowledged for providing high quality products to the clients, we make use of only superior grade raw materials as inputs. The selection of raw material is done by our experts.

DESIGNER CANDLE MAKING COURSES IN MUMBAI

Get Price Quote

Plastic Injection Moulding Machines

1,200,000 - 11,000,000 Per piece

Kindly attn:- Owner / Chairman / Director / Managing Director / Authorised Purchase Head.Dear Sir,We are mfg of new moulds and Are Sole Agents for sales and services provider for Indian market with Dealing of New Injection Moulding Machine Range from 100T to 4000T with having excellent quality and at most competitive reasonable prices & More Beneficiary for the exporters of finished goods.Machinery suitable for Injection Moulded products as for below1.Automobiles2.Battery case3.Furniture and crates4.Caps & Closures5.Computer & Accessories6.Household7.Electrical & Electronics8.Engineering9.Food & Non food containers10.Medical labs11.Paint pails12.Lubricants13.Pet performs14.Pipe fittings15.Textile16.Thin wall containers17.Writing instruments stationery18.Houseware & KitchenwareAnd having all ancillary equipment for support of injection,blow and extrusion plant machinery to run in automation are as1.Hopper & Dryer2.Auto loader3.Mould Temperature Controller (MTC)4.Granulator5.Colour Mixer6.Chiller7.Cooling Tower8.Robot 9.Cleaning Agent for Complete plant water system10.Hotrunner & Controller11.Preventive Maintenance for moulds & machinery12.Annual Maintenance Contract Pls to let us know the exact requirement of machinery1.What kind of product and raw material uses2.What capacity of machinery in Tonnage3.Total Shot weight4.Maximum Mould Size (L x W x Ht)5.Type Toggle or Hydraulic6.Min & Max Cycle time 7.Require Fixed pump or VDP or Servo8.How many quantity of Machinery require in nos. 9.Do you require New Moulds & design ready avail10.How many quanity new moulds require in Nos.11.Robot Require12.Require Ancillary equipment If any requirement pls feel free to provide us your valuable reply with appointment and contact name & numberAnd business visiting card. We provide complete services mfg for plastics industries from Plastics product to moulds to plastics machinery .Most Welcome Proposal for franchises partners & Investors & Buyers at State , district.Awaiting for your valuable feedback for project plan of purchase of capital goodsThanking you

plastic baling press machine

Get Price Quote

1 Piece (MOQ)

Plastic Baling press machine also known as perfect pet bottle baler are standalone vertical machines. The baler is enhanced with pressing force capacity of 88,000lbs. It Produces bales of 80-220 kg. The Techno Hydraulic Works baler is specially designed for areas with space or height limitations. The Baler is specially known for its Dimensional accuracy & Compact Design. They are specially designed to provide effective operation at low cost & pollution free operating. Every Techno Hydraulic Balers are designed for years of reliable, trouble free experience. The size & weight Of the bales can be configured as per the requirement as various merchants has various facilities.

Plastic Tube Sealing Machine

Get Price Quote

water bath machine

20,000 Per Piece

Pvc Injection Moulding Machine

Get Price Quote

MACHINE RANGE – 180 TONS TO 1450 TONSSHOT WEIGHT – 520 GMS TO 11225 GMS Based on the special design screw, upgraded motor torque, and multiple core functions, the PVC-series machines offer a very wide range of application for powder PVC, rigid PVC, and CPVC. The modular base machines ranges from 60 ton to 1450 ton clamp force and machine performance is optimized by offering up to three injection units per clamp size. These series machines are suitable for application in industry, sewer system, horticulture, water supply system, and so on.

50 Litre PVC Blow Moulding Machine

Get Price Quote

Our organization is recognized in the industry for offering optimum quality pvc blow moulding machine. Our offered range has gained appreciation from every nook and corner of the country, owing to its consistent performance, high functionality and low operational cost. Manufactured with utmost care and precision using guaranteed components and leading-edge technology, our offered machine is guaranteed of its functionality. Before the final dispatch from our end, we rigorously test this machine on various parameters of quality. Features : High strength Power efficiency User-friendly interface

Plastic Comb Binding Machine

4,200 Per Piece

1 Piece (MOQ)

Plastic Welding Machine

3,600 Per Piece

Indirect Extrusion Tools

Get Price Quote

Dies and Punches for Aluminium Tube, Can & Containers Sintered Carbide is the ideal material for tooling used to manufacture can, lid & other sheet & metal container. Mikron Engineers implements professional solutions for deep drawing, bending, beading, rolling & punching. Sintered carbide tools make a decisive contribution to optimizing products & ensure uniform product output for a long, long time. “If its carbide tools you need made to stringent quality standards competitively priced and delivered on time we are the right source.” We also manufacture tooling for metal packaging, valve & pump components, precision machine tools

Waste plastic recycling shredder

Get Price Quote

We deal in high quality of the Waste Plastic Recycling Shredders which have been produced using the best technology available around us and they have a very sturdy make. These products are used for recycling plastic so that they can be effectively disposed and they offer an efficient performance to the customers. They have been priced at very reasonable rates in the market.

R-PET SHEET EXTRUSIONS LINE

10,000,000 Per Set

1 Set(s) (MOQ)

R. R. Plast extrusions pvt. Ltd is manufacturers and exporter of plastic extrusion machines. R.r.plast is exporting to more than 40 countries having iso:9001:2008 certification for quality of management system.our machines special feature being r – pet processing without dehumidifier for which rrp has used specially designed triple vented extruder. Also our r- pet sheet line is workable with 100 % bottle flakes and no virgin granules are required.

Ultrasonic Plastic Welding Machine

Get Price Quote

We are the well- known as the foremost Ultrasonic Plastic Welding Machine Manufacturer and Supplier, based in India. The demand for our Ultrasonic Plastic Welding Machine has gradually increased over the time, owing to its efficiency and durability. Our Ultrasonic Plastic Welding Machine is offered at affordable prices. Attributes Extremely low rejection ratesInstance high strengthLow energy consumptionFast processing timesClean weld seams Used For StackingEmbeddingRivetingForming Main Components Transducer /booster/ sonotrodePneumatic Press and Control UnitElectronic ultrasonic Generator Working The Generator supplies the transducer with an alternating current of a given ultrasonic frequency. This is then converted by the transducer into mechanical / ultrasonic vibrations that are finally transmitted via, the booster and sonotrode to the item being welded. Unique Features MicroprocessorUse of printer of welding cycle analysis & parameter settingWelded box structured pneumatic pressOption force triggeringModular designBuilt in electronic amplitude setting: to choose amplitudes between 70% to 100%Energy mode optionAccurate time setting with least count of 0.001 secondShake of pulse-additional ultrasonic vibration at the end of cycleSelf diagnosis-Microprocessor of system Automatic tuning of horn & horn life indication Applications PackagingTelecommunicationsGift and noveltiesTextilesElectronicsAutomativeStationeryWhite goods

Agglomerator Machine

Get Price Quote

Owing to the vast manufacturing unit, we have been able to put forth the clients an excellent assortment of Agglomerator Machine. Fabricated using premium quality raw material, the range is incorporated with a motor and 4 rotary & 4 fixed blades, for the efficient functioning of the machine. Our product is used for feeding of extruder and preheating & mixing of material by converting film scraps of HDPE, LDPE, BOPP, HM, PP and Tapes rafia into dense cubes.

Plastic Injection

Get Price Quote

Plastic injection, Our product array includes Plastic Injection Moulding Machine, Vertical Injection Molding Machine, Injection Moulding Machine With Vertical Clamping and PET Injection Moulding Machine. Specially designed to cater for Plastics components being molded with metal non Metal Inserts as well as can be used for Over Molding. Available from 15 Ton to 200 Tons Locking Sizes with the Option of Single Double station slide for higher productivity. Microprocessor controlled coupled with Hydraulic Locking with strong mechanical structure offers long life with Trouble free operations. Over Molding possibility make machine ideally suitable in Tooth Brush, Table Ware and Automobile products manufacturing.

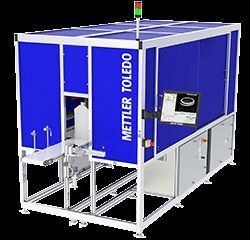

V27 Series for Rigid Plastic Container Inspection

Get Price Quote

Inspection of Rigid Plastic Containers The METTLER TOLEDO V27 series of inspection systems are designed to ensure the proper formation of rigid plastic containers.

Polyester Film Printing Machine

Get Price Quote

WebFlex Machines is popular manufacture and exporter of Polyester Film Printing Machine. The robust construction and smooth execution of jobs are some of the salient features of this machine. UNWIND Unit: Polyester Film Printing Machine unwind unit has specially designed ball bearing assembly to accept standard cores and this is done by incorporating a shaft with tapered reel cones. We have arranged for lateral displacement with mechanical clutch at crucial points for easy operations and also to maintain perfect web tension adequate idle rollers are provided. MOTORISED REGISTER CONTROLS: In order to obtain fine registration of multi-colour prints at operational speeds we have provided Mechanical devices at operating side, which helps during cross as well as lengthwise registration. Similarly compensating roll moving up and down on linear screw system with servo motor is used for longitudinal registration or alternatively for longitudinal registration we also provide SS roll cantilevered by screw and slo syn motor and this is easily operated due to individual panel board which has individual push button controls for smooth and easy operations of the unit. Based on customer’s requirement we provide pneumatic or manual Rubber Roll Impression. Laminated Foil Printing Unit: This laminated foil printing unit is a cylindrical unit and includes removable impression rollers and doctor blade. The roller can be removed for changing, working and making it ready to use. Similarly doctor blade can be removed to sharpen and replace blades. The position and angle can be adjusted of the oscillating doctor’s knife as suitable to the diameter of the printing cylinders. We have fitted laminated foil printing unit on low friction gun metal bushing with mechanical oscillation off the gear box drive. All the units of blades have been made ready with devices for oscillation and change of angles of blade are designed to suit diameter of the cylinders. GEAR BOX: Polyester Film Printing Machine's Gear Box is spiral bevel reduction/oil immersed and fixed at the unit side frame along the machine. It has a mechanical drive for alternate transversal movement of the doctor blade. The adjustable stroke of doctor’s blade is of +/- 9mm. The special feature of Polyester Film Printing Machine’s gear box is the reverse printing facility, we have provided at few stations. REWIND UNIT: In the rewind unit printed web is coiled around the shaft made from steel alloy on a paper core, which is locked by tapered cones provided in the shaft and mounted on ball bearing assembly. Friction clutch mechanical assembly drives rewind shaft and controls the web tension and this enables perfect and tight rewinding without any stretch of the film.

Plastic Grinder Machine

Get Price Quote

Scrap Washing Machine

25,000 Per Piece

Single Screw Extruder

Get Price Quote