Shredders

Feed this SHREDDER by hand or a mechanical feeding device as required for a specific material. The SHREDDER is a heavy duty SHREDDER M/C with sturdy/robust construction for the production of clean granules. The material is processed direct by the specially designed rotor and stator knives and reduced to the desired particle size. The fly wheel effect of the rotar guarantees smooth, shock free running even when there is great stress. The upper part of the machine is easily opened by the swing back system. A switch prevents the motor from starting when the machine is opened. This machine has a Pneumatic Suction Unit which provides additional cooling, ensuring high output. It also enables the shredded material to be discharged wherever required. The size of the particles is decided by the selected mesh size of screen installed in the machine. SHREDDER SR - 5 "Heavy duty SHREDDER with sturdy construction for production of fine particles" It has a Pneumatic Suction Unit which provides additional cooling to the cutting chamber and automatic collection system which increases the blade life and seperates the very fine dust.

...more

pelletiser

PM Strand pelletisers are designed and engineered for high performance. They are the first choice of resin producers throughout the plastic industry. They assure (a) low maintenance, (b) long service and (c) quiet, precise cutting. They come in a versatile range of machines, manufactured to match the requirements of customers for cutting uniform sized pellets out of the strands from plastic extruder machines. PM pelletisers will also cut fibers, thermoplastics as well as rubber. There is also a special model for glass and mineral-filled resins. For Unique Design & Optimal Operation The innovative design of PM pelletisers has many unique and useful features. The larger diameter of the upper feed roll and its close proximity to the rotor eliminates the need of the stripper bar used in conventional machines. The alignment of the feed plane and the twin rollers prevents bunching up of plastic strands and deformation of the upper feed roll. By the positioning of the feed table and the bed knife lower than the centre line of the rotor, the strands remain flat while being drawn to the rotor's cutting edges, ensuring a clean cut. Our helix-angled rotor is a specially designed component which contributes most to the cutting edge comes down, it progressively shears a single row of pellets from the incoming strands. Just as it finishes its cut, the next cutting edge starts shearing the next strand. This ensures that each strand produces a pellet exactly the same size as previous ones. The cleaner cut made by these helix-angled edges produces minimal percentages of "overs" and fines, also with less torque and much less noise. For Quality & Safety The cutting chamber design is uncluttered and affords easy access. A safety interlock is provided so that the pelletiser cannot run when the cover to the cutting chamber is raised. In short, PM palletisers ensure safety, high production capacity at lower RPM, low noise levels and above all, quality output. All these features are crucial for success in the highly competitive and increasingly quality-oriented environment of our plastics conversion industry.

...more

granulators

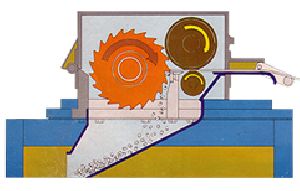

In the production and preparation of plastics, rubber and chemicals, size reduction machines play a major role. In plastic processing plants, in particular, moulding excesses, scraps, damaged articles etc. accumulate. These are reduced to granules of required size by our grinders. The granules can be recycled, simplifying production and increasing profits. PM - G - 1 Special features › Heavy and sturdy construction makes the machine versatile and able to work under difficult conditions. › Quick exchange of sieves enables machine to produce coarser and finer granules according to ones requirement. › Easy accessibility of the grinding chamber, easy cleaning by opening the front lid. › Special toggle type limit switch is connected to prevent any unintentional turning of rotor when cleaning or changing knives or sieves. PM - Grinders Special features Feed this grinder by hand or a mechanical feeding devices as required for a specific material. The grinder is a heavy duty granulator with sturdy/robust construction for the production of clean granules. The material is processed directly by the specially designed rotor and stator knives and reduces to the desired particle size. The fly wheel effect of the rotor guarantees smooth, shock free running even when there is great stress. Also the upper part of the machine is easily opened by the swing back quick lock system. A switch prevents the motor from starting when the machine is open. This machine can also have a Pneumatic Suction Unit which provides additional cooling, ensuring high output. It also enables the ground material to be discharged whenever required. The size of the particles is determined by the selected mesh size of the screen installed in the machine. Note : Pneumatic collection system can be provided to any model manufactured by Plastic Machineries.

...more

Automatic Bag Opening DEVICE

In Fiber Handling Section of Fiber Cement Sheet and Pressure Pipe Plants Operating of automatic bag opening device: The function of the equipment is to open the raw fiber bags automatically in a totally enclosed container without leaving any dust outside. Removal of the empty bags, discharge of the press packed fibers in to the lump breaker and breaking the lumps in to fibers. It also shreds the empty fiber bags into fine particles which are ultimately conveyed along with the fiber. When equipment is used properly, with all automatic functions, the chances of emission of dust to open atmosphere are practically nil.

...more

asbestos bags

The function of the equipment is to open the raw fiber bags automatically in a totally enclosed container without leaving any dust outside. Removal of the empty bags, discharge of the press packed fibers in to the lump breaker and breaking the lumps in to fibers. It also shreds the empty fiber bags into fine particles which are ultimately conveyed along with the fiber. When equipment is used properly, with all automatic functions, the chances of emission of dust to open atmosphere are practically nil.

...more

CoolStar Dicers

Dicers are designed for the manufacture of square granules of uniform thickness from different plastic materials. The machine uses thick plastic sheets received from the roll mills or from extruder can take sheets of width up to 600 mm and thickness up to 4 mm. Each such sheet is first slit into strands; these strands are then cut into up to 4 mm length granules. Thus, quality granules of uniform size and shape are produced with less wastage and high throughput. The machine is sturdily built to give continuous and trouble free service. These machine can also be supplied to suit different specifications for other granule sizes. They can be specially fabricated to meet the special requirements of plastic processing units. These machines have got options for a drive of A.C. variable speed drive. A safety interlock is provided so that the dicer can not run when the cover of the cutting chamber is open. Corrosion protection is ensured by the use of stainless steel in all contact parts.

...moreBe first to Rate

Rate ThisOpening Hours