Pneumatic Loading System

Get Price Quote

Pneumatic Conveying Systems

Get Price Quote

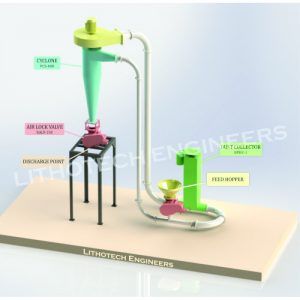

The Pneumatic Conveying system will convey the powder from the Pulveriser into the collection bin. It will separate the air from the material thereby preventing dusting. The air will exit through the Dust Collector. The constant circulation of fresh Air into the system ensures powder to remain cool.

Best Deals from Pneumatic Conveying System

hydro pneumatic systems

Get Price Quote

he series Z Hydro-Pneumatic Systems have been developed for applications where two or more Cylinders have to be operated from a single Reservoir-Intensifier Power unit. They are also useful for applications requiring a large travel under load (large Power Stroke) and for applications where the length of our standard ‘N’ series Hydro-Pneumatic Press systems cannot be accommodated.

Hydro Pneumatic System

Get Price Quote

Aguapuro offers Hydro-pneumatic Booster System for consistent flow and pressure for various Applications. Hydro pneumatic booster system is designed either with single or with multiple pumps to have continuous water pressure. Systems are also designed with Variable Frequency Drive Unit. Various types of Pumps are used for pneumatic booster system depending upon Application and use. Booster Tank is used to get smooth operation of the Pump allowing pump to work for minimum 1/2 to 1 min. Piping and Valves are used for making system easy. Applications Commercial Offices and Industries Clubs & Sports Complex Residential requirement Restaurants & Hotels Food Joints & Resorts Water Treatment Plants

Hydro-Pneumatic System

Get Price Quote

Advanced Features• Auto ON/OFF as per water requirements• Optimum utilization of all pumps by cascading effect• Cascading of pumps after each high-pressure CUTOFF• Dry run protection using pressure sensing• START/STOP Delay times to prevent pumps from frequent ON/OFF• Thermal protection by using thermostat inside motor• Protection against phase reversal & Single phasing• Motor burning protection by using current based cut off• Automatic changeover of pumps during operation• Monitoring pump running time in PLC• Indication of error signal in BMS screen(Parameter monitoring BMS compatibility available on request)• Use of standby pump as a duty assist at increased demandsOperating Conditions• Liquid: Clear water without any contamination• Temperature: 0 to 900 C• Site conditions: Maximum ambient temperature 550 C• Min Suction Pressure: NPSH of the Pump + 1.5m• Voltage: 1PH - 180 to 240 V, 3PH- 380V to 440VControllers• CT(Fixed Speed) Controller: Fixed speed controller with PLC to START & STOP system as per water requirement. Device used for pressure sensing is Pressure Transmitter• CV(Variable Speed) Controller: Variable speed Controller with PLC to Smooth START & STOP the system as per requirement. Device used to sense pressure is Pressure Transmitter. This contains single external VFD to start pump smoothly & cater small water requirements efficiently• CM(Multi VFD) Controller: Variable speed controller with PLC and individual VFD, START and STOP all pumps smoothly as per requirement. This controller increases the pump and system life, reduces pump maintenance, operates all pumps at there maximum efficiency Applications • Domestic water supply• Residential & commercial buildings• Irrigation of small farms• Hotels, Resorts, bungalows, Villas, apartments etc.• Horticulture irrigation

Pneumatic Conveyor System

Get Price Quote

Pneumatic Conveyor System, Pneumetic Conveyor System, Air Handling Blower

Hydro Pneumatic System

Get Price Quote

Hydro Pneumatic System, drinking water filters, Membrane Bio Reactor

Hydro Pneumatic System

Get Price Quote

Hydro Pneumatic System, Beverage Processing Equipment