AIR CONVEYOR

Get Price Quote

To ensure maximum quality retention, we package our products in industrial-grade packaging materials that can brave mechanical damages and logistical jostling. Additionally, they are labeled to impart product information. Due to our exceptional and completely secured payment procedures, we have successfully gained full customer satisfaction. We make available varied payment procedures to ensure smooth transactions. Features : Sturdy design Safe use Easy installation.

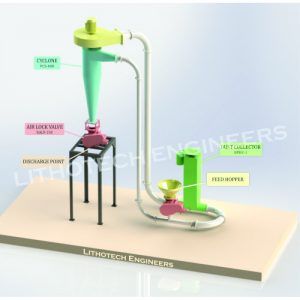

Vacuum Powder Transfer System

Get Price Quote

3 Piece (MOQ)

VACUUM POWDER TRANSFER SYSTEM (VTS) - (Capacity: Up to 3000 Kgs/hr) GMP Model VACUUM TRANSFER SYSTEM is unique equipment used for Transferring the powder/product into process equipment. By using this equipment, a dust free charging can be done as compared to conventional type or manually charging. This equipment comprises of two units. One is the Vacuum Blower and Other one is a powder receiver bin with filtration unit. Powder receiver Bin located above the equipment which you intend to transfer powder/ product. These units will be connected through a food grade flexible thunder hose. SALIENT FEATURES Manufactured as cGMP Norms. Vacuum Blower is used. Which eliminates lubrication system and Motor, Pulley V Belt Etc. . Consumes 40% power compared to the other conventional Equipment. All sides on the shell are curved construction. Totally eliminates sharp corners and cleaning difficulty. Finish: Inside : Mirror Polish Out Side Matt polish Capacity : UP to 3000 Kg/Hr.

Best Deals from Pneumatic Conveyors

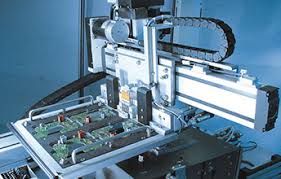

electro pneumatic system

Get Price Quote

1 Piece (MOQ)

Stainless Steel Powder Vacuum Transfer System

Get Price Quote

1 Unit (MOQ)

Vacuum Powder Transfer System

Get Price Quote

EMCO VTS technology provides innovative solutions for automated transfer, dosing and packaging of powders by means of vacuum and pressure. VTS with its unique filtration concept makes the only vacuum dense-phase system that functions at optimum levels when handing ultra-fine, sticky and adhesive powders. VTS* (Vacuum Transfer System) Dust Free Filling and discharging Packaging Dosing No product retention No particle damage Easy to clean

hydro pneumatic systems

Get Price Quote

he series Z Hydro-Pneumatic Systems have been developed for applications where two or more Cylinders have to be operated from a single Reservoir-Intensifier Power unit. They are also useful for applications requiring a large travel under load (large Power Stroke) and for applications where the length of our standard ‘N’ series Hydro-Pneumatic Press systems cannot be accommodated.

Pneumatic System

Get Price Quote

Auto operation based on Level & Differential Pressure by PLC-VFD, PID & Differential Pressure Transmitter or Pressure Switch.

Pneumatic Conveying System

Get Price Quote

From pebble lime to peanuts, from coal to baby powder - and everything in between – pneumatic conveying has long been a popular choice for moving bulk materials, either from storage facilities to a process unit, or between process units. Two most distinct categories of pneumatic conveying can be described as either dilute-phase or dense-phase systems. These have been developed over the past few decades to take advantage of the different behavioural properties of bulk materials and also to meet the increasingly demanding requirements of industry in the areas of system reliability, product quality control and energy efficiency. Pneumatic conveying systems are basically quite simple and are eminently suitable for the transport of powder and granular materials in factory, site and plant situations. The system requirements are a source of compressed gas, usually air, a feed device, a conveying pipeline and a receiver to disengage the conveyed product and carrier gas. With suitable choice and arrangement of equipment, materials can be conveyed from hopper or silo in one location to another location some distance away. Considerable flexibility in both plant layout and operation are possible, such that multi-point feeding can be made into a common line, and a single line can be discharged into a number of receiving hoppers. Flow rates can be controlled easily and monitored to continuously check input and output, and most system can be arranged for completely automatic operation.

Pneumatic Conveyors

Get Price Quote

A vast team of employees ranging from designers, project engineers, proposal engineers, sales & marketing engineers, engineering draughtsman, purchase, accounts & other crucial departments that streamline the functioning of Macawber.

Pneumatic Conveying System

Get Price Quote

Shree Udyog specialises in manufacturing different types of pneumatic conveying systems. Years of experience have helped us pioneer the design for various material conveying systems. Our Pneumatic conveying systems provide high efficiency and have been tried and tested in various industries for their better performance. We only make use of high-grade raw material to manufacture our products. We make use of different materials depending upon the requirement of material to be conveyed. Material Conveyed: Food Grains Pulverized material Plastic granules Polymer chips Plastic grinding Material Conveying Plastic Chippings Paint Powder Industries Catered: Plastic / Polymer Industries Agro Industries Paper Mills Paint processing Textile Industries Wood working industries Pharmaceutical Industries Powder processing Industries Tobacco Processing Industries Food Processing Industries (Grain Handling) Plastic / Polymer Printing and Processing Industries Machines Compatible: Some of the machines that our dust collection systems are used with are listed herewith: Polishing / Surfacing Machines Rubber Grinding Machines Surface Grinding Machines Wood Cutting Machinery Sand Blasting Machines Sand Blasting Machines Small Machine Tools Cutting Machines Honing Machines Drilling Machines Milling Machines How to order: When sending an enquiry kindly specify the following: Volume of air to be displaced (units: m3/hr. | c.f.m.) Total static pressure. Please specify pressure to be considered at working conditions or NTP. (units: mm of wgp | inches of wgp | mm of Hg | inches of Hg) Temperature or humidity conditions. Direction of rotation from while viewing from suction end. Direction / Position of discharge. (refer direction image, Incase the direction/position is not specified we will supply the fan with clockwise direction of rotation and C1 discharge position.) Cross section of discharge (round | Square | rectangular)

Pneumatic Conveying System

Get Price Quote

We are offering pneumatic conveying system. our company is instrumental in offering a broad range of pneumatic conveying system, as per the requirement of the client. Our pneumatic conveying system finds great applications in mixers, mills, tablet press, sifter and many more. Pneumatic conveying system offered by us is durable, easy to operate and available with mobile trolley mounted version. This pneumatic conveying system is available at most competitive prices. features can be used for transfer of products having bulk densities up to 1.0gm/cc total discharge no retentionno segregation or degradation of productcompact design, complying with current international gmp norms universal adaptability can be easily installed on any receiving equipment like process tank, ibc, conical mill, pin mill, blender, tablet press etcadaptors provided to suit existing inter opening on user's equipmenteconomical and easy to install and operateall contact parts made of ss304 / ss316 / ss316l and pharma grade gaskets / seals no use of oil or grease in any of the contact partsmobile trolley mounted version also available applications for charging of rmgsiftermillmixerblenderbintablet press

Pneumatic Automation System

Get Price Quote

Pneumatic Conveying System

Get Price Quote

Pneumatic conveying is a core technology in the development of bulk material handling systems for the process industries. Pneumatic conveying technologies are divided in vacuum conveying and pressure conveying.

Hydro Pneumatic Booster System

Get Price Quote

We are a trusted Manufacturer and Exporter of Hydro Pneumatic Booster System that is designed keeping the requirement of various industries in mind. Our range of Hydro Pneumatic Booster Systems is equipped with single or with multiple pumps to have continuous water pressure. We offer Hydro Pneumatic Booster System at market leading prices. Known ForSmooth operationEasy installationLow maintenance costHigh efficiency ApplicationsCommercial OfficesIndustriesClubs & Sports ComplexResidential spacesRestaurants & HotelsFood Joints & ResortsWater Treatment Plants

Pneumatic Conveying System

Get Price Quote

Pneumatic Conveying System (Dilute Phase Conveying) Pneumatic Conveying has decisive advantages in conveying dusty products over mechanical conveying, low space requirements and low maintenance. Also it is flexible in construction, can be easily automated, provides dustless conveying without loss of material and is thus also safe for products hazardous to health. A conveyable product is transported through a pipe by using a certain quality of gas [air or nitrogen]. The product particles are freely moving with the high gas velocity and a low product to air ratio. The different types of Pneumatic Conveyors are A) Vacuum Conveying System : D. P. Vacuum Conveying System works on negative pressure for conveying the material from one or number of pickup points to one discharge point. This system is best suitable for providing dust free conditions around inlet. B) Pressure Conveying System : D. P. Pressure Conveying System conveys bulk material by air under pressure. This system offers advantages of conveying material from one place to one or number discharge points. C) Combined Vacuum-Pressure Conveying Systems : D. P. Combined Vacuum- Pressure Conveying System conveys the material from various pick-up points to various discharge points, it is also used where vacuum pick-up and pressure delivery is required. D) Closed Loop Conveying System : D. P. Closed Loop Conveying Systems are designed for handling, explosives and hazardous materials. The conveying gas is usually nitrogen for explosive materials, and dry air is used for handling hygroscopic materials.

electro pneumatic brake system

Get Price Quote

The electro pneumatic brake system consists of an electrically controlled air brake for normal service use giving extremely sensitive and rapid application of the brakes, together with well known automatic air brake providing a “ stand by” brake to be used for normal service stops, if required. The Automatic brake also provides for emergency application of the brake initiated by the driver, the guard, or by a breakaway. Self lapping E.P. brake can be graduated in application and release. Standby self lapping automatic air brake has graduated application and direct release feature. The brake system is suitable for EMU cars operating in multiple. Modular Panel design eliminates piping & complicated casting, easily retrofitted in existing EMU coaches.

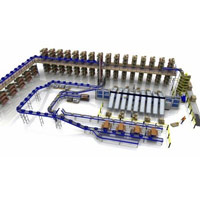

AIR CONVEYOR

Get Price Quote

1. USED FOR CONVEYING BOTTLES FOR FILLING LIQUIDS IN IT.

Pneumatic Conveying Systems

Get Price Quote

The Pneumatic Conveying system will convey the powder from the Pulveriser into the collection bin. It will separate the air from the material thereby preventing dusting. The air will exit through the Dust Collector. The constant circulation of fresh Air into the system ensures powder to remain cool.

Hydraulic Pneumatic Expander System

Get Price Quote

We are offering hydraulic pneumatic expander system. This devise extends the limits of the operation above those of the air-operated models. It will expand heavy wall tubes of copper, brass, cupro-nickel or even low carbon steel. It is not designed for stainless steel or aluminium tube however. This model operates satisfactorily on heavy wall tubes between 38" (9.5 mm) and 34" (19 mm) o.d. the sizing tool may be simply changed for different tube diameters. The basic model is furnished with 1 h.p hydraulic system, connecting hoses of adequate length and complete operating controls. Sizing tools for standard i.d's and sized depths are available. pressure - 0 to 5000 psi & customer requirement upto 100000 psi.

Ring Vac Air Operated Conveyors

Get Price Quote

The Nex Flow Ring Vac Air Conveyor is available in both ANODIZED Aluminum, Heavy Duty HARD Anodized or ALL STAINLESS STEEL. Simply clamp a standard hose size to each end of the Ring-Vac™ to create this high energy conveying system. No moving parts for maintenance free operation with capacity and flow controlled with a pressure regulator. Known as Hopper Loaders or Venturi Loaders, originally designed to eliminate manual bending and lifting. Conveying rate depends on density of material ( Lbs / cubic foot ), horizontal run, vertical lift. These vacuum conveyors provide a simple, low cost solution compared to other pneumatic conveying systems APPLICATIONS Hopper loading Fiber tensioning Material conveying Waste/trim removal Chip removal Part transfer Filling operations ADVANTAGES Compact Quiet No moving parts Fits standard hose or tube Aluminum or stainless steel High throughput capabality