Polishing Pan

Get Price Quote

Polishing Pan

Get Price Quote

Coating Pans are used for coating of tablets and drying them simultaneously by hot air. Thermostat provided for easy selection of required temperature. Damper provided for inlet air control.

Best Deals from Polishing PAN

Polishing Pan

Get Price Quote

Coating/Polishing Pans

Get Price Quote

COATING / POLISHING PAN

Get Price Quote

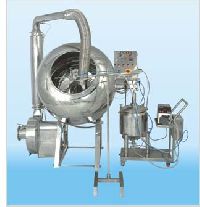

Coating Pan designed by keeping in mind needs of universal conventional coating requirements such as rotational speed, angle of inclination of pan, inside finish of pan, total volume, temperature of air and exhaust arrangement. Special Features : Coating Pan drive can be availabe with VFD for pan speed variation which required in both film as well as sugar coating. Spraying systems is also available with the unit. Polishing pan is made suitable on the same drive of coating pan drive. Hot air / Cold air blowing system is used for tablets. Model available in sizes 12", 24", 30", 42", 48", 60" and 72". Hot air blower system with mobile trolley and filter housing will be provided with TIC or PID type temperature controller for control of air temperature within the range of 50 degree C to 80 degree C. Hapa filter unit (optional ) can be provided along with inlet ducting lines. Other options such as FLP motor and panel, steam heating unit can be provided.

Polishing Pan

Get Price Quote

Pharma machine are renowned for the supplier of sturdy, easy to uphold, robust and long lasting traditional revolving Coating Pans in national and international market. Coating pans are made from high tensile stainless steel hence it is accessible by separate hot air blower system for film coating of tablet.

Polishing Pan

Get Price Quote

Coating Pan are made of stainless steel all contact parts of S.S 304, S.S 316, S.S 316L The unit is Equipped With suitable hot air Blower with thermostatic Control. No foundation requirement. Models available from 12” –24”-36”-48” - 60” Adaptability for lower size of coating pan & polishing pan. Validation documentation can be provided on request. Matching exhaust blower available. Heaters & blowers are electrically interlocked. Perforated bowls with suction device for increased productivity, energy conservation and dust control. Standard & GMP models are available.

Polishing Pan

Get Price Quote

COATING PAN is widely used for Sugar coating & Film Coating of tablets, granules, food products, confectionaries etc., by offering a variety of production options particularly for food and pharmaceutical products. Made In SS-304 316, In Gmp Non-Gmp Models.Baffles Provided In Pan To Reduce Coating Time � Optional, Blower Also Provided In SS �304 For Gmp ModelsElectric Heaters Or Radiators For Hot Water Steam For Hot Air Blower Optional, Spraying Unit For Film Coating Or Sugar Coating, Homogenizer For Online Mixing Of Spraying Liquid Optional, Pan to Polishing Pan.

Polishing Pan

Get Price Quote

The Conventional Coating Pan is simple unit, which employs the principle of rolling a batch of tablets in an elliptical pan, spraying the coating solution on it and passing hot air across the tablet bed. An exhaust blower may be used to carry away the excess fumes generated during the coating and drying process. Gem manufacturer Conventional Coating Pan of various capacities ranging from 12” lab model to 72” conventional types.

Polishing Pan

Get Price Quote

SALIENT FEATURES: Model - 12, 24, 36, 42, 48, 60, 72 inch Dia. The gear box, motor & hot air blower are enclosed in a SS, in case of GMP models. Mounted on dynamounts to avoid foundations. Heaters interlocked with the blower fan. Spray system with pressure tank and spray gun. (Mini Cota) Peristaltic pump for metered dozing. Exhaust blower as optional.

Polishing Pan

Get Price Quote

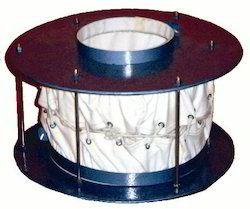

The process of coating tablets and confectioneries depends to a large extent on the personal skill of the coater. Some of the important factors which affect the process of coating are: Rotational speed, Angle of inclination of Pan, Volume and Temperature of hot air, and shape of pan. Coating Pans are incorporated with the above design features and are available in various sizes. Other geometrical shapes and angles can also be provided as per requirement. RPM of Pan can be kept fixed or adjusted by a vary pitch pulley or ac frequency unit. Hot air blower is provided to feed hot air at 40� to 80�C temp, controlled by a thermostat. Quantity of hot air can also be controlled by a damper. Polishing Pan with canvas lining available as optional with quick and easy mounting arrangement for mounting on to drive hub. Coating Pan have very heavy & sturdy structure , made from M.S. Structural material and covered from all sides. SPECIAL FEATURES Temperature controller provided for temp. controlling. Compact hot air blower with inlet air damping arrangement. Easy mounting arrangement for change over from Coating Pan to Polishing Pan.

Stainless Steel Mirror Polished Frying Pans

Get Price Quote

100 Piece (MOQ)

Polishing Pan

Get Price Quote

Polishing Pan, Processing Machinery, Packaging Machinery

Polishing Pan

Get Price Quote

Polishing Pan

Polishing Pan

Get Price Quote

Polishing Pan, tanks vessels