Rusk Packing Machine

Get Price Quote

We are offering rusk packing machine, rusk packing machine belongs to the family of the finest quality rusk pack machines that are manufactured with a minimum speed of 45 – 80 pouches per minute with pouches weighing between 100 gm and 400 gm. The cross seals are of high quality and obstruct the movement of rusk during transportation and storage processes.

Vacuum Packaging Machines Mini

Get Price Quote

We are offering Vacuum Packagin Machines. Technical Specification : » Seal Length : 500mm » Chamber Size : 575 x 575 x 60Dmm » Seal Width : 8 » No. Of seal bar : 2 » Approx Packing Qty. One Shoat : 4 No. » Approx Packing Time Of One Shoat : 45-60*sec. » VACUUM PUMP 280Lt. (Toshniwal Make) : 1 H.P. » Overall Dimensions Approx : H800 x W680 x D750mm » Power Supply 3phase 415vac 50Hz. : 1 HP » Weight approx : 250Kg. Standard Features : » Programmable Digital Control Panel. » Flat working surface for easy operation. » Stainless Steel Housing. No Sharp Edges. Easy To Wipe. » Cutout of Toughened Glass to View the Packaging Process from the Top. » Entirely Made from Stainless Steel, Cast Aluminium & other non ferrous materials. » Oil Mist Separator to remove the Oil mist from Vacuum Pump exhaust. » Soft ventilation – A gradual air influx for ventilation process to compensate Pressure to save the product appearance and material.

Best Deals from Pouch Packaging Machines

chamber machine

Get Price Quote

We have four models of chamber machines designed for customers with different production needs to reach an optimum ratio price/performances and reliability in time. Different production requirements are satisfied by the four distinct chamber machines models. Standard shrinking magnet assembled on machine, washable stainless steel lower chamber to grant better hygiene in foodstuff packing, six working programs available directly by the electronic control panel that drive all machine functions (and automatically adjust sealing time, avoiding fumes caused by sealing blade overheating), sealing by adjustable impulse blade, security thermostat with warning signal to find out troubleshooting, sliding trolley and adjustable working surface, film micro puncher, motorized winder, are the features of FM range. Two working possibilities (sealing only or sealing + shrinking).

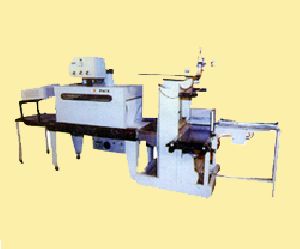

Automatic Sleeve Wrapping Machine

Get Price Quote

ADVANTAGES : * No use of bottom tray * No manual Interaction

Shrink Packaging Machines

Get Price Quote

We are offering shrink packaging machines. we are offering this shrink packaging machines - st-basic/st-12 that caters to various applications and requirements of various industries. This shrink packaging machines is capable of running on three phases that too without any change. Moreover, our shrink packaging machines just requires 200volt/single face 4.5 kw/hr. This shrink packaging machines is widely appreciated for its thermostatically controlled shrinking temperature. The power consumption in this shrink packaging machines is minimized by the usage of uniform shrinkage to sleeve on the product so that air can circulate in proper manner. We are offering this shrink packaging machines at market leading prices. features of shrink packaging machines product speed 600-720 pack per hour depending on the size of the itempower require-200 volt / single face 4.5 kw/hr (can run on three phase also without any change)half of the installed power is used in continuous operation resulting very low of energy consumption (2.5 kw/hr)thermostatically controlled shrinking temperaturepre adjusted speed of the conveyor as per the product to get good finishto minimize the power consumption and to give uniform shrinkage to sleeve on the product the chamber is designed in such a way so that the air can circulate in a proper mannercan handle variety of sizes / shapes, without any change of partsonly 10 minutes start up timecan shrink the films without sealing from all the sidesmachine can use for shrinkable film such as pvc and imported polyolifin applications packing of empty mono cartons, cartons, crates, box at the end of packing line

Protective Packaging Machine

Get Price Quote

Peanut Kernels

Get Price Quote

Catering to the customers needs with excellence, we, as a Supplier engaged in offering a qualitative array of Peanut Seeds. We make sure that all our products are in compliance with the industry standards and thus cross checked at all stages including manufacturing, warehousing, packaging and final dispatch.

horizontal flow wrap machines

Get Price Quote

This Model is suitable to pack products in 1/2/3/4/5 piles of biscuits. The same Model can also be used for paking tray type or for Pre-wrapped Products. Lug carries required number of products from the magazine and arrives to the forming box. The wrapper is wrapped around the forming box. Fin seal at bottem is completed by three pair of rollers out of which one pair is for pre heating, second for heating and third for propelling purpose, which controls the wrapper around the periphery of the product. The crimping jaws makes cross sealing at two ends and seperation as required, such packets are delivered to the out feed conveyor. Automatic self contained unit. All components coming in contact with product are of stainless steel or Food Grade plastic. Ease of change over to differnt varieties of product in minimum time. A.C. motor with variable frequency Inverter Drive. Separate Temperature Controllers are provided for each pair of Heating rollers and jaws. Cut off Length adjustment by just rotating wheel with Display. Simple to operate and easy to maintain.

Groundnut Kernels

Get Price Quote

Groundnut is the major oilseed of India. It accounts for around 25% of the total oilseed production of the country. Annual production of Indian Peanuts and Indian Peanuts oil are around 5-8mln and 1.5 mln tons respectively. Peanuts Production is highly vulnerable to rainfall deviations and display huge fluctuation between years. Regional estimates are Gujarat (1-3.5 million tons), Tamil Nadu (1million tons), Andhra Pradesh (1-2 million tons), Karnataka (0.5 million tons), Maharashtra (0.5 million tons) are the major producers of Peanuts. Around 75% of the crop is produced in khariff (June - September) and remaining 25% in rabi (November - March). India exported around 100000 tons of groundnut oil in 2003-04 after 4 decades, as crop failed in Senegal and Argentina. Peanuts or Groundnut kernels are approx. 70% of weight in shells and kernels have an oil recovery of 40-42%. China (2-2.5 million tons), India (1.5-2 million tons) is the major producers of groundnut oil, followed by Sub-Saharan African countries and Central and South America. Global trade of Peanuts or Groundnut oil is to the maximum of 100000 tons a year. EU and US are major importers. Senegal and Argentina are the major Peanuts exporters. Factors Influencing Peanuts or Groundnut Markets Weather at the major domestic producing centre. The southwest monsoon is the most important factor that determines the area sown, production and prices. Price of other competitive oils in India, viz., soy oil, palm oil, cottonseed oil, sunflower oil and mustard oil. International price movement of soy oil at CBOT and palm oil at BMD, Malaysia also influence the groundnut oil prices. Festivals and celebrations also increase consumption and the prices.

Automatic Milk Bag Packaging Machine

350,000 Per Piece

blister packaging machine

Get Price Quote

Blister Packaging Machine Model BPM-500 has been widely used for the package of hardwares, toys, daily used articles and electrical elements. The commodity packed is featured as transparent, damp proof, dustproof, secure and pleasing to eye.

Shrink Packaging Machine

45,000 Per Piece

1 Piece (MOQ)

Semi Automatic Bottle Packaging Machine

Get Price Quote

Automatic Blister Packing Machine

Get Price Quote

Catering to the specifications and exact drawings of the clients, the Automatic Blister Packing Machine, which we offer, is used in Pharmaceutical industry. This Automatic Blister Packing Machine is used for powder coating or painting the product. These Automatic Blister Packing Machines are easy to maintain and power-efficient. Highlight Back up with laser cutting and CNC endingCustomized solutionsEasy to maintainHassle-free performance

Flow Wrap Machine

Get Price Quote

For-Bro offers state of the art horizontal flow wrap machine for Static solid products in a unit pouches. The machine is able to provide center seal pouches made of heat sealable laminated or virgin film. Machine is available in standard and GMP models suitable for food and pharmaceutical and Chemical industries. Microprocessor or PLC based controls offers easy communication with the machine without need of skilled resources. Automatic staking and placing mechanism is provided for quicker operations.

Secondary Packaging Machines

Get Price Quote

Peak Production Speed Up to 30 loadshr, Peak Production Speed 48″L x 44″W, Maximum Load Wrap Height 75″, Maximum Load Weight 4000 lbs, Turntable Speed (Variable) 12 RPM, Turntable Size 65″ diameter, Turntable Drive 1 HP TEFC.

Semi Automatic Pneumatically Operated Vacuum Pack

Get Price Quote

Semi-Automatic Pneumatically Operated vacuum pack & sealing machine :-MODEL PVPN 600 H Is use to pack and seal product in pre-formed pouches .Aluminum bags made out of heat seal able laminated film to enhance the self life of product. Material: - nylon bags bags of 25 ltrs etc. Features: 1 bag /min Pouch Dimension: 1000 MM X 800 MM Compressor Air Required 30 cfm@ 6 Bar. (Exartnal ) Power Supply: 220 V AC, Single Phase, 50 Hz, 4 KW. GMP and Fully Flamfroop Model. Dimension: L: 1000 Mm, W 800 Mm. H: 1200 mm. Machine Net Weight: 150-200 Kg. (approx. You’re following details on PP bag size and bag weight at 25 kg. Aluminum bag size – Length – 15 INCH Aluminum bag size – Width–25 INCH Speed of Bagging per minute – 1 Bag (Existing system – picture attached) Inner bag (inside Aluminum bag)- Aluminum thin bag Speed Of The Machine Depends On: Size of the pouch Degree of vacuum required Packing material Type of product Operators efficiency External Vacuum Packaging Machine With complete functions! It has 2 functioning pattern can be choosing: 1. only do process of sealing. 2. Vacuum-pumping and sealing. Without limitation caused by the size of vacuum chamber, the air extractor packaging machine has very wide application range. Application (External Vacuum Packaging Machine): The External Vacuum Packaging Machine has very wide application range. Technical Characters(External Vacuum Gas filling Packaging Machine): 1. Control System: Analog and Digital controller. 2. Main housing: high strength armor plate with beautiful spray painting, Stainless steel 304 can be customized! 3. Machine owns double nozzles in chamber less design. 4. The Special sizes of sealing bar can be customized! 5. Double Sealing Bar can be customized!

Form Fill & Seal Machine For Granules

Get Price Quote

Features:Vertical Form Fill & Seal machine for Producing the centre sealed sachet handling all type of free flowing & non - free flowing product. A robust machine with Particular construction for Minimum maintenance and easy adjustment which gives high reliable output. All Parts in contact with products are manufactured in stainless steel. Accurate Sealing die temperature control and Fully controllable die pressure. Cut off blade for separating Sachet from film web housed in horizontal die for maximum efficiency. Photocell Print registration, Comprehensive Push Button control panel with cycle counter, front safety guard and access doors are electrically interlocked.

Automatic Blister Packing Machine

Get Price Quote

We are leading Manufacturer and exporter of Blister Packaging Machine in India. We now have exported our machines to countries that are various Egypt, Ghana, Iran, Kenya, Nigeria and so many more. Blister Packing Machine, blister packing, Versatility for this equipment suits your total packaging needs. Alu blister machine, automatic blister packing machine, blister packaging machines, blister machine and Blister packaging machine from Mumbai, IndiaImpact Labs offered manufacturer of Blister Packaging Machine to develop to flawlessly handle automatic loading, filling operations in addition to meets the demands of non-stop feeding. You can expect these machines in various specifications and will be customized depending on the guidance of this client to meet the varied needs’ at leading market rates. Providing for continuous motion sealing that is rotary, they are ideally fitted to high blister output. Further, these also come with rapid tool-free changeover, thus ensuring more output capacity and intermittent motion platen sealing support providing you with complete process reliability even at medium output speeds.

Vertical Form Fill Seal Machine

510,000 Per