V Blender

Get Price Quote

CYCLONE rotating shell V-Type blenders are used only for dry mixing. They are totally enclosed to prevent any foreign particles to enter into the chamber. Modifications such as the addition of baffles to increase mixing shear can be made to these type of blenders.Features : Minimal Attrition when blending fragile granules. Large-Capacity equipment available Easy to load and unload Easy to clean Minimal maintenance Available in various capacities from 25 liters to 1000 liters.

Mass Mixer

Get Price Quote

General Specification: Shell : Consisting of ‘U’ trough of suitable dimensions. Construction of S.S and side plates duly M.S stiffened from outside and from inside with S.S. Mixing Mechanism : Paddle type blades welded to the main shaft provide for efficient mixing of thick heavy material. PTFE gland mechanism provided at shaft ends prevents ingress of external powder into the trough and prevents leakage. Charging : From the top charging can be done through hingeable lid, Hopper or Nozzle can be provided for additional spraying of additives. Discharge : By bottom discharge slide Iris or Butterfly valve of suitable diameter, for regulated discharge. Drive : Consisting of suitable HP TEFC 3 phase ac 415v / 50 cycles motor coupled to suitable worm gear, with driving shafts mounted on suitable plummer block. Mounting : Mounted on suitable ISMC Section Stand, with protective covers for belts and couplings. MOC : All contact parts in S.S construction. Complete unit with S.S. cover and all surfaces polished to mirror dull finish. MS parts dull painted to smooth finish. Options Available : The control panel is mounted on platform and is provided. 1.

Best Deals from Powder Mixers

Conta Blender

Get Price Quote

0° stopping for easy docking and undocking of the bin Safety guard around the blender bin Proximity Sensor is provided for safe operation Flexibility of accepting variable bin sizes in single drive unit cGMP Construction S.S. 316 Butterfly valve at the bottom suitable for discharge. Vent nozzle on top Most effective for low volume active ingredient blending with as low as 1 to 1.5%

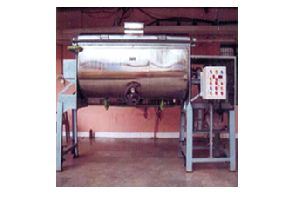

Mass Mixer

Get Price Quote

The Mixer consists of mixing drum complete in itself. It contains a mixing drum body, mixing paddle and sealing arrangement. The drum rests on rigid M.S. fabricated body carrying motor, gear box, starter and tilting arrangement. The drive of mixing paddle is through suitable oil filled worm gear unit which in turn gets drive through V belts from a suitable T.E.F.C. motor. The blades of the paddle are so arranged that thorough mixing is obtained. All parts which are in direct contact with the material to be mixed are of S.S. or neutral material. The main paddle runs in journals and supported by thrust bearings of ample size to carry rigid and thrust load. The whole drum of the mixer makes for ease of cleaning. The rotor is so designed that it can be removed by removing the main shaft without much problem. ADDITIONAL FEATURES: • Plastic Dust Cover provided to see the process all the times. • Safety : If motor covers open it will trop off automatically. • Tilting Device is provided to ease the unloading of the material Specially designed self-adjusting sealing arrangement Provision is made for lubricating all moving parts

Offset Ink Mixing Machine

Get Price Quote

1 Piece (MOQ)

INK Mixing Machine. All fabrication body MS material With SS material vessel (5kg to 100 kg), Gear Box & Branded Motor and VFD Speed Controller.

Double Cone Blender

Get Price Quote

We are offering double cone blender. It is ideal for mixing of powder and homogeneous lubrication of granules. Baffles are provided on central shaft to enhance mixing. Double cone discharge height varies as per the capacities of different models. Suitable manhole for charging is provided with ss-cover & lock nuts.

Ribbon Blender

Get Price Quote

For Continuous Speedy & uniform mixing of dry and semi dry powders Spiral type Ribbon blades for three way mixing. Jacket - Cooling / Heating arrangement available.

Mass Mixer Machine

Get Price Quote

1 Piece (MOQ)

Octagonal Cone Blender

Get Price Quote

The main drum of the Octagonal Blender is coupled to a suitable motor through an oil filled gear box mounted on a sturdy frame structure. The unit is provided with a butterfly valve at one side and is provided with removable baffles inside the drum. The other side is provided with amanhole for accessibility inside the chamber for cleaning. An electrical panel is provided for housing the motor on-off starter, timer, inching device etc. Granulation Line:- Octagonal Blender is coupled to a suitable motor through an oil filled gear box mounted on a sturdy frame structure. a butterfly valve at one side and is provided with removable baffles inside the drum. Salient Features: Due to its unique design lower power consumption at higher loads is possible. Large capacity models are possible due to its compact design. The inside of the blender is completely cleanable through the man hole provided at one side. Also the baffles are removable and can be easily removed for cleaning. Ease in loading through the loading container or through the over head silo or by vacuum transfer is possible. Due to its compact design, lesser floor space required compared t other blenders.

cage blender

Get Price Quote

The cage blenders tumble the in process containers as the preferred method for quick & efficient blending, reducing the number of product exposures point in the process, the material handling & cleaning requirements. Gentle tumbling motion reduces fines creation. Fitted with lid, butterfly & split butterfly valves for dust free loading & discharge.

Ribbon Blender

Get Price Quote

V Blender

Get Price Quote

Ribbon Blender

Get Price Quote

Ideal for Uniform & Homogeneous mixing of dry / semi wet blending & mixing of various materials having different densities provided with various designs of the blades to suit the process requirement. The automatically / manually operated. Used in Pharmaceuticals, Chemical, cosmetics, Foods industry.Capacity ranges – From 10 Liters to 25000 Liters.M.O:- Can be manufactured in all weld able materials, CS, SS, & Special Steel.

Double Cone Blender

Get Price Quote

TECHNICAL OFFER The Double Cone Blender is an efficient and versatile machine for mixing dry powder and granules homogeneously. All the contact parts are made of stainless steel. The effective volume for optimum homogeneity is between 35-70% of gross volume. The SLANT double cone design eliminates dead sports, which occasionally occur in conventional double cone mixer. It can be used for pharmaceutical, food, chemical and cosmetic products etc.Application Dry powder mixing for tablets and capsule formulations Dry granules sub lots mixing to increase the batch size at bulk lubrication stage of tablet granules. Salient Features The conical shape at both ends enable uniform mixing and easy discharge The cone is statically balanced to avoid any excessive load on the gear box and motor While the powder can be loaded into the cone through a wider opening, it can be discharged through a butterfly or slide valve Depending upon the product, paddle-type baffles can be provided on the shaft for better mixing inside the cone. The contact parts are made of either SS 304 or SS 316 Fame proof motor can be supplied as optional Capacity available 20lts.3000 Liters The working capacity can be exchanged to 80% of gross capacity by validated study depending on the product. 'Slant' designed (off centre Double Cone Blender is also available.)

Ribbon Blender

Get Price Quote

Features 1. Blades are designed to suit specified product characteristics. 2. Triple mixing action for fast and efficient blending. 3. Gland packing is provided with Teflon bush and PTFE Braded gland. The Gland can be replaced without dismantling drive assembly.

Paddle Mixer

Get Price Quote

RaviKiran are Manufacturers of Paddle Mixer, ideally suitable for mixing of wet mass, dry powder, dry powder with wet mass, etc, for the preparation of pharmaceutical mass for preparing tablets and similar other applications. The mass mixer gives through mixing due to its unique blade design and the angle of the blade. Granulation Line:- Mass Mixer and Ribbon Mixere ideally suitable for mixing of wet mass, dry powders with wet mass, etc. for the preparation of pharmaceutical mass for the preparations of tablets.

V Blenders

Get Price Quote

V Blenders, Heavy duty gearbox, ploughshare mixers, Sigma Mixers

Double Cone Blender

Get Price Quote

The Double Cone Blender is an efficient and versatile machine for mixing dry powder and granules homogeneously. Salient Features - The conical shape at both ends enables uniform mixing and easy discharge. - The cone is statically balanced to avoid any excessive load on the gear box and motor. - While the power can be loaded into the cone through a wider opening, it can be discharged through a butterfly or slide valve. - Depending upon the characteristic of the product, paddle type baffles can be provided on the shaft for better mixing. - The contact parts are made of either S.S.304 or S.S.316. - Flame proof electricals can be provided as optional. - Capacity available 20 L to 3000 L. - The working capacity can be exchanged to 70 % of gross capacity by validated study. - ‘Slant’ designed (off centre) CLIN CONE BLENDER is also available. - Variable speed option available 70 %. - Cantilever model on request. - Dust free bin charging system on request. Applications - Dry powder to powder mixing for tablets and capsules formulations. - Dry granules sub lots mixing to increase the batch size at bulk lubrication stage of tablet granules. Capacity : 10 Ltrs. to 5000 Ltrs.

Ribbon Mixers

Get Price Quote

We are reckoned as one of the principal Manufacturers and Installers of Ribbon Mixers in India. Horizontal Ribbon Mixers produced by us are ideal for blending of solids, which are less than free flowing. They are designed for fast and effective blending. Our Stainless Steel Double Ribbon Mixers have various specialized features like it has triple mixing actions, limit switches, guards, PTFE Braded gland, etc. In addition to these our ribbon blenders are buffed and ground for smoother and cleaner working. We offer our ribbon blenders in heavy-duty versions, which are used to blend hard solid materials without much effort. Fast and Effective Blending : The Ribbons (Inner and outer) are so arranged that when rotated it reaches each and every corner of the trough and imparts radial and linear motion to the whole of the materials to be mixed. At the same time material is moved from side of the trough to the centre and from the centre of the trough to the sides, resulting in quick and fast homogenising of the product. Blending is achieved in semi fluidised state in the upper zone of the trough when used for fine Powders. Double Ribbon configuration also brings material towards central bottom outlet when discharging. Features Blades are designed to suit specified product characteristics. Triple mixing action for fast and efficient blending. Gland packing is provided with Teflon bush and PTFE Braded gland. The Gland can be replaced without dismantling drive assembly. Guards/Grills and limit switches are provided for maximum operator safety. Blenders are ground and buffed for smooth and clean working. Options Equipments will be fabricated from M.S./S.S.304/SS.316 (GMP/NONGMP). Discharge either by tilting arrangement or through valves and automatic arrangement. Custom built chopper blades. Wireless remote control operation for toxic product. Detachable shaft. Powder loading device with dust free system and transfer. Unit with heating/cooling jacket. Unit suitable for vacuum application. Spray system for liquid addition. Flame Proof electrical equipment.

Double Cone Blender

Get Price Quote

It is ideal for mixing of powder and homogeneous lubrication of granules. Baffles are provided on central shaft to enhance mixing. Double cone discharge height varies as per the capacities of different models. Suitable manhole for charging is provided with SS-cover & lock nuts. Discharge port is fitted with butterfly valve, which helps to unload powder faster. Pipe guards are provided with limit switch & interlocked to motor to ensures safe operation at higher capacity. Optional : Available in STD/GMP models Construction SS 304 / 316 / 316L Butterfly valve for discharge Safety railing for operator safety Variable Speed drive optional Flame proof motor, push button station and limit switch.

Ribbon Blender

Get Price Quote

We offer ribbon blender that is use in varied applications for the purpose of mixing dry granules as well as powders in a homogeneous manner. The ribbon blender that we manufacture is on a huge demand in the market as there is no alternative available to its sturdy construction and effective usage.

Ribbon Blender

Get Price Quote

Double Cone Blender

Get Price Quote

Dies, Punches

dry colour mixers

Get Price Quote

dry colour mixers, plastic processing machines, Dies

V Blender

Get Price Quote

wet granulator, single punch tablet press, Gas Tight Syringe

Ribbon Blenders

Get Price Quote

We are offering best Ribbon Blenders supplying company.

Double Cone Blender

Get Price Quote

We are offering double cone blender.

paddle mixer machine

Get Price Quote

paddle mixer machine, gunning machine, Plastering Machine, Spraying Machine

v cone blender

Get Price Quote

v cone blender, oral processing plant, tablet making plant