Turk's Head Brush - PTH

This design of brush is used mainly for light brushing of all types of tubular plant, including boilers, evaporators, juice heaters, vacuum pans, etc. This is a most popular brush in sugar Mills.

...more

turk head brush

This design of brush is used mainly for light brushing of all types of tubular plant, including boilers, evaporators, juice heaters, vacuum pans, etc. This is a most popular brush in sugar Mills.

...more

Tube Expansion System

The Digital Torque Control Unit is built to operate four types of driving units PD-0, PD-1, PD-2 & PD -3 The drive is a conventional electric drill type machine. The characteristic of the unit is such that the current drawn by the motor increases as the load is applied and by the accurate measurement of this current the effort produced is determined and also the degree of tube expansion, when the preset torque is reached.

...more

Tube Expansion Machine

The Digital Torque Control Unit is constructed from most modern components, to provide an accurate means of controlling the amount of current supplied to the driving unit so that the torque can be regulated. The Digital Torque Control Unit will automatically switch off the drive unit as soon as the drive current reaches a preset value of expansion or torque has been attained. The digital readout allows precise setting to the exact torque required.Features : Eliminates over rolled and under rolled tube joints Increases production - reduces costs Release skilled employees for more precise work

...more

tube expanding machines

tube expanding machine

We are offering tube expanding machine..this specification are:- Model Powerflex Torque Control Unit Input Electrical 3 Phase, 415V+- 10%V Electric Motor 3.7 KW 5 HP, 1430 RPM, 5060 Hz Control Voltage 24V DC Max. Working Pressure 100 BAR Maximum Flow 23 LPM Oil Tank Capacity 45 LTR

...more

Tube Expanding Equipment

The Tube Expanding Equipment we deal in is built using the most modern technology. Our Tube Expanding Equipment is enabled to impart an accurate means of controlling the amount of current supplied to the driving unit so that the torque can be regulated. We have advanced facility for the fabrication of Tube Expanding Equipment and the entire procedure is completed in compliance with industry set norms and quality standards.Details : The Digital Torque Control Unit is constructed from most modern components, to provide an accurate means of controlling the amount of current supplied to the driving unit so that the torque can be regulated. The Digital Torque Control Unit will automatically switch off the drive unit as soon as the drive current reaches a preset value of expansion or torque has been attained. The digital readout allows precise setting to the exact torque required. The Digital Torque Control Unit is built to operate four types of driving units PD-0, PD-1, PD-2 & PD -3 The drive is a conventional electric drill type machine. The characteristic of the unit is such that the current drawn by the motor increases as the load is applied and by the accurate measurement of this current, the effort produced is determined and the degree of tube expansion, when the preset torque is reached. Features : Eliminates over rolled and under rolled tube joints Increases production - reduces costs Saves the need of skilled employees Assures uniformly rolled tube joints Reduces need for constant inspection

...more

Tube Expanders

These 'tp' & 'tf' series tube expanders are widely used for smooth and accurate expansion of tubes in boilers, economisers, super heaters, juice heaters, evaporators etc. the there roller 'tp' series tube expander is a fixed roller length, parallel rolling tool. the 'tf' series tube expander is provided with one additional belling roller to flare tube projection. The chart provided below is for quick easy selection of the correct tube expander. The last digit of tool number denotes plate/drum thickness. The standard tube plate thicknesses are 30 mm(3), 40 mm(4), 55 mm(5), 65 mm (6). tube o.d.× tube wall thickness (t), and wall thickness tolerance. tube sheet thickness (t), and effective expansion length required. when requiring flare expansion, flare angle (α) and tube projection (p). hand hole diameter of header. length of straight tube part (s). curve radius of bent tube part (r). type of expander (tp, tf etc.) type of mandrel required.

...more

Tube Expander Accessories

Our Company is one of the most trusted Manufacturers, Exporters and Suppliers of Tube Expander Accessories. We design various equipment needed for the expansion work, like ratchet handle, gear block, drive shaft, expander oil, expander cream, extension bar, etc. We lay utmost preference over quality, thus our Tube Expander Accessories are made of top quality materials. Moreover, we provide Tube Expander Accessories at very competitive prices.

...more

tube cleaning system

Powerflex Tube cleaning system with water feeding attachment for wet application in condenser & cooler tubes. Features : Operates on single phase supply which is easily available Water flows through the shaft. It softs the scale & flushes out from the tube Tube cleaner is operates by foot. So operator concentrate on cleaning operation Flexible shafts are easily connected & disconnected Moblie trolley for easy movement Water flows through the shaft when operator press the foot pedal

...more

Tube Cleaning Machine

Tube Cleaning Machine, offered by us, is electrically operated and is used for cleaning straight and curved tubes in boilers and process plants. Our Tube Cleaning Machine has robust construction and hence is easy to use even by new workers. The Tube Cleaning Machine requires minimum maintenance and imparts a hassle free service. The price of the high performance machine is also very competitive.Features : It consists of a TEFC, continuously rated, squirrel cage, 400/440 volts, 3 phase, 50 C/S, A.C. electric motor. Self-contained portable unit mounted on 3-wheel trolley, fitted with a lifting or carrying handle. The motor H.P. and speed according to choice. (Standard machines with H.P. 3, 5 & 7.5 and speed 2880 or 1440 R.P.M.). It is controlled by a push button starter, which also embodies single phasing protection (3 phase).

...more

Tool Head Cutters

Tool Head Cutters are widely used for tube de-scaling of pipes, juice heaters, boilers and vacuum pan tubes. The design of our Tool Head Cutter is simple, thus it can be easily used by non-experts as well. The equipment is extremely efficient as it increases the de-scaling speed and prevents grooving of the scale. Tool Head Cutters are highly recommended for use when the scale in the tubes is medium to hard.

...more

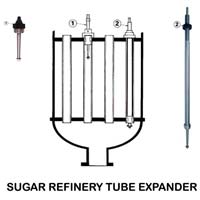

Sugar Refinery Tube Expander

The function of TUBE EXPANDER is to make a good mechanical seal between tube and tube sheet. Powerflex Tube Expanders do this by means of a set of rotating, parallel rolling and self feeding rollers, which cold work the tube joint metals until the tube ends fit tightly in the holes in the sheet. Powerflex Tube Expanders give smooth, accurate expansion and perfect tightening of joints with no surface ridging. The very best materials are selected and production quality is carefully checked at every step of manufacturing. The result is a product of complete dependability.

...more

Single Speed Machine

Electrically operated for cleaning straight and curved tubes in Boilers and process plants. Powerflex flexible shaft machines are of robust construction, simple to operate by unskilled workmen and will give trouble free service with minimum maintenance. It is a self-contained portable unit mounted on 3 wheel trolley, fitted with a lifting or carrying handle. It consists of a TEFC, continuously rated, squirrel cage, 400/440 volts, 3 phase, 50 C/S, A.C. electric motor. The motor H.P. and speed according to choice. (Standard machines with H.P. 3, 5 & 7.5 and speed 2880 or 1440 r.p.m.) It is controlled by a push button starter, which also embodies single phasing protection (3 phase), as well as overload and under voltage protection. In addition it is also ambient temperature compensated. Each machine is fully wired, carefully tested and is fitted with a 20 feet length of PVC cable to the main supply.

...more

Ratchet Handle

This is a manual tube expansion tool. It allows rotational transmit by a ratchet mechanism.

...more

Powerflex Swing Frame Tool Head - PSL

This model is a swing frame cutter head and therefore has a large expansion-contraction range. It is fitted with 3 to 5 cone cutters (depending on size) to break up heavy shoulders of scale and long lines of star cutter wheels for thorough cleaning of remaining scale in one pass. It is supplied with an adaptor for straight tubes and universal joint for curved tubes.

...more

Powerflex Spring Loaded Tool Head - PSL

This spring loaded, self expanding, tool head is fitted with fifteen cutter wheels, five each on three bridge type arm pins and is slightly tapered at the top end. While the tapered top allows easy entry in the tube, the spring loaded arms allow the cutter wheels to contract or expand according to scale conditions.

...more

Powerflex Single Head - PSH

Designed for general tube descaling of process pipes, boiler, juice heater and vacuum pan tubes. The design of this head is simple and its action is extremely effective. These cutter heads are fitted with 3 cutter wheels one each, teeth cut straight, teeth cut right and teeth cut left, which increase descaling speed and prevent grooving of the scale. The side plates are reversible and double drilled to give maximum length of service.

...more

Powerflex Pivoted Arm Tool Head - PPA

This tool head is for hard-to-get-at medium to extra thick deposits ranging from gummy to hard. Four cone cutters fitted on arms of unequal length are pivoted at the spider on the rear of the cutter head, which gives maximum tube cleaning range. It is supplied with an adaptor for straight tubes and universal joint for curved tubes.

...more

Powerflex Carbide Drill Head - PCD

Designed for cleaning fully or partially blocked tubes of soft or hard deposits. The cutting edges are tapered to a point to enter small openings. The drill roughs out the deposit and is generally followed by use of a cutter head. It is supplied with an adaptor for straight tubes and universal joint for curved tubes.

...more

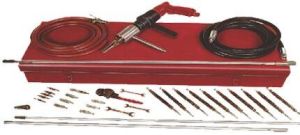

Portable Tube Cleaning Kit

Portable Tube Cleaner is designed for cleaning straight tubes in condensers, coolers, chillers etc. These exchangers contain many small diameter tubes which vary from 3/8" to 11/4" in diameter and six to twenty feet in length. A tool head is fed into the tube on a rigid hollow shaft. The hollow shaft and tool head are turned by a portable drive handled by an operator at one end of the exchanger. Standard length of shafts are connected using couplings to clean required length of tube. A water flushing system is attached to the drive. A stream of water conducted along the hollow shaft flushes loose deposits out of the tube and keeps the tool head cool. Water flow and air drive are controlled independently eliminating excessive water consumption and mess. The use of one piece shaft is preferable where sufficient head room prevails. Features : It's powerful portable cleaner for totally chocked tubes Water flows through the shaft. it softs the scale & flushes out from the tube. Water flows through the shaft when operator press the water gun trigger. Hollow drive shaft & hollow driven shaft can coupled together with shaft coupling to for the Required length of the tube which is to be clean.

...more

Tube Cleaning Kit

Tube Cleaning Kit is used for cleaning straight tubes in condensers, coolers, chillers etc. The specially designed Tube Cleaning Kit is ideal for completely chocked tubes. We deal in a range of Tube Cleaning Kits that are made of several small diameter tubes with sizes ranging from 3/8" to 11/4" in diameter and six to twenty feet in length. We are one of the leading Manufacturers, Exporters and Suppliers of Tube Cleaning Kit in Vasai, Maharashtra.Features : Water flows through the shaft. It softens the scale & flushes out from the tube. Water flows through the shaft when operator presses the water gun trigger. Hollow drive shaft & hollow driven shaft can be coupled together with shaft coupling for the required length of the tube, which is to be cleaned.

...more

Outer Casing Round Or Interlock Design

Flexible shaft is a complete mechanism capable of transmitting rotary power from the motor unit to the tool head or brush within the tube. The size of the flexible shaft is based on internal diameter (ID) of the tube. Inner wire core is flexible shaft's most important working element. It is designed and constructed to meet power drive operating conditions that include torque, speed, length and minimum bend radius. At the centre of the core is a single wire around which successive multi-stranded layers of wire are wrapped. Each layer is wound in the opposite direction and at right angles to the layer directly beneath it. The direction in which the wire on the outer most layer is wound determines the direction in which the shaft is designed to rotate. Outer casing made of galvanized steel / rubber hose and internally reinforced with antifriction lining to support the wire core and resist helixing under torque loading. It does not rotate and it functions as a cover to protect the core. Handpiece is attached to one end of the shaft, either detachable or fixed type, with threaded spindle to connect tool heads or brushes, with two nos ball bearing. Motor coupling is fitted to the other end of the shaft, either threaded type or pin type. The length of the flexible shaft required is the addition of the length of the longest tube plus the distance between the mouth of the tube and the position of the power unit.

...more

Multi Speed Machine

Powerflex flexible shaft machines are of robust construction, simple to operate by unskilled workmen and will give trouble free service with minimum maintenance. It is a self-contained portable unit mounted on 3 wheel trolley, fitted with a lifting or carrying handle. It consists of a TEFC, continuously rated, squirrel cage, 400/440 volts, 3 phase, 50 C/S, A.C. electric motor. The motor H.P. and speed according to choice. (Standard machines with H.P. 3, 5 & 7.5 and speed 2880 or 1440 r.p.m.) It is controlled by a push button starter, which also embodies single phasing protection (3 phase), as well as overload and under voltage protection. In addition it is also ambient temperature compensated. Each machine is fully wired, carefully tested and is fitted with a 20 feet length of PVC cable to the main supply.

...moreBe first to Rate

Rate ThisOpening Hours