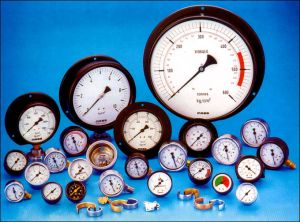

Weatherproof Bourdon Type Pressure Gauges

"MASS", Weatherproof gauges are commonly used in Chemical Processing, Petroleum Refinery, Petrochemical, Fertilizer, Thermal & Nuclear Power generating industry & process applications.

Dial Size : 65mm, 100mm, 150mm & 250mm

Accuracy : + - 1% of F.S.D

Thread Connection : 1/8", 1/4", 3/8", 1/2" BSP/BSPT/NPT (M)

...more

Weather Proof Pressure Gauges

"MASS", Weatherproof gauges are commonly used in Chemical Processing, Petroleum Refinery, Petrochemical, Fertilizer, Thermal & Nuclear Power generating industry & process applications. Mounting Direct with bottom EntryDirect with back entryFlush Panel with back entry(Three hole panel or bracket type)Surface with bottom entry,Joints S.S. Bourdon tube tip and the socket ends are ARGON ARC WELDED and phosphor bronze bourdon tubes are silver brazedsoldered. Bourdon tubes are heat-treated and stress relieved,Extra Fitments Micro Zero Adjustment Pointer Neoprene blow out disc.

Dial Size : 65mm, 100mm, 150mm & 250mm

...more

Valves and Compression Tube Fittings

'MASS' tube fittings were developed in response to industry demand for an alternative ultra high quality double ferrule instrumentation grade fitting. All 'MASS1 tube fittings are engineered and manufactured to withstand the severest service conditions while providing the ultimate in sealing capabilities and reliability in varied system services from cryogenic to steam, Vacuum to tubing yield pressures. 'MASS' make single and double compression tube fittings provides leak proof joints at all tubing connection, this eliminates leakage. 'MASS' Needle valve is made from single piece forged body or bar stock construction. 'MASS' instrument Ball valves is very compact and low torque design. Our Capabilities : The 'MASS' group is a world leading manufacturer of high performance ball and needle valve with an unrivalled reputation for innovation, product development, quality and service. With a rapidly expanding manufacturing facility at Chhatral near Ahmedabad (Gujarat) and a comprehensive network of marketing and distribution outlets across the globe. The company is able to offer outstanding support to our customers worldwide TOTALLY "INTERCHANGEBLE" WITH SWAGELOK Construction and Operation : 'MASS' tube fittings are composed of four precision-machined parts: 1) Body, 2) Front ferrule, 3) Back ferrule, 4) Nut. A leak-tight seal is achieved through the simple action of tightening the nut against the nut body. The geometric rotation of the nut provides the axial thrust required to compress the captivity-held ferrules against the outside diameter (O.D.) of the tubing. The staged swaging action of the ferrules during the compression phase of make-up provides the key to sealing superiority.The front ferrule as it is urged forward against the tapered area of the body is forced inward, thus gripping and subsequently sealing the leading edge tightly on to the tubing. Simultaneously the back ferrule, dove tailing directly behind the front ferrule, swages beneath its trailing edge affording the desired coining action the mechanical connection of tubing and fitting. It is this interaction offer rules that allows to achieve its excellent sealing capabilities under a wide variety of application variables. ADVANTAGES For 'MASS' Single And Double Compression Tube Fitting All fittings shaped out of high quality forging. Double ferrule swaging action. Self-alignment. No transfer of torque to tubing. Compensating seal action to accommodate temperature and pressure variations. Universal tubing compatibility. Low torque, high purity "Silver" thread coating on nut. Minimum flow restriction. Will not weak on tube wall. Fittings are tested for high pressure Hydraulic, Pneumatic, Impulse, Vibration and Temperature to ensure safety and leakproof joints. Size range:-1/16"to2"and 3mm to 50mm. Material of construction Stainless Steel of all grades and all special materials. For 'MASS' Needle Valves Single piece forged body or bar stock construction. Union bonnet or screwed bonnet connection Metal to metal or stellited seat for high pressure, Teflon seat for low density gases and non lubricating fluids. Hard plated or stellited tip, non-rotating tip steam. Teflon seatorGrafoil packing for bubblefreejointat various temperature. Variety of end connection includes 1/8" to 1"OD single and doubleferrule fittings, 1/8" to 1" Male, Female, NPT,SP,JIS, ISO and din pipe ends. Optional bleed plug provided for drainage of residual fluid. Pressure range: 3000-10000PSI at 120 500 degree centigrade Din valve for European standard For 'MASS’ Ball Valves 'MASS' ball valves are very compact, low torque design with panel mounting facility Two way ON-OFF service, Three and four way for switching of the stream & Five way for selection of the stream All valves are made in SS and Brass in sizes 1/4",3/8" and 1/2" NPT, BSP, SW and BW male and female

...more

Utility Pressure Gauges

MASS make Utility Pressure Gauges are available in 40, 50, 63, 80, 100, 150 & 250mm dial size. These are specially designed for valve positioners, airfilters & regulators, small boilers, fire extinguishers, pharmaceutical & food processing equipments, pumps, compressors, hydraulic & pneumatic systems, ammonia & refrigeration services. Quality Control features carried out on each gauge. Leak test -Overload test - Calibration and Accuracy test - Hyteresischeck -Thread check by ring gauges - Visual Inspection of finishing of internal components, dial printing, paint of dial & casing, entire assembly of gauge & final packing for shipment.

...more

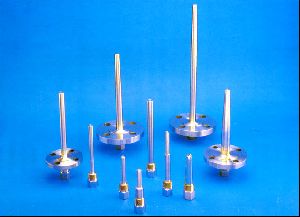

Thermowell For Sensors and Temperature Gauges

MASS' make thermowells are design to protect the temperature gauges from various corrosive media, Pressure, Viscous material or Velocity and abrasive's. A thermowell design permits quick removal and easy fitment of thermometer for replacement, repair and testing.'MASS' thermowell features welding neck or screwed connection from solid bar construction to fit standard stem length. 'MASS' can give thermowells in straight, tapered, stepped and standard flange construction. 'MASS' make thermowells are widely used for Bi-metal, Mercury, Gas filled thermometer, sensors and different application like Pulp and Paper industries, Food and Beverage industries, Machine and Apparatus construction, Chemicals, Petrochemicals, Fertilizers, Refineries, Pharmaceuticals and National Thermal Power Stations.

...more

Test and Master Pressure Gauges

MASS make Master Gauges are designed for use as a reference gauge for recalibrating general service gauges, transmitters and other pressure operated instruments.These gauges are easy to carry for field use and for spot inspections. To make reading easier and faster each pressure gauge is provided with readble dial. Reading error caused by paralax is eliminated by aligning the knife edge tip pointer with its reflection in the mirror band on the gauge.

Connection : 1/2"NPT(M)/BSP(M)

...more

Single Diaphragm Differential Pressure Gauges

MASS1 make differential pressure gauges are used to measure the pressure difference between two lines. Which can be directly indicated on dial. For ranges up to 6000 mmWC Max. Static pressure is 25kg/cm2 and for ranges 1 kg/cm2 to 10kg/cm2 Max. Static pressure is 40kg/cm2.'MASS' make differential pressure gauges are suitable for Noncorrosive and Noncrystallizing gaseous and liquid media and that are not highly viscous.'MASS' make differential pressure gauges are widely used across the Filters for Liquid control systems, Pharmaceutical industries, Chemicals, Petrochemicals, Fertilizers, Refineries and all Process industries

Dial Size : 115mm & 150mm

Accuracy : + - 2% of full scale

Operating Temperature : -25 to 65°C Max.

...more

mercury filled temperature gauges

'MASS' make mercury filled temperature gauges are made of a sensor bulb, transmitting capillary and a special flat bourdon tube, which are pressure-filled with mercury. As temperature changes the bulb will change the pressure in the system and indicated on the scale, calibrated in temperature units. A Bi-metal device is connected to the bourdon tube to compensate for temperature error due to variation in ambient temperature. Mercury filled temperature gauges measures from 38C to 600C with an accuracy class of+1% of full scale.'MASS' make mercury filled gauges are economical, rugged, reliable and accurate measuring instruments available in different dial sizes, connection, mounting with different type of capillary with different length (maximum up to 25m). Mercury filled temperature gauges are also available with accessories like Antivibration spring, Electrical contact, Gauges with Glycerin or Silicon oil filled and with thermowells.

...more

Mercury Filled Temperature Gauge

'MASS' make mercury filled temperature gauges are made of a sensor bulb, transmitting capillary and a special flat bourdon tube, which are pressure-filled with mercury. As temperature changes the bulb will change the pressure in the system and indicated on the scale, calibrated in temperature units. A Bi-metal device is connected to the bourdon tube to compensate for temperature error due to variation in ambient temperature. Mercury filled temperature gauges measures from 38C to 600C with an accuracy class of+1% of full scale. 'MASS' make mercury filled gauges are economical, rugged, reliable and accurate measuring instruments available in different dial sizes, connection, mounting with different type of capillary with different length (maximum up to 25m). Mercury filled temperature gauges are also available with accessories like Antivibration spring, Electrical contact, Gauges with Glycerin or Silicon oil filled and with thermowells.

...more

Low Pressure Diaphragm and Capsule Gauges

Diaphragm gauges are suitable for measuring pressure of all kind of fluid and gaseous medium. The measuring element is a sensitive corrugated diaphragm fixed between two flanges. For slurry and viscous liquids flanged connections can also be incorporated. Low Pressure Bellow Capsule Gauge are designed for non-corrosive and non-aggresive application.These Gauges have bellow capsule which is composed of two corrugated metal discs of Brass / Stainless Steel joined by brazing / argon arc welding. A rise pressure will cause the corrugated Capsule / Diaphragms to expand and this motion is transferred to the indicator through sector, pinion movement mechanism. A similar type of low pressure built-in capsule gauge can also be offered having almost similar kind of mechanism.

Accuracy : 11.5% and+2% of the f.s.d.

Connection : 3/8M/2-BSP/NPT. T type flanges & Direct Flanges. As per ASA, ANSI, BS & DIN Standard.

Range : -760 mmHg Vaccum and up to 21 Kg/sq.cm for diaphragm type " D " model & from 250mmwcUpto 10,000 mmwc for low pressure diaphragm type " LPD " model.

...more

Hygienic Diaphragm Seals

'MASS' make diaphragm sealed gauges are designed for systems needing contact surface that are rigorously cleanedand totally safe. The function of diaphragm is to isolate the pressure gauge from the process fluid, preventing bacteria developing inside pressure gauges sensing element. The advantage of the flush diaphragm gauges is easy to clean and quick release coupling. The following connection systems can be provided. 1. Triclamp systems.2. SMS with union nut and SMS with male thread.3. Homogeniserwithflange.

...more

glycerine filled pressure gauges

Provides Extra Margin of Protection from Vibration and Pulsation. 'MASS1 make Glycerine Filled Pressure Gauges are installed on Powerpacks, Hydraulic Machinery, Pumps, Compressors, Power Plants, Pipelines and Transmission Stations where Vibration & Pulsation are destructive factors. Glycerine filling makes the difference, the movement is submerged and constantly lubricated. The damaging effect of pulsation and vibration are minimised Pointer flutter is virtually eliminated because both the liquid filling and a restrictor screw in the Socket help in dampening pulsation.

...more

Electrical Contact Pressure Gauges

MASS Make SingleDouble Snap action Magnetic Eletrical Contact Gauges are available in 100mm & 150mm dial size. These gauges serve for the measurment and control of pressure by switching 'on and off electrical equipments. Thus eliminates the need of separate switches for equipments such as pumps, motors, turbines, blowers for audiovisual alarms for signalling irregularities. These Contacts may be used under almost all operating conditions, they are largely immune to vibration. The contact pin carrier of the indicator is equipped with an adiustable magnet which attracts the contact arm just prior to reaching the indicator. This prevents arcing and burning of contact pins.

...more

Diaphragm Sealed Pressure Gauges

MASS make Diaphragm Sealed Pressure Gauges are designed to measure the corrosive fluids pressure, where suitable material for bourden tube is not available.The Diaphragm assembly withstand various corrosive actions encountered and seals the Bourdon tube from the process fluid. The displacement of the liquid filled in the Bourdon tube, through movement of the diaphragm, transmits the process pressure to the gauge. The Diaphragm sealed connections are available with threaded type, flanged type and capillary type mountings. ifferent type of Chemical Seals can be provided such as : Flange-type diaphragm seals Cell-type (sandwich) diaphragm seals Flange-type seals with extended diaphragm With hygienic-type connection- SMS standard- Tri clamp fitting Pulp and paper industry design High pressure diaphragm seals, homogeniger flange Welded body, male thread Capsule-Type Chemical Seals

...more

Bellow Differential Pressure Gauges

The pressure element of these instruments has two S.S.316 bellows, balance mounted. The value shown on the dial is the difference between two input pressure or depressions coming in to each bellow. 'MASS' Differential Pressure Gauges are entirely made of S.S.316 wetted parts, therefore they offer the same corrosion resistance (inside and outside) as the Bourdon Pressure Gauges. Moreover the mechanical resistance of the bellows allows important one-sided overpressure, compare to the differential pressure (up to 20 times in some cases). All differential pressure gauges are used for measurements of flow, level, filter clogging, pressure drop measurement, air conditioner & chemical processor. Optional Features : Adjustable micrometer pointer Window Plexiglass or safety glass Anti vibrations filling liquids. Glycerin or silicone oil. Oil free manometric parts for oxygen service. Special threaded or flanged connection. Other dial graduations: linear, square root, flow, level, '0' at center. Electric contacts. Diaphragm seals of different materials.

Dial Size : 150mm

Accuracy : ± 2% of full scale / ± 1.6% of full scale

...moreBe first to Rate

Rate ThisOpening Hours