Tray Dryer

High Efficiency Axial Flow Fans mounted at most appropriated places in the dryer plays an important part in faster drying and provides uniform air circulation withinthe dryer. Axial flow fans are mounted externally on ball bearing pedestals and each fan is driven by independent1 HP TEFC motor. Air inlet and exhaust outlet dampers are provided on the top roof of the dryer.Insulation :The cavity formed in between double wall is heavily insulated with glass wool on all the sides to prevent heat losses from the Dryer.Control Panel : Pre-wired control panel consists of digital temperature controller, over current relays, fuses, indicating lamps, push buttons, main isolator switch etc.

...more

Octagonal Blender

Our range of octagonal blender are used for quick and efficient mixing. The machine have the capacity to mix up to 4000 ltrs. The machine have an program operating system, which is very much user friendly.

...more

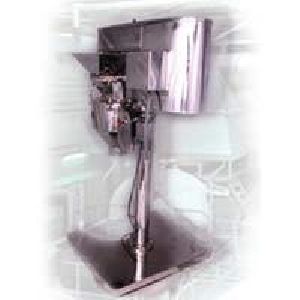

multi mills

Multi mills and industrial multi mills is commonly used in pharmaceutical industries. The beaters and scrapper blades are two important parts of this machine, which are made up of stainless steel. Salient Features :• Multi mills and industrial multi mills are widely used for wet and dry granulation, shredding, pulverization etc. in pharmaceutical, chemicals and other industries.• Standard and lab models available.• GMP/ Flameproof/ SS 316 construction on demand.• Direction of beaters can be changed by reversible switch.• All contact parts can be easily and quickly dismantled and cleaned.• Machine is designed for continuous operation.• Cylindrical screen for higher output.• Castor provided for ease of mobility.• Beaters and scrapper blades of SS 410 quality are hardened and polished to mirror buff.

...more

Industrial Flaker

The Pragati Enginnering Works offers flaker, industrial flaker, chemical flaker, flaker machines to convert molten chemical in to solid flakes. This is achieved by forming a thin layer of molten product on the outside surface of a rotating drum and causing this to be solidified by spraying cooling water from inside surface of the drum. An adjustable scrapper continuously removes the solidified from the drum surface in flake forms. The material of construction for the drum can be mild steel,Stainless Steel with / with Hard Chrome Plating, normally Monoblock for weldable materials. This construction ensure lifelong alignment, surface will be machined and ground finished. Drum Rotating on antifriction self aligning ball / roller bearing with standard Housing. Heavy duty drive arrangement for smooth, continuous and trouble free running. V-Pulley or Variable speed arrangement also provided for optimum performance. The Flaker Machine will be complete with 1440 RPM, 3 Phase, 415 volts, TEFC / ISD motor, with gear box, Tray, Hopper, M.S. hood, Belt Guard. Machine mounted on heavy base-plate for trouble free service. It’s optional features is Screw Conveyor, Flaker Breaker, Film thickens controllers, Complete enclosure for Hazardous application. Company also providing pilot unit which is available for, to take running trial on receipt of sample about 15 Kgs. Company carries out the test on it, to produce reliable information’s on outputs and for the scaling of purpose. Flaker used inAcetanilide, Fatty acids, Monochloro acetic acid, Nickel catalyst, Naphthalene, Resin, Waxes and so many other products. Special Features:• Designed for trouble free operation• Low Cost operation• Continuous Process• High thermal efficiency• Minimum thermal degradation• Accomplishment of flaking in a single step• Uniformly flaked product

...more

Fluid Bed Dryer

• Single piece construction- without flange joints.• Complete dryer have stainless steel construction with mirror polished product contact surfaces.• Edges of all the parts rounded off and only butt welding carried out (by argon arc process).• Filters bag sealing arrangement by means of inflatable tube.• Interlocking between filter bag sealing tube and blower motor, and exhaust butterfly valve.• Product container lifting platform and air cylinder replaced by pneumatically operated gasket.• Rapid change of filter bag.• Built to suit GMP regulations

...more

Drum Flaker

The Pragati Enginnering Works offers flaker, industrial flaker, chemical flaker, flaker machines to convert molten chemical in to solid flakes. This is achieved by forming a thin layer of molten product on the outside surface of a rotating drum and causing this to be solidified by spraying cooling water from inside surface of the drum. An adjustable scrapper continuously removes the solidified from the drum surface in flake forms. The material of construction for the drum can be mild steel,Stainless Steel with with Hard Chrome Plating, normally Monoblock for weldable materials. This construction ensure lifelong alignment, surface will be machined and ground finished. Drum Rotating on antifriction self aligning ball roller bearing with standard Housing. Heavy duty drive arrangement for smooth, continuous and trouble free running. V-Pulley or Variable speed arrangement also provided for optimum performance. The Flaker Machine will be complete with 1440 RPM, 3 Phase, 415 volts, TEFC ISD motor, with gear box, Tray, Hopper, M.S. hood, Belt Guard. Machine mounted on heavy base-plate for trouble free service. It’s optional features is Screw Conveyor, Flaker Breaker, Film thickens controllers, Complete enclosure for Hazardous application. Company also providing pilot unit which is available for, to take running trial on receipt of sample about 15 Kgs. Company carries out the test on it, to produce reliable information’s on outputs and for the scaling of purpose. Flaker used in Acetanilide, Fatty acids, Monochloro acetic acid, Nickel catalyst, Naphthalene, Resin, Waxes and so many other products.

...more

Drum Dryer

The feed stock is introduced into a singleor twin steam heated drum dryer in a uniform film by use of variety of feeding devices and arrangements depending upon the material to be dried. The moisture is dried off in less than one revolution and the dried solid is removed usually in the form of a thin sheet/powder by doctor blade.Advantages:• Minimum Thermal degradation• High thermal efficiency• Fine and spheroidal product• Minimum labor requirements• High output• Continuous process• Accomplishment of drying in single step,eliminating need for any intermediate concentration processes.

...more

Double Cone Blender

• For gentle and diffusive blending of dense powders suitable for blending of large batch volumes in a short time. • Easy and dustless operation. • Model available 25 kgs. to 500 kgs. cap. • GMP/Flameproof/ SS 316 Construction on demand. • Provided with inching arrangement and Limit switch on demand. • Macon/butterfly valve provided for quick discharge for higher cap. Model. • Steam jacketed model available on demand.

...moreBe first to Rate

Rate ThisOpening Hours