Tubular Manifold Heaters

5 Piece(s) (MOQ)

We are offering tubular manifold heaters. Description: also known as formed tubular heaters or flexible heaters, these heaters are mainly used for hot runner manifolds. Php manifold heaters are designed and manufactured with 40 years of experience, for superior performance and life expectancy to withstand high sheath temperature and provide the best combination of physical strength, high emissivity & good thermal conductivity to heat hot runner manifolds. A superior grade of helical wound high temperature resistant nicr alloy heating wire is swaged in chrome nickel steel sheathed tubes. The insulation consists of superior grade of magnesium oxide (mgo). Threaded terminal post which gives a cold section of approx 40mm (min) are sealed with special sealing components to prevent the heater from moisture. These are then formed to shapes as required to press fit in the hotrunner manifold which dissipated even heat transfer to the hotrunner mould. For manufacturing manifold tubular heaters it is necessary to provide an accurate dimensional sketch showing all centre distances, bending radius and path. application: hot runner manifolds features: 1 ce certified. 2 available in chrome nickel steel 3 available in dia 8mm, 8.5mm, 6.5mm & square section 6mm x 6mm 4 sealed edges to prevent from moisture 5 superior grade magnesium oxide insulation 6 swaged for good electrical insulation & even heat transfer.

...more

Saving Insulated Jacket

Feature : Non-Flammable Reusable Covers, Multilayer Design, Corrosion Resistant

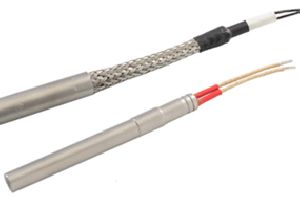

micro tubular heaters

5 Piece(s) (MOQ)

We are offering micro tubular coil heaters are designed and manufactured with 40 years of experience, for superior performance and life expectancy. Depending upon applications, these heaters provides the best combination of physical strength, high emissivity and good thermal conductivity to heat hot runner bushing nozzles mainly for multi cavity hot runner pet perform moulds and thin wall container moulds. axial clamp the 1.8 mm diameter micro tubular heater is formed into a coil of predefined dimension and equipped with a special cover for easy fitment. This special cover called axial clamp allows front end loading and adjustability. Such easy handling saves hours of downtime in case of heater failure in a multi - cavity mold. These heaters are offered with staggered cold leads of 5" and 7". applications: 1. pet preformed moulds 2. hot runner nozzles & bushings 3. thin walled container moulds features: 1. ce certified. 2. standard size available id 19mm x 30 & id 22mm x 30 3. faster heat transfer with flat cross section tube (1.40mm x 2.20mm) 4. two standard diameters, 1.5 mm and 1.8mm (0.059" & 0.07") 5. standard wattage available 149 watt & 268 watt on 240 volt 6. staggered cold leads of 5" and 7" 7. robust construction in micro tube dia - 1.50 & 1.80mm 8. equipped with a special cover for easy fitment over circular parts. 9. axial clamp - front end loading adjusting saves hours of downtime in moulds.

...more

Micro Tubular Coil Heaters

Clients can avail from us Micro Tubular Coil Heaters, designed with 40 years of experience, for superior performance and life expectancy. Micro Tubular Coil Heaters that we offer provide the extreme physical strength, good emissivity & excellent thermal conductivity to heat hot runner bushing / nozzles primarily for multi cavity hot runner PET perform moulds & thin wall container moulds. These heaters can be availed with staggered. We offer 1.8mm diameter Micro Tubular Heater that is formed into a coil of predefined dimension and is equipped with a special cover for easy fitment. Attributes : CE Certified Staggered cold leads of 5 & 7 Faster Heat Transfer with flat cross section tube (1.40mm x 2.20mm) Standard wattage available 149 watt & 268 watt on 240 volt Robust Construction in Micro Tube Dia 1.50 & 1.80mm Standard size available ID 19mm x 30 & ID 22mm x 30 Two standard diameters, 1.5 mm and 1.8mm (0.059 & 0.07) Equipped with a special cover for easy fitment over circular parts Axial Clamp - Front end loading / adjusting saves hours of downtime in moulds Applications : Thin Walled Container Moulds PET Preformed Moulds Hot Runner Nozzles & Bushings

...more

micro coil heater

Faster Heat Transfer with flat cross section Two standard diameters, 1.5 mm and 1.8mm tube (1.40mm x 2.20mm) (0.059” & 0.07”) Standard wattage available 149 watt & 268 Staggered cold leads of 5” & 7” watt on 240 volt Std. size available ID 19mm x 30 & ID 22mm x 30 Robust Construction in Micro Tube Dia – 1.50 Equipped with a special cover for easy fitment & 1.80mm over circular parts Axial Clamp - Front end loading adjusting saves hours of downtime in moulds

...more

Mica Strip Heaters

PHP Mica Strip Heaters offered by us are high on demand in the market. The Mica Strip Heaters offered by us offers superior performance and higher life expectancy. These heaters are good for sheath temperature up to 250 C. The strip Heaters are available with various construction styles with various lead exit options. Also, clients can be benefited from the availability of Mica Strip Heaters at the competitive prices. Applications : Sealing EquipmentDie, Mould & other surface HeatingHot stamping, Hot PlatesFor use where surface contact on both side of heater if necessary Post Terminal Dimension And Location : Post Terminal are located 1/4" from edge of heated section either vertical , parallel or at opposite endsMounting holes may be located anywhere on the heater as long as there is minimum of 1" between the edge of the hole and one side of the heater Options Available In Mica Strip Heater : S/S braided leads for flexibilityCustom mounting holesCeramic terminal coversSingle & Two Phase voltage Construction Mica Strip Heater - Fiberglass Leads :Fiberglass leads out same end center :10� lead standardLeads rated to 850oFLeads out same end edge :1/2" Sleeving at exitLeads out opposite end :1/2" Sleeving at exitLeads out at the top of heater :Brass eyelet where leads exit sheath1/2" Sleeving at exit

...more

mica strip

PHP’s Mica Strip Heaters are manufactured as per customer’s specifications in various sizes with high temperature sheathing materials and high grade mica insulation for higher temperatures upto 450 0 C. Evenly wound high grade NiCr resistance wire is used for uniform heat distribution and long life. These are available in many Termination Styles and can accommodate holes and cutouts. (Maximum Temperature 4500 C)

Length : Minimum 65 mm

...more

Mica Nozzle Heaters

5 Piece(s) (MOQ)

We are offering mica nozzle heaters. Description: php mica nozzle heaters are designed and manufactured with more than 40 years of practical experience, for superior performance and life expectancy., as a manufacturer specialized in industrial electric heating elements & the desire to provide quality products and services to our customers both oem's & end users, php specializes in designing mica nozzle heaters, ceramic band heaters , mica band heaters, & strip heaters to your exact specifications. Depending upon applications php nozzle heaters are manufactured with high temperature oxidation metal sheath and high grade mica insulation resistant to moisture and high temperatures. A superior grade nicr resistance wire is evenly wound to provide uniform and reliable heat distribution with the best combination of physical strength, high emissivity & good thermal conductivity to heat machine nozzles, good for sheath temperature up to 300 deg. C. Php nozzle heaters are also available with various construction styles with special inbuilt energy saving options. features: 1. available in premium, economy & power saving options 2. conserves energy with improved heating efficiency upto 35 wattssq inch. 3. special high grade mica insulation for superior thermal conductivity and die- electric strength. 4. engineered for longer life with superior quality nichrome wire for uniform temperature & maximum amperage carrying capacity. 5. min dia available 25 mm. 6. min width available 25 mm. 7. available in various lead terminations & clampings 8. robust terminal junction with specially designed protection cap. 9. available in ms, brass, chrome nickel steel sheathing. 10. expandable to fit around the barral o.d. Easy installation & removal. 11. designed for temperatures upto 300°c. applications: 1. injection moulding machine nozzle. 2. blow moulding machine nozzle 3. all plastic & rubber processing machinery. 3 construction styles: 1. Eco-heat construction ¢ chrome nickel steel clamping with ms inner sleeve. ¢ 500 mm glass fibre insulated cable ¢ terminal protection cap, unless specified. ¢ single piece construction. ¢ clamping: barrel nut type. 2. Premium-heat construction ¢ chrome nickel steel clamping with chrome nickel steel inner sleeve. ¢ terminal protection cap, unless specified. ¢ single piece construction. ¢ 500 mm glass fibre insulated metal braided cable. ¢ clamping: barrel nut type. 3. Power saver construction ¢ chrome nickel steel clamping with brasschrome nickel steel inner sleeve. ¢ energy saving insulated cover. ¢ barrel nut type clamping with terminal protection cap, unless specified. ¢ 500 mm glass fibre insulated metal braided cable. ¢ single piece construction. electrical variations: single phase: php's band heaters are usually designed on 230 volts single phase unless specified. dual phase: mica nozzle heaters can be designed with multiple circuits to operate in single or dual-phase circuits.

...more

Mica Band Heaters

5 Piece(s) (MOQ)

We are offering mica band heaters. Description: php's mica band heaters are designed and manufactured with more than 40 years of practical experience, for superior performance and life expectancy., as a manufacturer specialized in industrial electric heating elements & the desire to provide quality products and services to our customers both oem's & end users, php's specializes in designing mica band heaters, ceramic band heaters , nozzle heaters & strip heaters to your exact specifications. Depending upon applications php's mica band heaters are manufactured with high temperature oxidation metal sheath and high grade mica insulation resistant to moisture and high temperatures. A superior grade nicr resistance wire is evenly wound to provide uniform and reliable heat distribution with the best combination of physical strength, high emissivity & good thermal conductivity to heat cylindrical parts, good for sheath temperature up to 3000c. Php's mica band heaters are also available in various construction styles with special inbuilt energy saving options. features: 1. available in premium, economy & power saving options. 2. conserves energy with improved heating efficiency upto 30 watts per square inch. 3. designed for temperatures up to 300 deg. C. 4. special high grade mica insulation for superior thermal conductivity. 5. engineered for longer life with superior quality nichrome wire for uniform temperature & maximum amperage carrying capacity. 6. available in various lead terminations & clampings. 7. robust terminal junction with specially designed chrome nickel steel protection cap. 8. expandable to fit around the barrel o.d. Easy installation & removal. 9. available in brass, chrome nickel steel & ms galvanized sheathing. applications: 1. injection moulding machinery 2. blow moulding machinery 3. film & pipe extruders 4. laboratory equipment. 5. all plastic & rubber processing machinery. 4 construction styles: 1. Eco-heat construction ¢ ms inner sleeve & steel clamping ¢ screw post terminal with ceramic cap steel protection box. ¢ single piece construction ¢ clamping : barrel nut type ¢ also available in two piece construction 2. Premium-heat construction ¢ chrome nickel steel clamping with brass inner sleeve. ¢ 500 mm glass fibre insulated metal braided cable. ¢ terminal protection box, unless specified. ¢ single piece construction. ¢ clamping : barrel nut type ¢ also available in two piece construction 3. Power saver construction ¢ chrome nickel steel clamping with chrome nickel steel inner sleeve. ¢ energy saving insulted jacket (3 mm thick) ¢ barrel nut type clamping with terminal protection box, unless specified. ¢ 500 mm glass fibre insulated metal braided cable. ¢ single piece construction. ¢ also available in two piece construction. 4. Power saver plus construction ¢ chrome nickel steel clamping with brass chrome nickel steel inner sleeve. ¢ energy saving insulted jacket (16mm thick) ¢ barrel nut type clamping with terminal protection box, unless specified. ¢ 500 mm glass fibre insulated metal braided cable. ¢ single piece construction. ¢ also available in two piece construction. electrical variations: 110 - 440v 1. single phase: php's band heaters are usually designed on 230 volts single phase unless specified. 2. dual phase: mica band heaters can be designed with multiple circuits to operate in single or dual-phase circuits.

...more

Manifold Tubular Heaters

We offer Manifold Tubular Heaters that are primarily used for Hot Runner manifolds. Manufactured for excellent performance as well as high life expectancy, the Manifold Tubular Heaters offered by us possess capability to withstand high sheath temperature. They also provide physical strength, high emissivity & good thermal conductivity to heat hot runner manifolds. The superior grade helical wound high temperature resistant NiCr alloy heating wire is swaged in Chrome Nickel Steel sheathed tubes. Further, the Threaded terminal post that provides a cold section of approx 40mm (min), is sealed with special sealing components thus prevent the heater from moisture. An accurate dimensional sketch showing centre distances, bending radius as well as path are necessity for tubular heaters. Features : CE certifiedAvailable in Chrome Nickel SteelAvailable in Dia 8mm, 8.5mm, 6.5mm & Square Section 6mm x 6mmSealed Edges to prevent from Moisture Superior Grade Magnesium Oxide Insulation Swaged for Good Electrical Insulation & Even Heat Transfer Application : Hot Runner Manifolds

...more

Low Watt Density Cartridge Heaters

5 Piece(s) (MOQ)

Available with us is Low Watt Density Cartridge Heaters that are manufactured especially for heating applications that don�t require high watt densities. Suitable to be used in any assembly equipment of machine, these Low Watt Density Cartridge Heaters are high on demand in the market. These heaters comprise of helically wound resistant coil formulated from nickel-chrome wire, properly stretched & strung through holes in a round ceramic insulator. The entire element assembly is fitted into a Chrome Nickel Steel sheath. This alloy provides the best combination of physical strength and resistance to heat oxidation up to 450oc. The longer operating heater life is also because of the high purity magnesium oxide filled in remaining space inside the insulator. Silent Features : CE CertifiedMin Dia � 3/8� & 10mm, Max Dia � 3/4� & 20mmMin Length � 50mm, Max Length � 1000mmHighly Non-CorrosiveVarious Watt Density Options AvailableEven Heat Profile & Max Temp. Up To 300oCSpecially Selected High Purity Magnesium OxideAvailable With Various Lead Exits & Cable Protection OptionsSealed Bottom End disk to avoid contamination & for easy replacements.Standard Sizes AvailableSuperior Life Expectancy Extensively Used In : Heat SealingHot StampingPlastic Injection Labeling MachinesPackaging Machinery Shoe MachineryGlue guns and Wax potsHeating of gases and liquids

...more

LOW WATT DENSITY CARTIDGE HEATERS

low watt density cartridge heaters superior life expectancy highly non-corrosive various watt density option available standard sizes available specially selected high purity magnesium oxide php’s low density cartridge heaters are developed for heating applications not requiring high watt densities nor sheath temperatures exceeding 300°c, with maximum watt densities of 30 to 45 watts per square inch depending on applications. The heaters of various sheath diameters can be used in any assembly, equipment or machine. the heater design consists of a helically wound resistance coil made from nickel-chrome wire, evenly stretched and strung through holes in a round ceramic insulator. The element assembly is inserted into a chrome nickel steel. This alloy provides the best combination of physical strength and resistance to heat oxidation up to 450°c. specially selected grain size and high purity magnesium oxide is used to fill all remaining space inside the ceramic insulator to increase thermal conductivity, dielectric strength, and provide longer operating heater life. the heaters are used in operations involving: packaging machinery, labeling machines, plastic injection, shoe machinery, heat sealing, hot stamping, glue guns and wax pots, heating of gases and liquids and various other heating applications. low watt density cartridge heater - applications packaging industry medical & laboratory apparatus hot runner bushings shoe making industry marking & sealing machinery die and platents low watt density cartridge heater - technical data outer sheath material chrome nickel steel, welded end disc washer of same material. maximum operating temperature 300°c. heating conductorx nicr 80:20 power ± 10% voltage 12 to 440 volts leakage current < 0.5 ma high voltage 800 v surface loading upto 30 watts/in2 lead orientation a) crimped on leads : ptfe/ fibreglass flexible leads crimed on solid pin emerging from from the heater. b) fixed in leads : flexible fibre glass or ptfe leads emerging from within the heater

...more

Immersion Water Heater

Plain tubular heaters are available in straight lengths or bent as per customers requirement with threaded stud connection at both ends. Finned tubular heaters have enlarged surface area to help faster dissipation of heat.

Voltage : Upto 415 V

...more

High Watt Density Cartridge Heaters

5 Piece(s) (MOQ)

Pratik Heat Products Pvt. Ltd is engaged in offering CE certified High Watt Density Cartridge Heaters that are appreciated by our world wide clients. We have 40 Years of practical experience and have been sucessfullying offering the clients with PHP Cartridge Heaters ensures highest quality standards. This High Watt Density Cartridge Heater is widely appreciated for its durability, efficiency, high operating temperature, non-corrosive body, flawless finish, bottom end welded with disc washer and power saving quality. NiCr of higher grade is evenly wound over a supporting core that is filled with high purity magnesium oxide and is then compressed into a homogenous mass. High Watt Density Cartridge Heater that we offer is priced reasonably. Silent Features : CE CertifiedMin Dia - ¼� & 6mm, Max Dia - 1� & 20mmMin length � 1 1/2� & 40mm, Max length � 40� & 1000mmRobust Terminal with choice of ExitsSealed Bottom with Conical End disk to prevent contamination and for easy replacementsAvailable with in-built Thermocouple.Even heat profile & Max temp up to 750oCVarious Watt Density option availableStandard sizes availableHighly Non-corrosiveSuperior Life expectancyAvailable with various Lead Exits & Cable Protection optionSpecially selected High Purity Magnesium Oxide Applications : Hot Runner BushingsMarking & Sealing MachineryPackaging IndustryMedical & Laboratory ApparatusShoe Making IndustryDie and platents

...more

HIGH WATT DENSITY CARTIDGE HEATERS

php’s high watt density cartridge heaters are designed and manufactured out of experience of many years, thus the performance and life expectancy superseeds other cartridge heaters.heating conductor grade nicr 80:20 is evenly wound over a supporting core which is centrally located in a chrome nickel steel tube and the inner space is filled with specially selected high purity magnesium oxide. This assembled unit is then highly compressed, converting the core, powder and conductor into a homogenous mass. The bott om end of the heater is welded with a disc washer to prevent contamination. high watt density cartridge heater - applications hot runner bushings marking & sealing machinery packaging industry medical & laboratory apparatus shoe making industry die and platents high watt density cartridge heater - features min dia: 1/4" & 6mm, max dia: 1" & 20mm specially selected high purity magnesium oxide min length: 1½” & 40 mm standard sizes available max length: 40” & 1000 mm superior life expectancy available with in built thermocouple available with various lead exits & cable highly non-corrosive protection options various watt density option available sealed bottom with conical end disk to avoid even heat profile & max temp up to 750°c contamination and for easy replacementsphp’s high watt density cartridge heaters are designed and manufactured out of experience of many years, thus the performance and life expectancy superseeds other cartridge heaters.heating conductor grade nicr 80:20 is evenly wound over a supporting core which is centrally located in a chrome nickel steel tube and the inner space is filled with specially selected high purity magnesium oxide. This assembled unit is then highly compressed, converting the core, powder and conductor into a homogenous mass. The bott om end of the heater is welded with a disc washer to prevent contamination. high watt density cartridge heater - applications hot runner bushings marking & sealing machinery packaging industry medical & laboratory apparatus shoe making industry die and platents high watt density cartridge heater - features min dia: 1/4" & 6mm, max dia: 1" & 20mm specially selected high purity magnesium oxide min length: 1½” & 40 mm standard sizes available max length: 40” & 1000 mm superior life expectancy available with in built thermocouple available with various lead exits & cable highly non-corrosive protection options various watt density option available sealed bottom with conical end disk to avoid even heat profile & max temp up to 750°c contamination and for easy replacements

...more

High Performance Nozzle Heaters

5 Piece(s) (MOQ)

We are one of the prominent Manufacturer, Supplier and Exporter of a wide assortment of PHP High Performance Nozzle Heaters. The High Performance Nozzle Heaters offered by us come with inbuilt thermocouple and a rugged clamping offering high emissivity and physical strength. These High Performance Nozzle Heaters are good for sheath temperature up to 400oC. Our range of High Performance Heaters offers a max temp up to 250 Deg C. Besides, these heaters control sensitive materials like Nylon 66 with 40% glass filled accurately. Features : CE Certifiedwith built in ThermocoupleVery Robust DesignHigher Operating Temperature 400oCNegligible Effect of Material SpillageDelivers Better & Even Heat Transfer Available with built in ThermocoupleGood for processing engineering plastics( nylon66, glass polyfill) Applications : Extended NozzlesInjection & Blow Moulding machine nozzles Advantages : Built in Thermocouple for Accurate Temperature Control at the nozzle tipHigher operating temperature (4000Cmax)compared to conventional Mica Band Heaters (250oC max)Good for processing engineering plastics ( nylon66, glass polyfill)Quick ramp up of temperature due to higher watt densityNegligible effect of material spillageEfficient & even heat transfer due to inner Brass Collet

...more

FORMED TUBULAR HEATERS

ffortless forming for Easy installation Maximum sheath contact (upto 75%) Rapid heat transfer and distribution Minimal temp. variance between heater sheath & manifold Reduced energy costs Smaller bending radiusFormed Tubular Heaters is supplied in Chrome Nickel Steel with nominal sheath diameter of 6.50mm and 8.00mm. Standard elements have a terminal post which gives a cold section of approx 30mm for 6.50mm and 35mm for 8.00mm.The helical wound heating wire is made of a high temperature resistant NiCr alloy. And the insulation consists of superior grade of magnesium oxide (MgO). As the heaters are swaged, even at high sheath temperature they have excellent electrical insulation and a high heat transfer. To prevent the heater from moisture the connection ends are sealed with sealing components.For manufacturing formed elements it is necessary to have an accurate dimensional sketch showing all the centre distances, radius and degrees. FORMED TUBULAR HEATER - APPLICATIONS Hot Runner Manifolds FORMED TUBULAR HEATER - FEATURES Available in Chrome Nickel Steel Swaged for Good Electrical Insulation & Heat Transfer Sealed Edges to prevent from Moisture Available in Dia 8.5 mm, 8 mm, 6.5 mm & square section Superior Grade Magnesium Oxide Insulation 6 mm x 6 mm FORMED TUBULAR HEATER - APPLICATIONS Hot Runner Manifolds FORMED TUBULAR HEATER - FEATURES Available in Chrome Nickel Steel Swaged for Good Electrical Insulation & Heat Transfer Sealed Edges to prevent from Moisture Available in Dia 8.5 mm, 8 mm, 6.5 mm & square section Superior Grade Magnesium Oxide Insulation 6 mm x 6 mm

...more

FLEXIBLE TUBULAR HEATERS

25 - 50 Per Piece

flexible tubular heater - features effortless forming for easy installation maximum sheath contact (upto 75%) rapid heat transfer and distribution minimal temp. Variance between heater sheath & manifold reduced energy costs smaller bending radius flexible tubular heater - technical specifications sheath material - stainless steel sheath temperature of heating element - max. 700 °c standard voltage - 230 v high voltage test - 1000 v ac insulation resistance - ≥5 mω at 500 v dc leakage current - < 0.5 ma at 253 v ac wattage tolerance - ±10% length tolerance - ± 1.5% groove dimensions - for 8 mm: 7.80 (±0.05) mm x 8.00 (±0.10) mm for 8.5 mm: 8.30 (±0.05) mm x 8.50 (±0.10) mm

...more

Coil Heaters

5 Piece(s) (MOQ)

Available with us is an exclusive gamut of CE Certified Coil Heaters designed for Hotrunner systems with Premium Materials and Tight Manufacturing controls. These heaters are also known as cable heaters or Hotrunner heaters. An advance concept of thermal engineering, this heater has a construction similar to high watt density cartridge heaters. With our 40 years of practical experience, we are offering PHP Heaters that ensure highest quality standards, superior performance and life expectancy at higher temperatures. Also, Coil Heaters offered by us is available at the economical prices. Features : CE CertifiedStandard sizes available with various cross sectionVarious Watt Density options available.Robust Design with Choice of Terminal Exits Available with built in ThermocoupleDesigned for even heat profilePrecision fit on Hot Runner Nozzles & ManifoldsHighly Non-corrosive Maximum heat transfer due to more contact areaAdvanced Thermal Engineering Coil Heater Terminal Exits : AxialRadialTangential Applications : Hot Runner Nozzles & BushingsHotrunner Injection mouldsInjection & Blow Moulding Machine NozzlesPET prefrom & Thin wall container MouldsHotrunner Manifolds Dimensions : Size (mm)2.93.33.83.33.3 x 3.31.8 x 3.22.2 x 4.22.5 x 4.34 x 6.4Cold Zone (mm)2.93.33.83.33.83.33.33.86Adapter Diameter (mm)5.57.57.577.57.57.57.510Adapter Length (mm)2232322.53232323240Crimp Diameter (mm)7.59.59.59.59.59.59.59.512Maximum Length (mm)200020003000200030002000200030003000Maximum Current2.5A5A5A5A5A5A5A5A10AMin. Coiling Dia. (mm) 810128108101030Built in T/CNoYesYesYesYesNoYesYesYes

...more

Ceramic Band Heaters

5 Piece(s) (MOQ)

We are offering ceramic band heaters. Description: php's ceramic band heaters are designed and manufactured with more than 40 years of practical experience, for superior performance and life expectancy. As a manufacturer specialized in industrial electric heating elements & the desire to provide quality products and services to our customers both oem's & end users, php specializes in designing ceramic band heaters , mica band heaters, nozzle heaters & strip heaters to your exact specifications. Depending upon applications php ceramic band heaters are manufactured with high temperature oxidation metal sheath and high grade steatite insulators to withstand high temperatures. A superior grade nicr resistance wire coil provides uniform and reliable heat distribution with the best combination of physical strength, high emissivity & good thermal conductivity to heat cylindrical parts, good for sheath temperature up to 5000c. Php ceramic band heaters are also available with various construction styles with special inbuilt energy saving options. features: 1. available in chrome nickel steel with power saving options. 2. special high grade steatite insulators for superior thermal conductivity. 3. power saving up to 30%. 4. designed for higher temperature up to 500°c. 5. robust terminal junction with specially designed protection cap. 6. efficient heat transfer even on irregular surfaces in comparison to mica band. 7. conserves energy with improved heating efficiency up to 55 watts per square inch. 8. engineered for longer life with superior quality nichrome wire for uniform temperature & maximum amperage carrying capacity. 9. reduces down time for replacements. 10. easy installation and removal. 11. available in various lead terminations & clampings expandable to fit around the barrel o.d. applications: 1. injection moulding. 2. film extruders. 3. blow moulding. 4. plastic & rubber processing machinery. 5. laboratory equipment 3 construction styles: 1. Premium-heat construction standard features for premium-heat construction suggested watt density 35 to 40 wattssq. Inch chrome nickel steel sheathing with 4mm thick heat saving thermal insulation single piece construction 500 mm long insulated metal braided flexible leads. barrel nut type clamping with terminal protection box. total wall thickness 12mm min requirement : i.d. 60mm, width 35mm also available in two piece construction. 2. Power saver construction standard features for power saver construction suggested watt density 40 to 45 watts sq inch. chrome nickel steel sheathed with 16mm thick twin insulated cover single piece construction. 500 mm long insulated metal braided flexible leads allen key barrel nut type clamping with terminal protection box. total wall thickness: 25 mm. also available in two piece construction. min requirement : dia. 75mm, width 75mm 3. Power saver plus construction standard features for power saver plus construction suggested watt density 50 to 55 watts sq inch. chrome nickel steel sheathed with heat optimizing insulated cover. single piece construction. 500 mm long insulated metal braided flexible leads barrel nut type clamping with terminal protection box. total wall thickness : 45mm min requirement: i.d.: 100mm, width 100mm. also available in two piece construction. electrical variations: single phase: php's band heaters are usually designed on 230 volts single phase unless specified. dual phase: ceramic band heaters can be designed with multiple circuits to operate in single or three-phase circuits. three phase: on very high wattage band heaters it would be advantageous to install three-phase wiring to reduce the current load across a single conductor. Three-phase wiring is available with all types of insulation, construction styles, and clamping variations. limitations: minimum width: 3"(76.2mm).

...more

Cartridge Heating

Voltage : 12 to 440 volts

Brand Name : PHP

Power : ± 10%

...more

Band Heaters

Cartridge Heaters

Industrial Heaters

Be first to Rate

Rate ThisOpening Hours