Pre-Engineered Building Structure

Get Price Quote

1 Set (MOQ)

You may get a variety of colours at BIGWIN BUILDSYS COATED PRIVATE LIMITED that will meet your needs. All you have to do is get in touch with us, and we'll make sure to take your order and deliver it to your location. We are a well-known Steel Coated Material supplier, which speaks volumes about the calibre of the goods and services you can expect from us. We are Steel Coated Material Suppliers in Mumbaiand our coated steel sheets are ideal for a variety of uses in the construction sector because of their various qualities. Strength, jointability, paintability, and economy are all included in these colour-coated steel sheets and coated wall panels. Because colour-coated sheets offer exceptional corrosion resistance, they are now the material of choice for many different types of building projects, including roofing and walling. We are Wholesale Steel Coated Material Suppliersproviding steel sheets with coatings that are a distinctive construction material. These coloured steel sheets combine the corrosion resistance of zinc or zinc/aluminium alloy coatings with the strength of steel. These colour-coated sheets may be fashioned into a variety of ornamental and structural architectural elements by being punched, pressed, roll-formed, and linked. Customers laud our goods for their great performance, obstruction-free operation, and prolonged useful life. With the aid of the most recent equipment and tools put into use at our production facility, we are able to provide these items. To achieve the goals established by the organisation, we asSteel Coated Material Suppliers in Indiaare working in good coordination. The diverse sectors mostly want the items we supply. To meet the wide range of needs and demands of our cherished consumers, we are providing these items in a variety of styles.

Pre Engineered Buildings Service

Get Price Quote

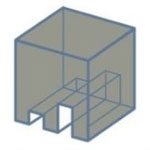

Pre-Engineered Buildings are the state of-the-art steel solution to developing an efficient and cost-effective infrastructure. PEB's offer ultimate design flexibility and an extremely short construction time (right from initial design to completion). They are supplied as a fully furnished product along with steel structure, roofing, cladding and building accessories. They require no on-site fabrication or welding - they can simply be bolted together as per specifications. PEB's are best suited for warehouses, sports halls, factories, workshops, distribution centers, cold storages, supermarkets, metro & mono rail stations, aircraft hangars or any good + multistorey construction. PEBs save HALF the construction time. Usability of the building can be started earlier enabling faster return on investment (ROI). Design flexibility and completely customizable in shape, cost and use Superior aesthetic value, better rainwater drainage and connection to RCC structure Savings in cost of civil work. PEBs are lighter in weight thereby requiring lesser civil work. No site fabrication required. Site work is minimized and largely hassle-free. Vertical clearance from the floor can increase significantly from eaves to ridge creating more volumetric parameters. PEB can be dismantled, at ease and can be re-erected at a different location. Entire gamut of activities starting from inception to completion are being undertaken by a single entity resulting in efficient project control.

Best Deals from Prefabricated Building

PEB Structure

120 - 150 Per KG

100 TON (MOQ)

PEB Building Structure

150 - 700 Per Square Feet

10000 Square Feet (MOQ)

In structural engineering, a pre-engineered building (PEB) is designed by a PEB supplier or PEB manufacturer with a single design to be fabricated using various materials and methods to satisfy a wide range of structural and aesthetic design requirements. Optimum cost Premium products Speedy and efficient process Functional versatility & architectural flexibility Low maintenance and operating cost.

Pre Engineered Steel Buildings

290 - 370 Per sqft

Pre Engineered Building

Get Price Quote

1 Ton (MOQ)

Prefabricated Building

Get Price Quote

As a renowned Manufacturer, Supplier and Exporter of Prefabricated Building, we bring you a wide range of immaculate quality. We use only high-grade raw materials in manufacturing to ensure that our product meets the highest quality standards. Its features such as optimum design and durability make it an interesting proposition. It is widely applied for commercial purposes as well as domestic purposes. Get in touch to avail reasonable rates.

prefabricated metal building

Get Price Quote

Sheet Molding Compound, is a composite material or fiber-reinforced plastic made of a plastic reinforced by fine fibers made of glass. Like graphite-reinforced plastic, the composite material is commonly refered to by the name of its reinforcing fibers (fiberglass). The plastic is thermosetting, most often polyster or vinylester, but other plastics, like epoxy(GRE), are also used. The glass is mostly in the form of chopped strands mat (CSM), but woven fabrics are also used.

Building Structures Repair Powder

Get Price Quote

Coarse grained mortar for repair of heritage structures. DESCRIPTION : Perma Heritage Mortar-10 is a light brown colored powder which when mixed with water forms a pasty consistency mortar. This mortar is used for building up surfaces and repair of architectural features in a building exterior, where the depth of repair is more than 10 mm. The product is based on hydraulic lime, compatible polymers and fillers. Though the product is very slow in setting and strength development, which is the primary quality of hydraulic lime, it achieves good strength and durability parameters with age. PRIMARY USES : Perma Heritage Mortar-10 is used for creating architectural features in the building exteriors. It is used for repairing historic structures which are composed of non cementitious mortars and concretes. This mortar has low shrinkage characteristics and hence does not develop shrinkage stresses over the repaired substrate and hence is safe and durable. DIRECTION FOR USE : Clean the surface to remove dirt, dust, laitance, oil, grease etc. Dampen the surface wherever it is dry. Mix the Heritage mortar with water in the recommended proportion of water to form a smooth consistency paste. Apply this paste on the surface to be repaired and scratch the surface to take the next layer of mortar upon drying. This product is applied in thin layers of 8 to 10 mm. If there is a need to build up the thickness, then it is applied in layers allowinnish is done with Heritage Mortar – 5. Final first layer to dry before application of the subsequent layer. This mortar can be put in layers of 10 mm to build up the thickness PACKING : Perma Heritage Mortar -10 is available in 25 kg & 50 kg packing. SHELF LIFE : Perma Heritage Mortar -10 has a shelf life of 12 months from the date of manufacture.

Pre Fabricated Buildings

Get Price Quote

We are the pioneering supplier of panel-based cold storages in India. Our insulated sandwich panels provide superior insulation, are fire-resistant, very lightweight and extremely durable. With hundreds of installations across India, our extensive and growing customer list is proof of our success in the cold storage arena. Our sandwich-panel based cold storage offers the following advantages: Superior insulation property,Fire resistance,Quicker construction (and quicker loan payback)

Pre Engineered Buildings

Get Price Quote

2000 Square Meter (MOQ)

Satec’s commitment to excellence makes it India’s leading choice for manufacturing and installing pre-engineered buildings. Pre- Engineered Buildings are an efficient and economical solution to modern infrastructure needs. These steel buildings can be customised as per requirements offering design flexibility and durability. Lighter than conventional steel buildings, Pre-Engineered Buildings offer potential savings in structural framework. Pre-Engineered Buildings offer huge savings in time, as not only can they be constructed faster than conventional buildings, standardisation of PEB has led to significant reduction of design time. At Satec, our Pre-Engineered Buildings consist of the following : The main frames (includes H Beams, Slant Beams and Box Beams) Secondary framing (Z and C purlins) Roof and wall panels (single skin and insulated sandwich panels) Structural subsystems (canopies, fascias, partitions, etc.) Floor systems (mezzanines,, platforms, etc.)

Pre Engineered Buildings

Get Price Quote

Pre Engineered Buildings are custom made to suit a wide range of application in different industry sectors. It largely depends upon the requirement of the customers. They are also called Pre-Engineered Metal Buildings (PEMB) in some industry sectors. These metal buildings are different from conventional buildings in ways like speed in delivery and erection, flexibility in expansion and withstand severe weather conditions. We are a one stop solution provider for all your structural needs and have products ranging from Porta cabins, Canopies, Mezzanine Floors, Stairs, etc. Having an experience of over two decades in this industry. We truly comply with all the ISI specifications while designing and manufacturing all our structures which ensure all-out safety and are quite economical as well, as we incorporate quality raw materials and sheets in their making. Over the last few decades pre-engineered steel and metal buildings have become quite popular in the construction industry due to its flexibility, durability and adaptability over. These factors have made steel one of the most sought after materials for building construction. Our customer has large choice for sheet material which can suit their budget as well as requirement such as pre-coated sheets, Sandwich Panel GI sheets, Fiber sheets, and Polycarbonate Sheets. In the pre-engineered building systems one has the flexibility to accomplish indefinite array of building configurations, custom designs, requirements and applications. Factory sheds, warehouses, green houses, community halls and canopy etc., are some of the ways where the PEB systems can be applied. STRUCTURAL SYSTEMS FOR PEB It’s the structural system that determines the speed and flexibility of the pre-engineered steel/metal buildings. Steel column and beam segments fabricated and painted in a factory and that are merely attached together at the site are part of this system. The beams and columns having an end plate with holes for attaching at both ends are custom fabricated I-section members. Their making includes steel plates that are cut as per desired thickness and then welded together to make I sections. CNC machines are used for cutting and welding due to the speed and precision they offer. The operators just require feeding a CAD drawing of the beams into the machins. As a result of this production line style of work, the speed and consistency in fabrication enhances to a great deal. For getting optimal structural efficiency, one can tailor the shape of the beams as well. The beams are deeper where the forces are greater and shallow where they aren’t. This type of construction is different from the conventional ones. PEB COMPOSITION Our customer has large choice for sheet material which can suit their budget as well as requirement such as Each piece of the PEB system is quite similar. A crane is used to lift the painted steel sections, and they are then attached together by construction workers who climb to the suitable position. In the construction of huge buildings, we make use of two cranes that work from both ends. When the job of one crane is done, it’s taken away with the other finishing the work. This construction demands the installation of around 6 to 20 bolts that need to be tightened further so as to accurately match the amount of spin using a spin wrench. WE ALSO TAKE SERVICE CONTRACT FOR FOLLOWING WORK : Maintenance for shed and building structure Fastest delivery time & speedy erection Transported in knock down condition

Pre Engineered Building

Get Price Quote

We are the leading manufacturer and service provider of pre-engineered building. A pre-engineered building system can be as unique as your needs. These buildings are intended primarily for commercial, industrial or institutional occupancies.

Portable Homes and Buildings

Get Price Quote

In day today life man needs are increasing day by day and basic necessity of Shelter and Storage increasing instantaneously.The basic needs of shelter for temporary purpose or places where there are no physical amenities (Infrastructure) to stay. Such asForests area, Deserts area,Uncontrollable Environment area and in Non-Suitable climate area we have the need of Portable Home.The Prefabricated Houses are the best way to fulfill this necessity. We can also use this in our home’s backyard in Gardens or as Portable Storage Unit. Portable Homes are also known by different names in different places such as Prefab Modular Homes, Demountable Homes, Amish portable houses or Movable Houses etc. These Affordable houses are Constructsuch that it can Control Climate.Means it can’t Effect with outdoor climate because the purpose of this houses is to protect from high temperature or with low temperature as preferable and Compatible in all climates andcontains all basic necessity such as Built-in Bathrooms, Toilets, canteen and all types of Customization as per Customer Requirements. What are Portable Buildings? If we have plenty of people with us to work as a team or any type of organization or our work is fully depending on Migration Such as Military Camping or for Migrant people like Amish Mennonite peoples then we have the big issue of Shelter for all people, so resolvethis problem by an excellent choice of Portable Buildings also known as many names Such as Prefabricated Buildings, Modular Buildings, Temporary Buildings, Transportable Buildings, Demountable Buildings, Relocatable Buildings, etc. These Buildings are low expensive and affordable as compare to Conventional buildings and can be utilize as many ways Because it has many utilitieshence it is also known as Utility Portable Buildings. Why should youbuy these products from Aster Prefab? Aster Prefab the largest Manufacturers and Sellers of portable homes and buildings as well as we have wide variations in prefab portable buildings andmodular houses. We have Quality Assurance team for verifying and validating the quality of Product andMaterial used. Civil Engineers for designing the Movable Buildings and Homes plan according to Customization as per Requirement of Customers.Group of Experienced andExperts of Carpenters, Electrician, Painter, Interior and Exterior Decoratorsas in affordable Prices with Transportation facilities.Mobile buildings are typically construct in our workshop construction work can take minimum ten days or sometime it may take maximum forty to forty-five days also. We divide work into modules completed modules are transported to the destination fitted by the crane as per customer requirements. Points which makes us different from others: Quality Assurance:We have team of qualified experts only for testing of products in different criteria. Material Quality: We use high quality materials. Materials we used are Wood-frame floors, Metals, Steel, Paints, etc. Transportation: We have vehicles like Crane, Truck so transportation setup is easy affordable for customers. Warranty: We make the quality with Strength of portable cabins hence We give warranty on our portable accommodations. Types of Portable Buildings: Single story units:In British’s language single story means only ground floor. We give all features and facilities to our customers in their single story’s according to thecustomization and requirement’s. Two story units:Two story contains ground floor + one floor with all facilities and amenities according to costumer’s customization and requirements. Looking for Portable Home manufacturers? Features and Facilities: Climate resistance. Movable and easy to transport anywhere. Corrosion resistance. Water storage tank. Water geyser for hot and cold water. Modern and well-favored interior design. Modern and well-favored electrical wiring. Best quality products as per ISO 9001. Fire Protection (Optional). Air condition (Optional). Civil Look (Optional)

Prefabricated Buildings

Get Price Quote

Valisons & Co are the leading manufacturer and suppliers of Prefabricated Units Houses buildings through out India. The conventional method of building a structure is to transport bricks, timber, cement, sand, steel and construction aggregate, etc. to the site, and to construct the houses on site from these materials. In prefabricated construction, only the foundations are constructed in this way, while sections of walls, floors and roof are prefabricated (assembled) in a factory (possibly with window and door frames included), transported to the site, lifted into place by a crane and bolted together.

prefabricated portable building

Get Price Quote

We are manufacturers & suppliers of potable cabin,potable office cabin,porta cabin,site office cabin,bunk house,prefabricated cabin,security cabin,portable toilet cabin,portable kitchen & portable accommodation cabin as per customer requirement in ms steel. These porta cabin have long life ,low maintenance ,very easy to set transport & cost effective.

Prefab Labour Toilets

27,500 Per Piece

100 Piece (MOQ)

Portable classroom

Get Price Quote

Portable classroom, Portable office containers, bunkhouses

Pre Engineering Building

Get Price Quote

Pre Engineering Building, Porta Cabin

modular buildings

Get Price Quote

We are offering modular buildings

Pre Engineering Building

Get Price Quote

Pre Engineering Building, Building Materials, C Channels, drywall partition

Pre Engineered Buildings

Get Price Quote

Pre Engineered Buildings, ELEVATOR, Elevator Control Panel

modular buildings

Get Price Quote

modular buildings, Light Steel Buildings, Modular Kitchen Baskets

Pre Engineered Building

Get Price Quote

Pre Engineered Building, C Purlin, civil construction

pre engineered building service

Get Price Quote

pre engineered building service, Warehouse Construction

modular building

Get Price Quote

modular building, Containerized Office Portable Cabin

pre engineered metal buildings services

Get Price Quote

pre engineered metal buildings services, metal beams

Pre Engineered Building

Get Price Quote

Pre Engineered Building, Prefabricated tubular structure, Industrial Shed

Prefabricated Steel Buildings

Get Price Quote

Prefabricated Steel Buildings, rockwool panels, eps panels

Pre Engineered Building Sheds

Get Price Quote

Pre Engineered Building Sheds, Polycarbonate Corrugated Sheet