Wire Rope Sling

A wire rope sling is only as good as its end termination. To produce a safe and reliable wire rope sling involves more than just 'having a press', a length of wire rope and fittings. Since 1958 Premier Mill Stores Co. Pvt. Ltd. has manufactured wire rope lifting slings and we are proud to have an impeccable safety record.Our testing equipment is approved by the Inspector of Factories, Director General and Chief Inspector Dock Safety for conduction load tests by a certified competent person. Our slings meet local and international performance standards and can custom and design a sling to suite your applications with professionals having a sound technical expertise. Our engineers can visit your locations and suggest the right sling for your applications. FACILITIES INCLUDE: A fully equipped sling unit with the latest state of art technology comprising proof load testing machine up to 100 tons, Hydraulic splicing machines (500 Tons, 1000 Tons and 3000 Tons) capable of splicing up to 56 MM Dia wire rope, above 56 mm we can manage from our principle principal Usha Martin stock of end terminal to suite your applications. Over the years, we have developed technical expertise and have a skilled man force capable of making Hand spliced wire rope slings, endless grommet, long splice, Flemish Eye splicing, Cable laid slings and special type slings as per customer requirement. Our Products are duly certified by LLoyds, ABS, IRS, API, CGS, RITES, BHEL, KIOCL, SAIL, BEML, QUEST MECHANICAL FERRULE SPLICED WIRE ROPE SLINGS AS PER IS 5245 (PART II) 1970 TYPES OF SINGLE PART SLINGS

...more

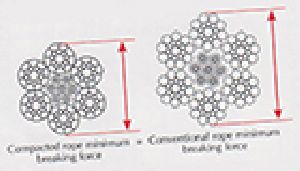

POWERFORM COMPACTED ROPE

A Powerform® compacted rope is a steel wire rope which has been manufactured using individually compacted strands.During the compaction process the outside diameter of the strand is reduced and steel moves into the empty voids between the wires within the strand. The forming process also produces a very smooth exterior strand surface. The resultant rope has a very high steel fill factor and consequently a relatively high minimum breaking force for any given diameter when compared with a conventional rope. The compacted strand has very favourable internal contact conditions when compared with the point contact of round wires within a normal strand. Exterior contact conditions are equally favourable. The smooth surface of the compacted rope offers a wider bearing surface to the sheave or drum groove.Inter strand contact and contact between adjacent laps of rope on the winch drum is also improved. Usha Martin compacted ropes are referred to as "Powerform®" and are available in a number u constructions. COMPACTED ROPES CHARACTERISTICS SIMPLY STATED Increased breaking force Increased performance Improved characteristics Improved wear resistance Improved crushing resistance Improved Bend Fatigue resistance

...more

Indef C P Block P Type

ISI marked manufactured in ISO 9001: 2000 certified company Assured quality & interchangeability of parts Tested as per ISI procedure for 50% over load Assured safety Grade 80 load chain & M.S. hand chain Longer chain life Rugged German design, in use for more than 30 years Assured reliability Double ball bearing supported load wheel Smooth operation Precision machine case hardened alloy steel gears Long life, noiseless operation Fully pocketed S.G. iron cast load chain wheel Long life, safe and smooth running Anti corrosive powder coated zinc plated parts Anti rust & better aesthetics

...more

Indef C P Block M Type

Light weight & sturdy Ease of handling Lifelong lubrication Minimal maintenance required Surface hardened gears Extended working life Use of needle roller bearings High operating efficiency Smooth passage of load chain Machined guide rollers Smooth hand chain operation Unique cover design Self sustaining maintenance free friction brake Reduced downtime Grade 80 load chain for strength & wear resistance Longer chain life Anti corrosive powder coated finish Better aesthetics

...more

Elevator Rope

No other application of steel wire ropes demands such close manufacturing tolerances and such high quality in Materials as the elevator industry. No other industry demands such high safely factors. These ropes are designed to satisfy most OEM specifications and are available for main suspension, governor and compensating duties. TENSILE GRADESSingle Tensile 1570 or Dual tensile 1370 (outer) / 1770 (inner) (other grades are available on request) WIRE SURFACEBright or Galvanised. ( If not specified bright will be supplied ) ROPE COREFibre - Sisal Fibre or otherwise as specified steel - CWR (IWRC) LUBRICANTIronside 60 / Nyrosten T55 or customer specified lubrication confirming to ISO 4346 ROPE USAGEHoist ropes ( suspension ropes), compensating ropes, Governor ropes GOVERNOR ROPES6x25F6x19 Classification + Fibre core (CFN) GOVERNOR ROPES8x19 S+ Fibre core (CFN) HOIST & COMPENSATING ROPES6x19 classification + Fibre core (CFN) HOIST & COMPENSATING ROPES 8 x 19 S+ Fibre core (CFN) HOIST & COMPENSATING ROPES8 x 19 S+ IWRC (8 x 7 + CF)

...more

lifting pulley block

Polyester Webbing Slings

Webbing Slings

Polyester Slings

Pulley Block

Steel Wire Thunder Hose

PVC Lay Flat Hose

sanitary hose

PVC Oil Suction Hose

Rubber Transmission Conveyor Belting

PowerForm Selection rope

OPTIMISED CRANE DESIGN The high breaking load to size relationship can allow crane manufacturers to optimise the design of crane components such as the winch drum and sheaves whilst still complying with international crane design standards. LONG LIFELaboratory fatigue testing indicates that it is possible to achieve up to two times normal rope life when comparing a Powerform" rope with a conventional rope of equivalent construction. GREATER RESISTANCE TO CRUSHING IN MULTI-LAYER COILING SITUATIONSPowerform® ropes are recommended for all multi-layer coiling situations where crushing on lower layers is inevitable. The more solid cross section of the Powerform" rope offers much greater resistance to this type of damage. MORE EFFECTIVE RESISTANCE TO CRUSHING AT CROSSOVER POINTSBecause of the higher steel fill factor Powerform" ropes offer much better resistance to crushing damage at crossover points on the winch drum. GREATER RESISTANCE TO "INTERFERENCE" AT THE DRUMAbrasive wear between adjacent laps of rope which is normally most severe where the rope moves on and off the drum can be minimised by using a Powerform* rope. REDUCED WEAR ON SHEAVESThe smooth exterior of the Powerform" rope can lead to reduced abrasive wear on both the sheave and rope.

...moreBe first to Rate

Rate This